Airtight high-thermal-conductivity LCP packaging substrate, manufacturing method and multi-chip system-in-package structure

A packaging substrate, high thermal conductivity technology, used in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., to meet the needs of heat dissipation, high electromagnetic shielding, and high assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

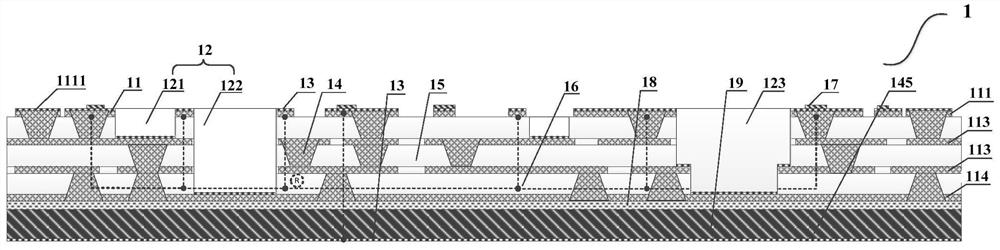

[0058] like figure 1 As shown, a kind of airtight high thermal conductivity LCP packaging substrate of this embodiment includes: any layer of LCP interconnects a multi-layer substrate, an adhesive layer and a metal back plate; the metal back plate is bonded to the LCP through an adhesive layer Arbitrary layers interconnect the bottom surface of multilayer substrates;

[0059] The LCP arbitrary layer interconnection multilayer substrate includes: n layers of patterned metal circuit layers, on at least one edge of the outermost periphery of the first layer of patterned metal circuit layers on the surface, the external secondary cascade I of the LCP packaging substrate is distributed. / O welding pads or patterns; n-1 layers of insulating dielectric layers between adjacent patterned metal circuit layers; a plurality of blind holes that are located in the insulating dielectric layer and open toward the first layer of patterned metal circuit layers Groove; a plurality of blind hole...

Embodiment 2

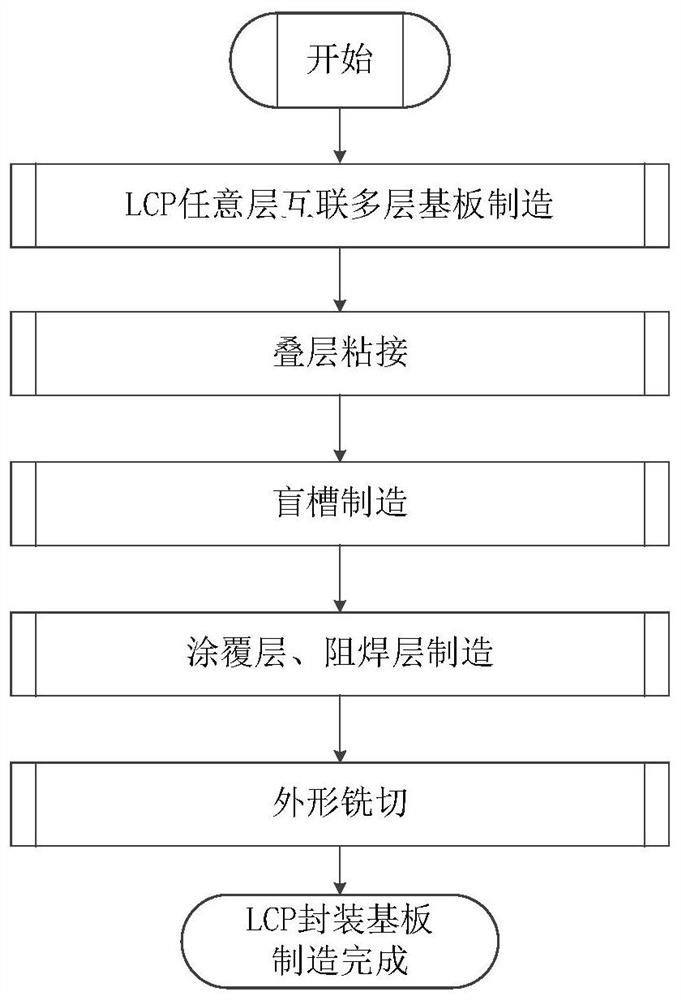

[0077] Such as image 3 As shown, this embodiment provides a method for manufacturing the airtight and high thermal conductivity LCP packaging substrate 1 as described in Embodiment 1, including the following steps:

[0078] S1, such as Figure 4a As shown, the HDI lamination process is used to manufacture LCP arbitrary layer interconnection multi-layer substrates, and the position of the blind slot is preset. The patterned metal circuit layer corresponding to the preset blind slot position does not have metal lines;

[0079] S2, take the adhesive layer 18 and the metal backplane 19, and then interconnect the multilayer substrate, the adhesive layer, and the metal backplane according to the sequence of any layer of the LCP from top to bottom, according to Figure 4b stack as shown and then bonded as Figure 4c the structure shown;

[0080] S3, such as Figure 4d As shown, use laser processing means to carry out blind slot slotting at the preset blind slot position to form ...

Embodiment 3

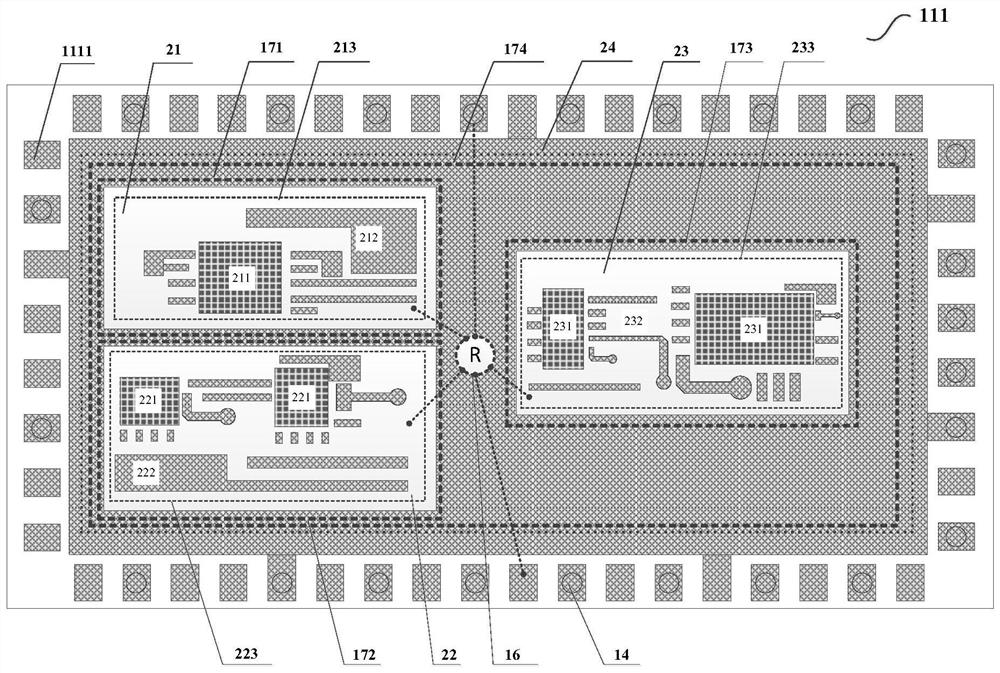

[0085] Such as Figure 5 As shown, based on the LCP packaging substrate described in Embodiment 1-2, this embodiment provides a multi-chip system-in-package structure 2, including: the LCP packaging substrate 1 as described in Embodiment 1-2, and chips 3, Metal enclosure 5 and metal cover plate 6;

[0086] The multi-chip system-in-package structure 2 is fixed on the PCB mother board by means of conductive adhesive bonding or welding, and the pads or patterns 1111 for external secondary cascading I / O welding on the LCP packaging substrate 1 are used. As the external secondary cascade I / O interface of the multi-chip system-in-package structure 2;

[0087] Metal ribs 51 are distributed in the metal surrounding frame 5; the metal surrounding frame 5 and the metal ribs 51 are welded on the upper surface of the LCP package substrate 1 and make the external secondary cascaded I / O welding pads or The figure 1111 is outside the metal frame 5, and the metal cover plate 6 is welded on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com