Rotor of centrifugal machine

A technology of centrifuges and rotors, which is applied in centrifuges and other directions, and can solve the problems of card ejection failure, damage to centrifugal turntable, reagent card falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

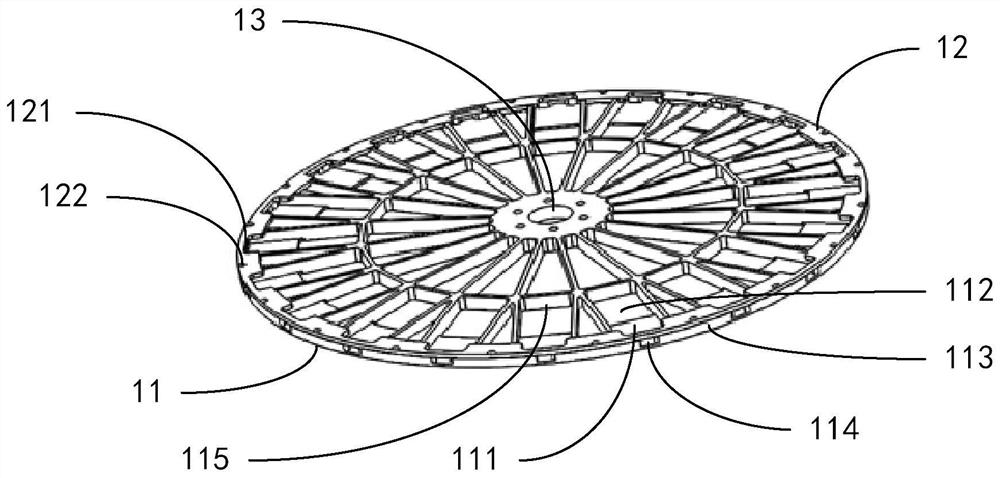

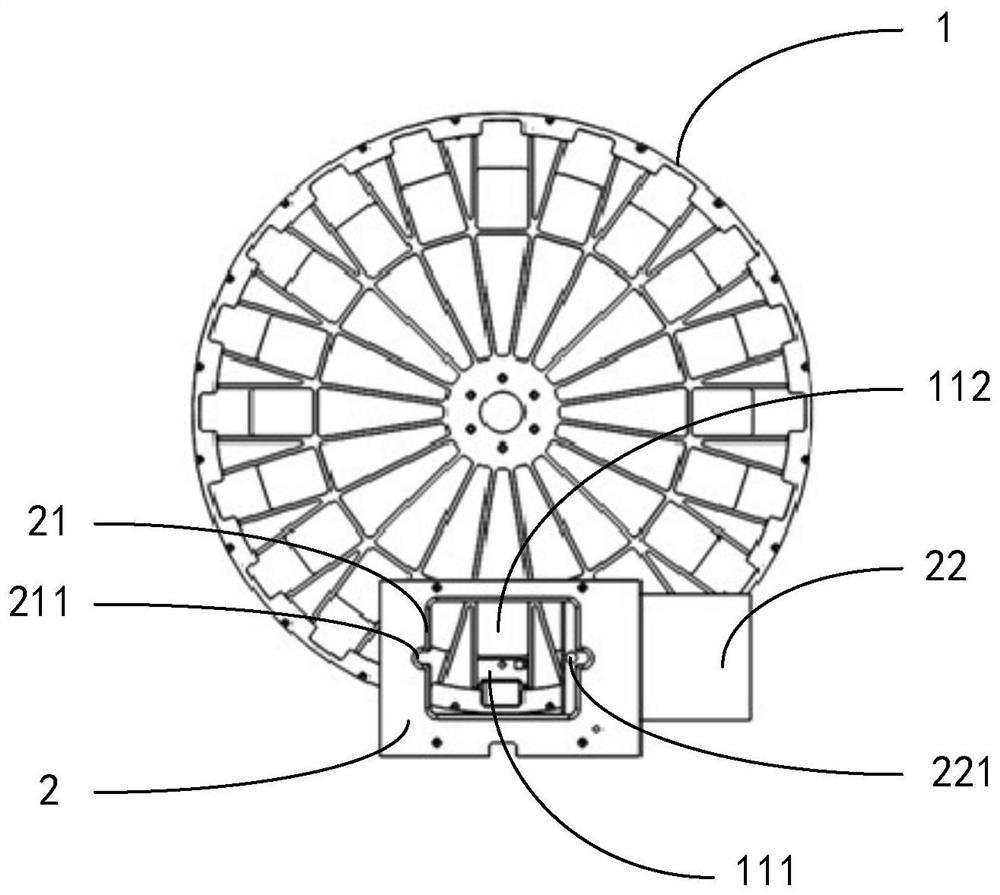

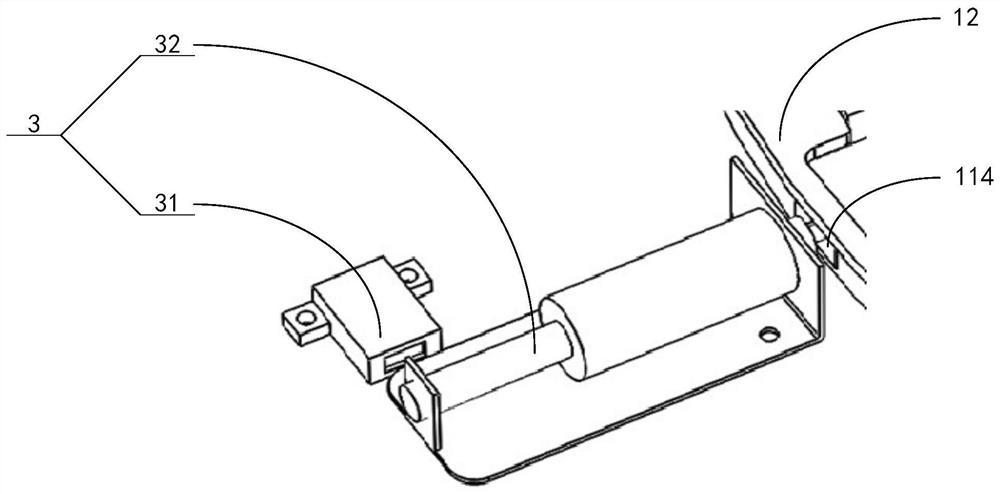

[0030] The embodiment of the present invention provides a rotor of a centrifuge. By designing a fixed stopper on the outside of the clamping position on the centrifugal turntable of the centrifuge, and setting an empty slot on the inside of the clamping position on the centrifugal turntable of the centrifuge, it is realized from the clamping position Insert the reagent card into the card position from the inside to the outside in the empty slot on the inner side and press against the stopper outside the card position. During centrifugation, the reagent card is blocked by the stopper outside the card position. At the same time, a controllable automatic The card ejection module can use the push-pull rod of the card ejection module to pop the reagent card in the card position into the empty slot from the card ejection port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com