A feeding mechanism for sanitation garbage truck

A garbage truck and sanitation technology, which is applied in the field of sanitation vehicle accessories, can solve the problems of inability to accurately match the position of the garbage can, cumbersome and laborious operation, and low efficiency of loading garbage cans, so as to improve the convenience and efficiency of loading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

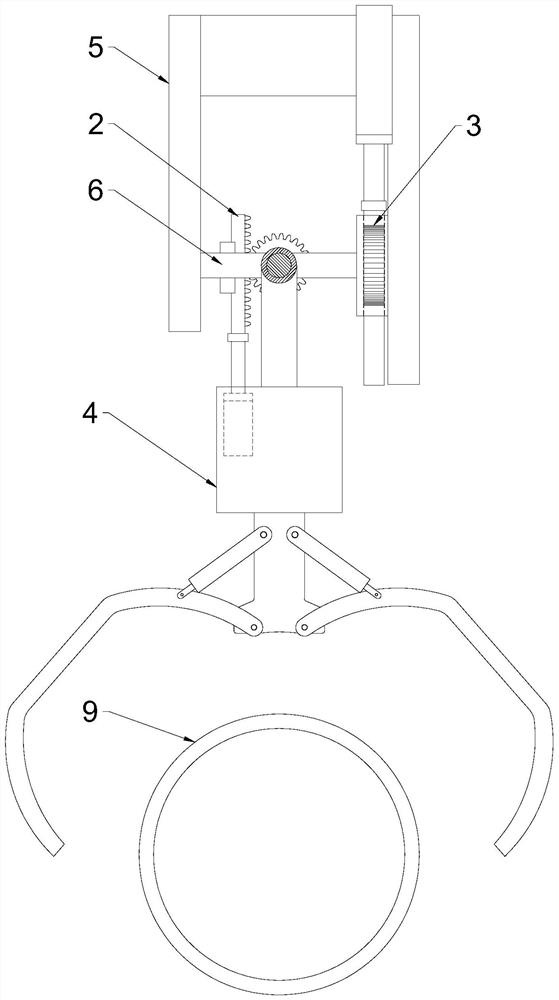

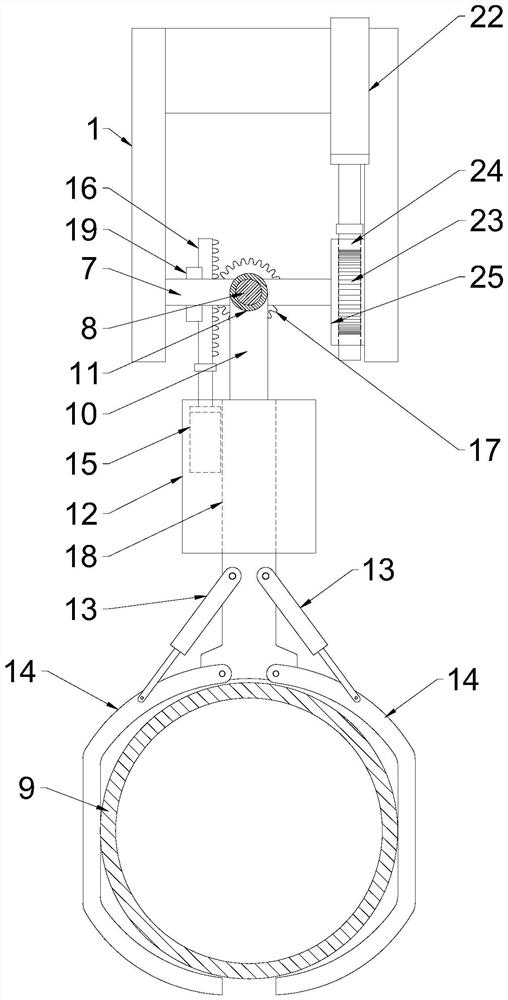

[0029] like Figure 2 to Figure 7 As shown, a feeding mechanism of an sanitation garbage truck includes a feeding frame 1 , a rotating part 2 , a turning part 3 and a clamping part 4 .

[0030] The feeding rack 1 is installed on the car body, such as figure 2 and Figure 5 As shown, the feeding rack 1 includes a rack body 5 and a cross-shaped transmission shaft 6 that is horizontally installed on the rack body 5. Bearings are installed on the left and right side frames of the rack body 5; The transverse arm 7 and the longitudinal arm 8 are circular in cross-section. The two ends of the transverse arm 7 are respectively rotatably installed in the bearings of the frame body 5. The shaft 6 drives the clamping member 4 to turn upward as a whole, so as to discharge the garbage in the trash can 9 into the truck body.

[0031] Please refer to Figure 2 to Figure 4 , the rotating member 2 is installed at the bottom of the longitudinal arm 8 of the transmission shaft 6, the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com