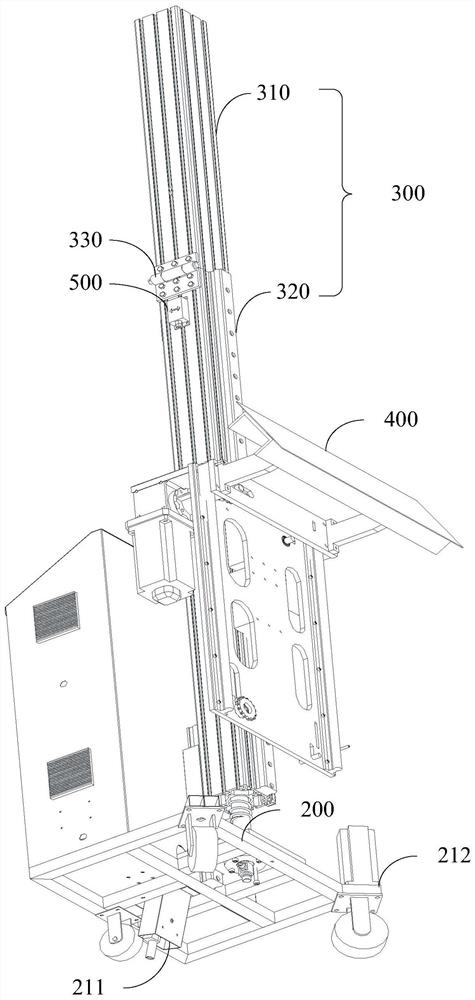

Wall plastering machine, wall plastering machine leveling method and device, readable storage medium and system

A wall plastering and leveling technology, which is applied in the control of using feedback, construction, building structure, etc., can solve the problems of large movements of the wall plastering machine, affecting the parallel state of the equipment, and shaking of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

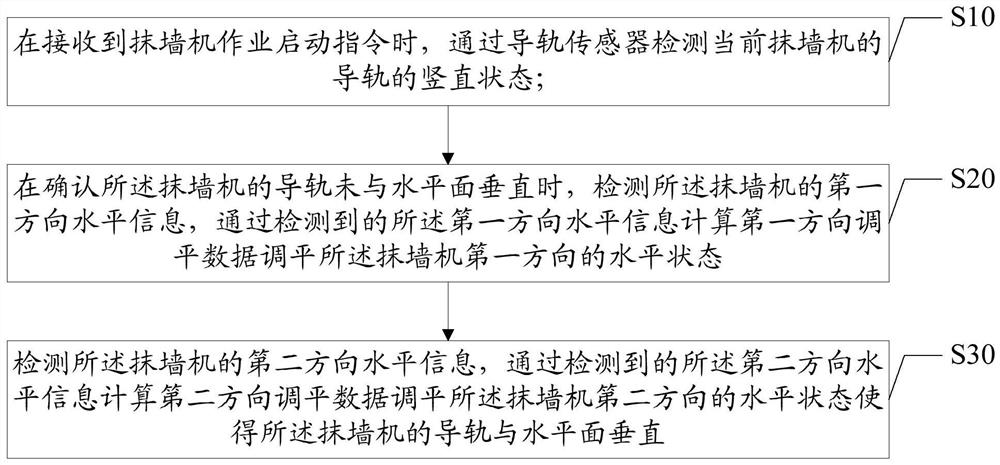

[0056] refer to figure 2 , figure 2 It is the first embodiment of the leveling method of the wall plastering machine of the present invention, and the leveling method of the wall plastering machine includes the following steps:

[0057] Step S10, when receiving the operation start command of the wall plastering machine, the vertical state of the guide rail of the current wall plastering machine is detected by the guide rail sensor;

[0058] According to the current operation requirements of the wall plastering machine, when the wall plastering machine is moved to the designated working position, the sensor installed on the guide rail detects the vertical state of the guide rail of the wall plastering machine at the current working position of the wall plastering machine, wherein the The vertical state of the guide rail is defined as the vertical state of the guide rail and the horizontal plane, that is, to confirm whether the guide rail of the wall plastering machine is per...

no. 2 example

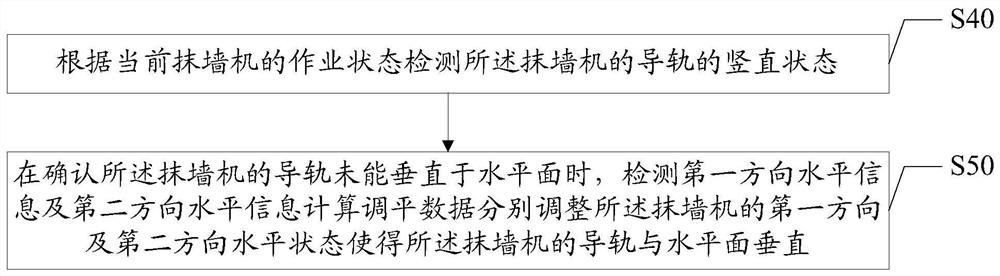

[0073] Further, you can also refer to image 3 , image 3 It is the second embodiment of the leveling method of the wall plastering machine of the present invention, and the leveling method of the wall plastering machine further includes:

[0074] Step S40, detecting the vertical state of the guide rail of the wall plastering machine according to the current working state of the wall plastering machine;

[0075] Step S50, when it is confirmed that the guide rail of the wall plastering machine is not perpendicular to the horizontal plane, detect the horizontal information of the first direction and the horizontal information of the second direction to calculate the leveling data and adjust the first direction and the second direction of the wall plastering machine respectively The horizontal state makes the guide rail of the wall plastering machine perpendicular to the horizontal plane.

[0076]In this embodiment, when it is confirmed that the current wall plastering machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com