Locking device

A locking device and a pair of technology, applied in the field of locking technology on storage boxes, can solve the problems of inconvenient disassembly, small contact area, and large force, and achieve easy manufacturing and disassembly, not easy to wear, and effective small force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015]The present invention will be further described in connection with the accompanying drawings and examples:

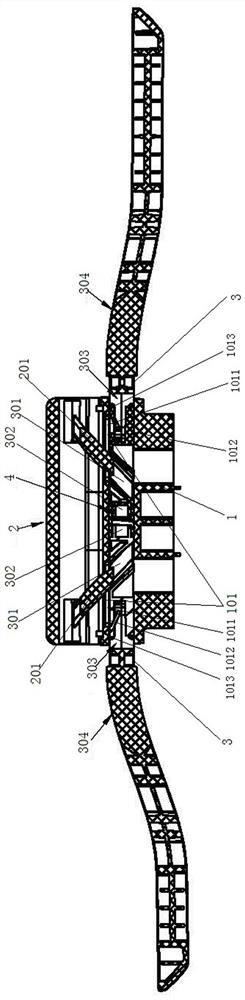

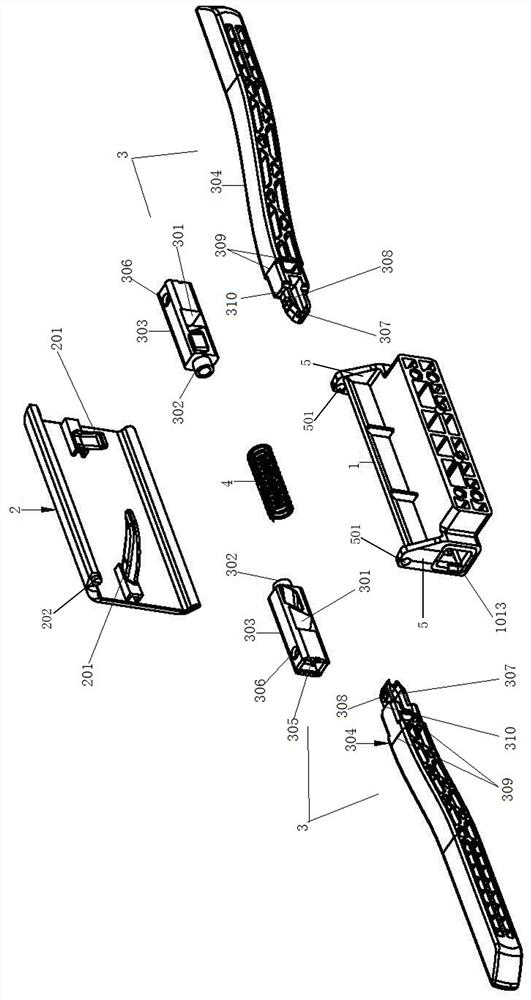

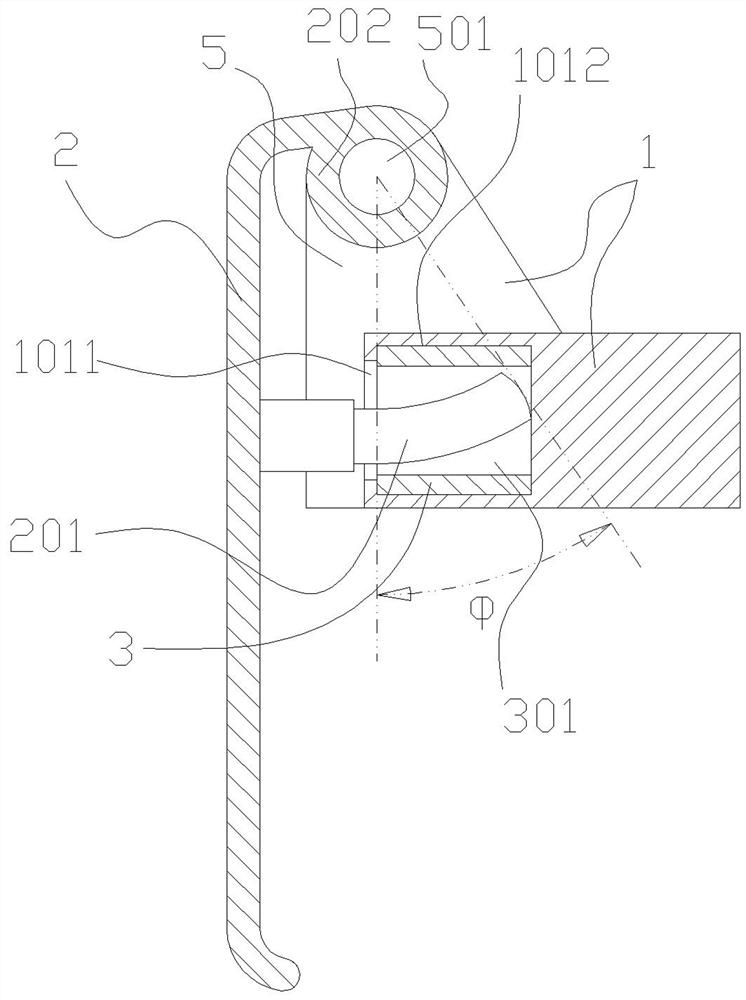

[0016]Such asfigure 1 As shown, the present invention includes a support frame 1, a handle 2 disposed on the support frame 1, a pair of slide pin 3, the spring ring 4, which is particularly provided in both sides of the support frame 1, and a guide structure 101, a pair The sliding pin 3 slides on the guiding structure 101 on both sides of the support frame 1, and a hole-like chute 301 is provided on the slide pin 3, and the chute 301 is obliquely towed toward the middle portion of the support frame 1, the corresponding slant groove 301. The handle 2 is provided with a curved drive rod 201, the free end of the drive rod 201 to the middle portion of the handle 2, and the spring ring 4 is disposed between a pair of sliding pins 3.

[0017]A handle joint 5 is provided on both sides of the support frame 1, and the shaft hole 202 on the upper edge of the handle 2 is rotated on the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap