Angle-adjustable hydraulic jack opposite jacking test device

A technology of hydraulic jack and test device, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc. Working conditions and other problems to achieve the effect of accurate use of performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

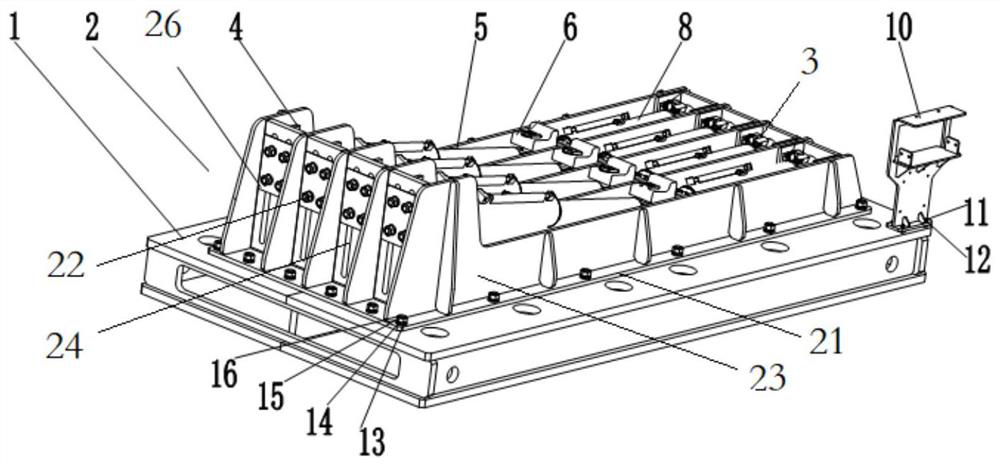

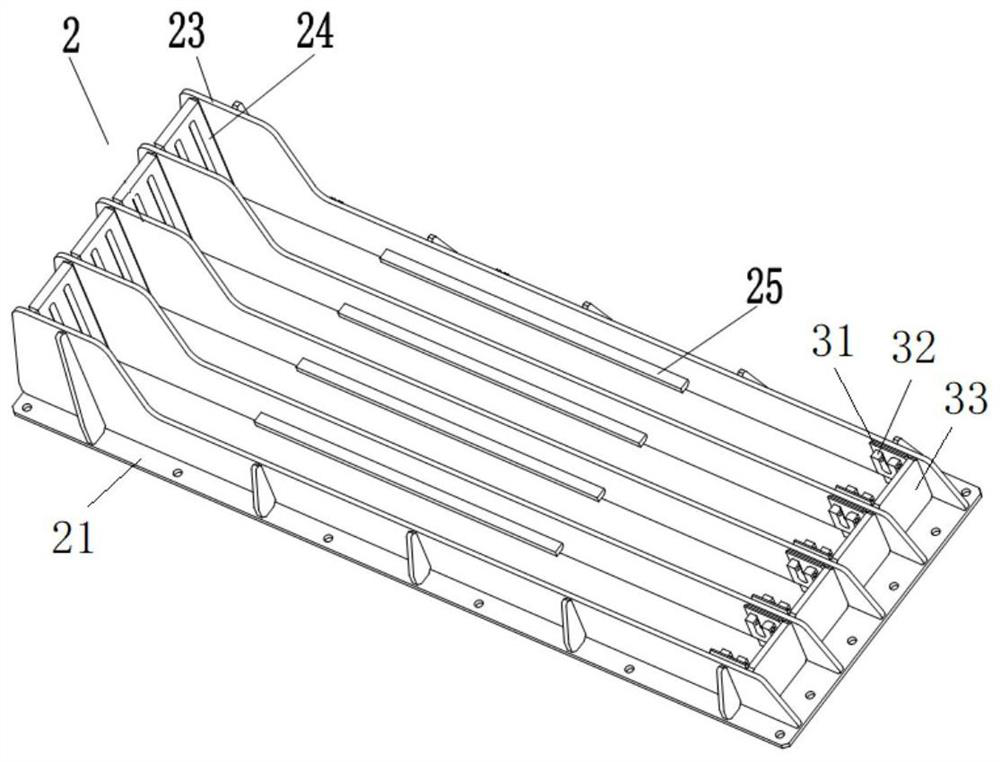

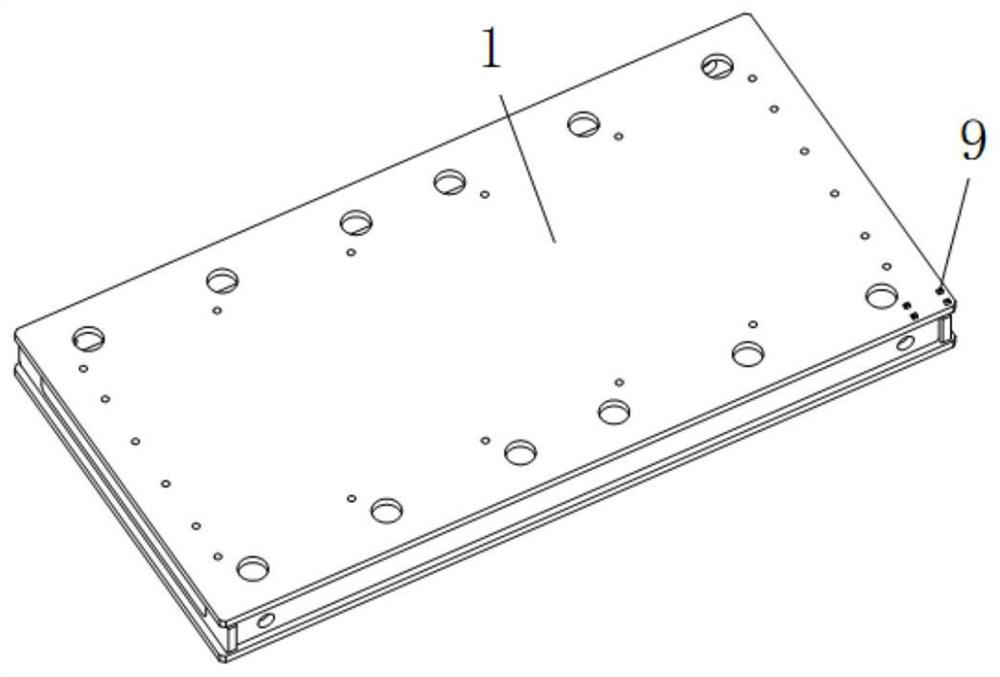

[0025] see figure 1 , figure 2 and image 3 , an angle-adjustable hydraulic jack jacking test device provided by an embodiment of the present invention includes a base 2, the base 2 includes a bottom plate 21, and at least two main ribs of the base that are vertically welded on the bottom plate 21 are parallel to each other 23. A U-shaped orifice plate 24 perpendicular to the bottom plate 21 is welded between one end of every two main ribs 23 of the base, and a jack fixing seat is fixed between the other ends of each two main ribs 23 of the base 3. The middle part of every two base main ribs 23 is provided with a slider 6 that can slide back and forth on the chute formed between the two base main ribs 23, and the U-shaped orifice between the two base main ribs 23 24 side walls are provided with the slide seat 4 that can move up and down on the U-shaped orifice 24 side walls. The cylinder bottom end of the test jack 5 is hinged with the slide seat 4, and the piston rod end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com