A six-layer wiring lcp packaging substrate, manufacturing method and multi-chip system-in-package structure

A technology for encapsulating substrates and substrates, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device parts, semiconductor devices, etc., to achieve excellent high-frequency transmission characteristics, reduced use, low moisture absorption and water permeability, and oxygen transmission rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

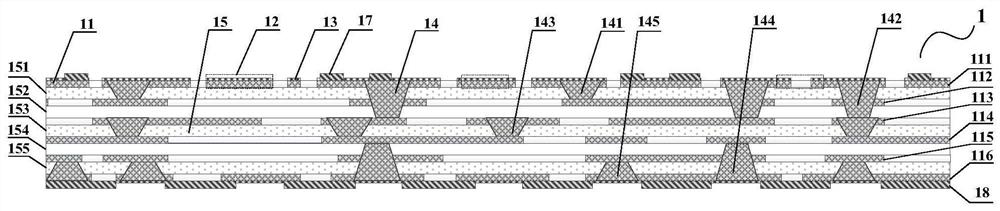

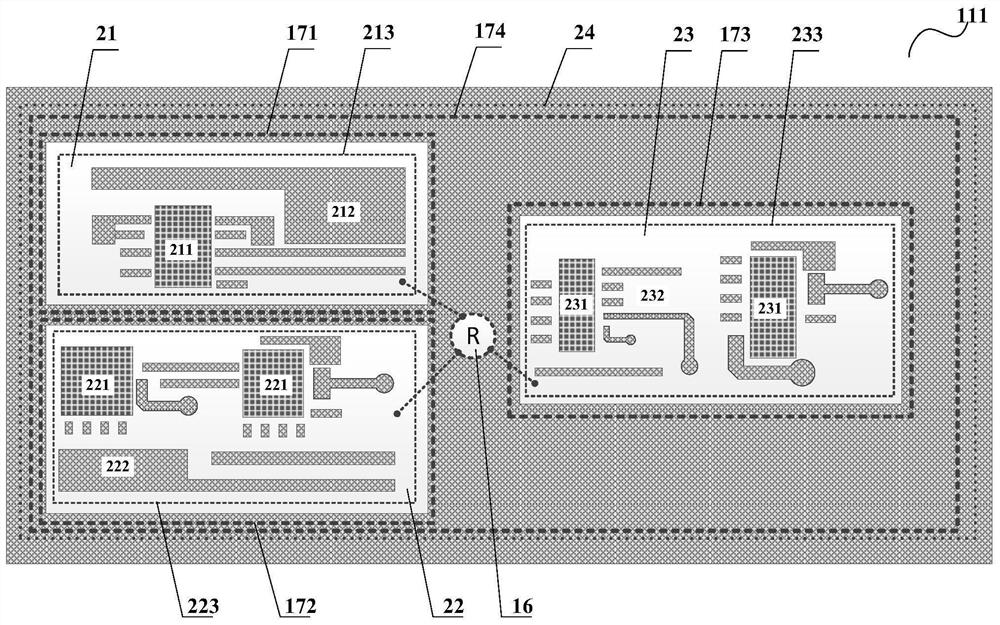

[0077] Such as figure 1 As shown, a six-layer wiring LCP packaging substrate of this embodiment includes:

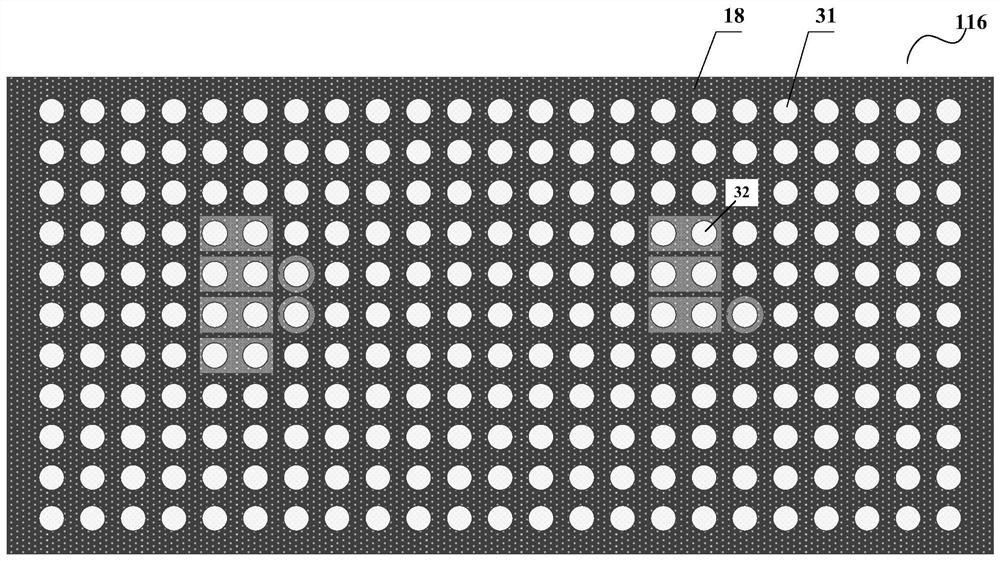

[0078] 6 layers of patterned metal circuit layers distributed from the surface to the bottom surface, followed by the first layer of patterned metal circuit layer, the second layer of patterned metal circuit layer, the third layer of patterned metal circuit layer, and the fourth layer of patterned metal circuit layer layer, the fifth layer of patterned metal circuit layer and the sixth layer of patterned metal circuit layer; the sixth layer of patterned metal circuit layer is provided with a structure for welding BGA solder balls;

[0079] 5 layers of insulating dielectric layers between adjacent patterned metal circuit layers;

[0080] Multiple chip mounting areas located on the first patterned metal circuit layer;

[0081] A plurality of blind holes located between the patterned metal circuit layer and the insulating medium layer are used to realize the interconnecti...

Embodiment 2

[0100] Such as image 3 As shown, this embodiment provides a method for manufacturing the six-layer wiring LCP packaging substrate 1 as described in Embodiment 1, including the following steps:

[0101] S1, such as Figure 5a As shown, blind holes are laser drilled on the second double-sided copper-clad LCP substrate 153 to form third-type blind holes 143 that penetrate and connect the third patterned metal circuit layer 113 and the fourth layer patterned metal circuit layer 114, Blind hole depth-to-diameter ratio ≤ 1;

[0102] S2, such as Figure 5b As shown, the metallization of blind holes forms the third type of blind holes 143 filled with solid electroplated copper; The electroplating copper process is realized. After hole filling electroplating, the copper plating layer on the surface is thinned to form a third type of blind hole 143 filled with solid electroplated copper;

[0103] S3, such as Figure 5c As shown, the third patterned metal circuit layer 113 and the ...

Embodiment 3

[0113] As shown in FIG. 5, based on the LCP packaging substrate described in Embodiment 1-2, this embodiment provides a multi-chip system-in-package structure 61, including: the LCP packaging substrate 1 described in Embodiment 1-2, and BGA solder ball 2, chip 3, metal frame 5 and metal cover 6;

[0114] The BGA solder balls 2 are soldered to the bottom surface of the LCP packaging substrate 1, and serve as the external secondary cascade I / O interface of the multi-chip system-in-package structure 61;

[0115] Metal partitions 51 are distributed in the metal enclosure 5; the metal enclosure 5 and the metal partitions 51 are welded to the upper surface of the LCP packaging substrate 1, and the metal cover 6 is welded to the metal enclosure 5 and the metal partitions 51, between the LCP packaging substrate 1 and the metal cover plate 6, a plurality of cavity structures 7 with airtight sealing performance and electromagnetic shielding performance are formed through the metal surro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com