A garbage compactor

A technology of garbage compressing and rotating plates, applied in trash cans, garbage collection, household appliances, etc., can solve problems such as occupying space, and achieve the effect of avoiding space vacancies, reducing the number of clearings, and improving space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

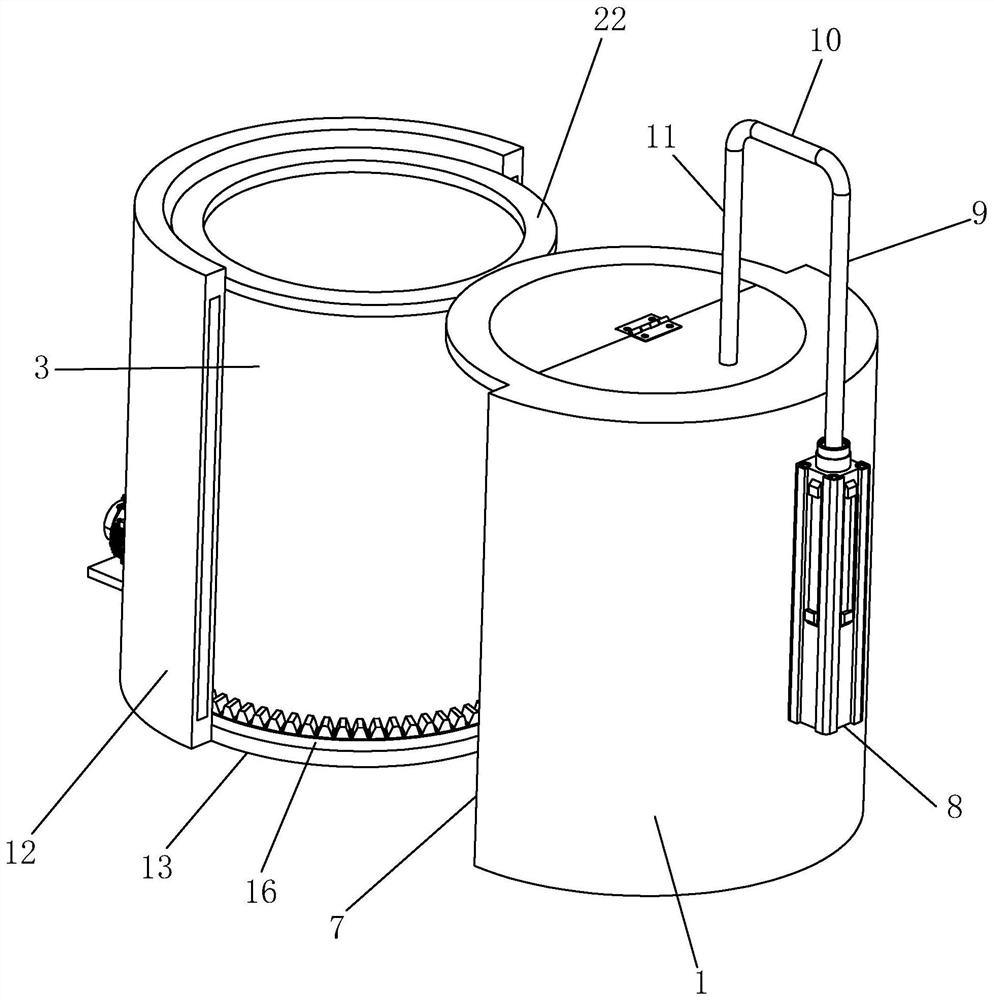

[0035] The following is attached Figure 1-6 The application is described in further detail.

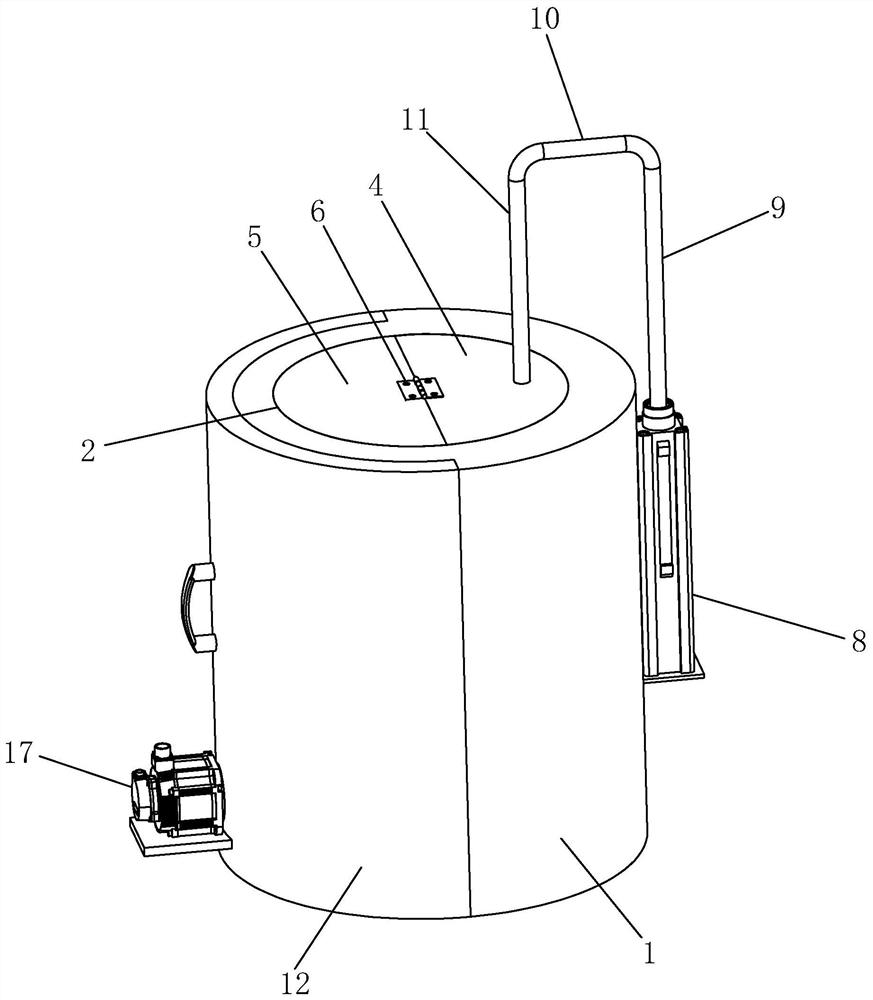

[0036] The embodiment of the present application discloses a garbage compression device. refer to figure 1 , The garbage compression device includes a housing 1, a push plate and a driving member, and the upper end surface of the housing 1 is provided with a circular feeding port 2. The push plate is flush with the feed port 2, and the shape of the push plate is the same as that of the feed port 2 and is also circular. Close the feed port 2 to prevent the odor of the garbage in the housing 1 from escaping.

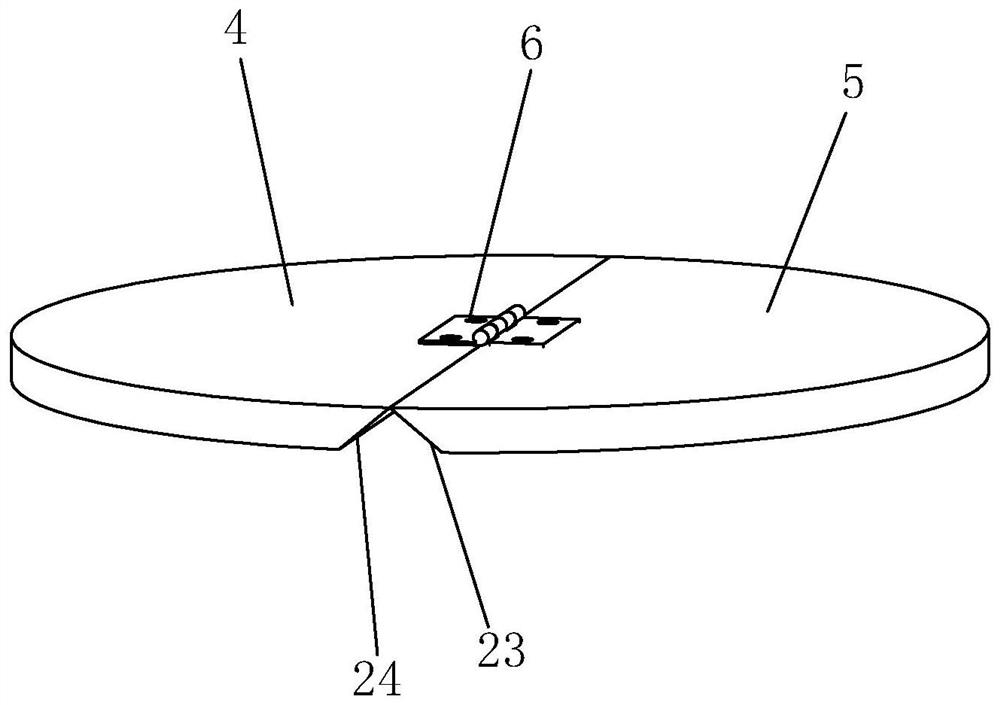

[0037] refer to figure 2 , Push plate comprises fixed plate 4 and rotating plate 5, is connected with rotating member 6 between rotating plate 5 edges and fixed plate 4 edges, and rotating member 6 allows rotating plate 5 to rotate downwards and prevents rotating plate 5 to rotate upwards. The rotating plate 5 has a natural state and a rotating state. When the rotating plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com