Material drawing claw structure of novel glazing bead saw

A technology of glass beading and material claws, which is applied in metal processing and other directions, and can solve the problems of production efficiency decline and production cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

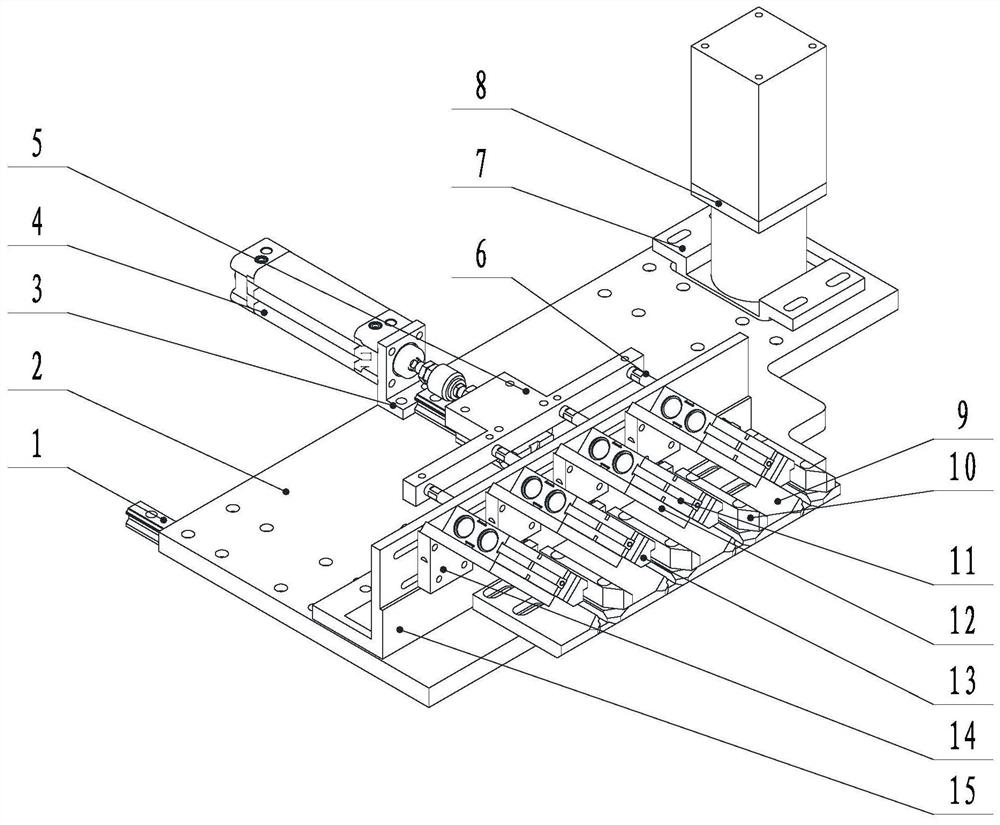

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] Such as figure 1 As shown in the drawing, a new type of drawing claw structure for glass bead saw, including a square rail 1, a supporting plate 2, and a pressing cylinder 11, the supporting plate 2 is installed on the slider, and the supporting plate 2 is installed with a servo Motor 8, the cylinder block 3 is installed on the supporting plate 2 by bolts, the cylinder 4 is installed on the cylinder block 3, the cylinder rod on the cylinder 4 is connected to the connecting plate 5 by bolts, and the other side of the connecting plate 5 is connected by bolts N feed shafts 6, the feed shaft 6 passes through the through hole on the support base 15, the other end of the feed shaft 6 is bolted to the feed head, the servo motor 8 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com