Airtight high-thermal-conductivity LCP packaging substrate and multi-chip system-in-package structure

A packaging substrate, high thermal conductivity technology, applied in the direction of electrical components, semiconductor devices, semiconductor/solid-state device components, etc., to achieve the effects of simple packaging, good compatibility, and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

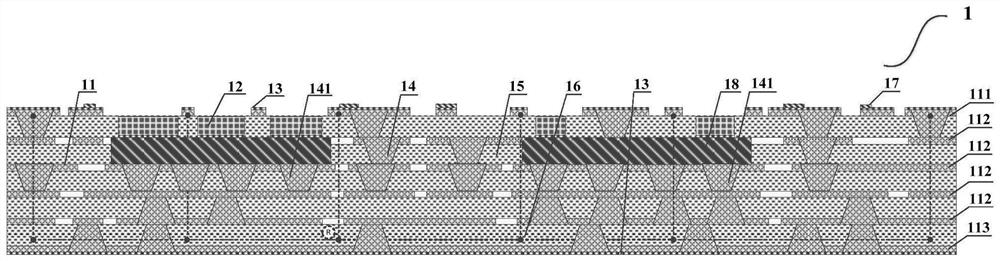

[0051] Such as figure 1 As shown, a kind of airtight high thermal conductivity LCP package substrate of the present embodiment comprises:

[0052] There are n layers of patterned metal circuit layers distributed from the surface to the bottom surface. On at least one edge of the outermost edge of the first layer of patterned metal circuit layer on the surface, solder for external secondary cascaded I / O welding of the LCP packaging substrate is distributed. disk or graphics;

[0053] N-1 layers of insulating dielectric layers located between adjacent patterned metal circuit layers;

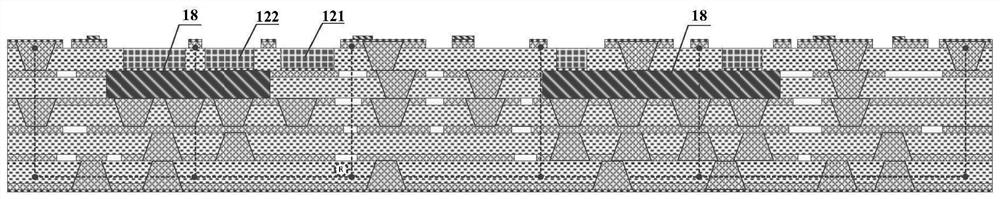

[0054] A plurality of blind grooves of the first patterned metal circuit layer with openings facing the surface in the insulating medium layer between the first patterned metal circuit layer and the second layer patterned metal circuit layer; the blind grooves include Ordinary chip mounting blind slots and high-power chip mounting blind slots;

[0055] A metal block located in the insulating med...

Embodiment 2

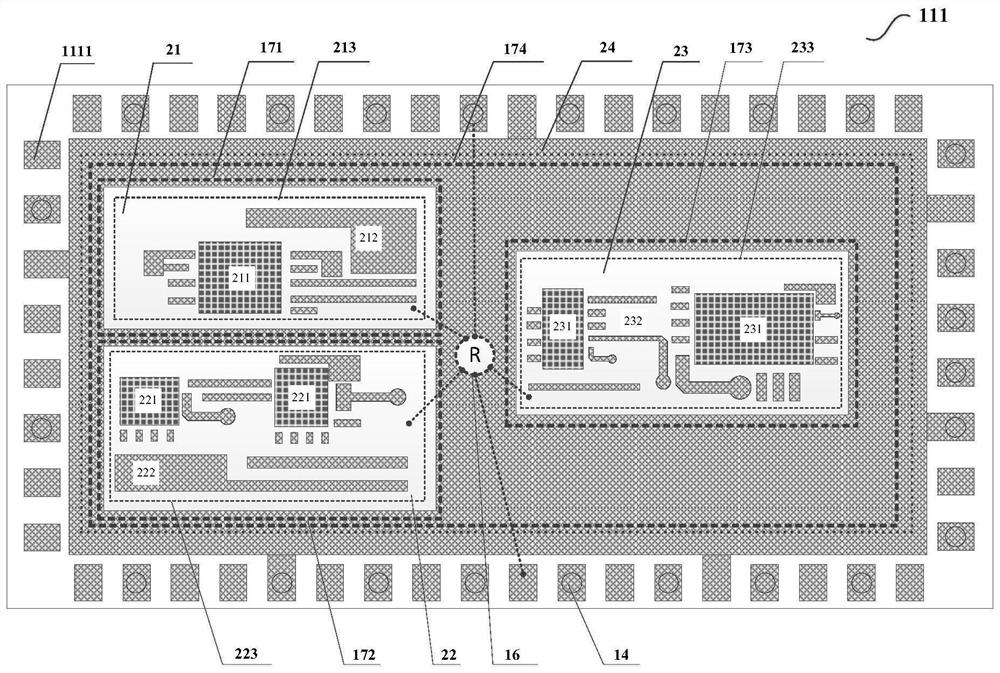

[0074] Such as Figure 5 As shown, based on the LCP packaging substrate described in Embodiment 1, this embodiment provides a multi-chip system-in-package structure 2, including: the LCP packaging substrate 1 as described in Embodiment 1, and a chip 3, and a metal frame 5 and metal cover plate 6;

[0075] The multi-chip system-in-package structure 2 is fixed on the PCB mother board by means of conductive adhesive bonding or welding, and the pads or patterns 1111 for external secondary cascading I / O welding on the LCP packaging substrate 1 are used. As the external secondary cascade I / O interface of the multi-chip system-in-package structure 61;

[0076] Metal ribs 51 are distributed in the metal surrounding frame 5; the metal surrounding frame 5 and the metal ribs 51 are welded on the upper surface of the LCP package substrate 1 and make the external secondary cascaded I / O welding pads or Figure 1111 is outside the metal frame 5, and the metal cover plate 6 is welded on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com