Electronic cigarette atomization core and atomizer

A technology of electronic cigarettes and atomizers, which is applied in tobacco and other fields, can solve the problems of condensation of large particles of e-liquid droplets, inhalation of e-liquid, and easy accumulation, so as to achieve the effect of improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

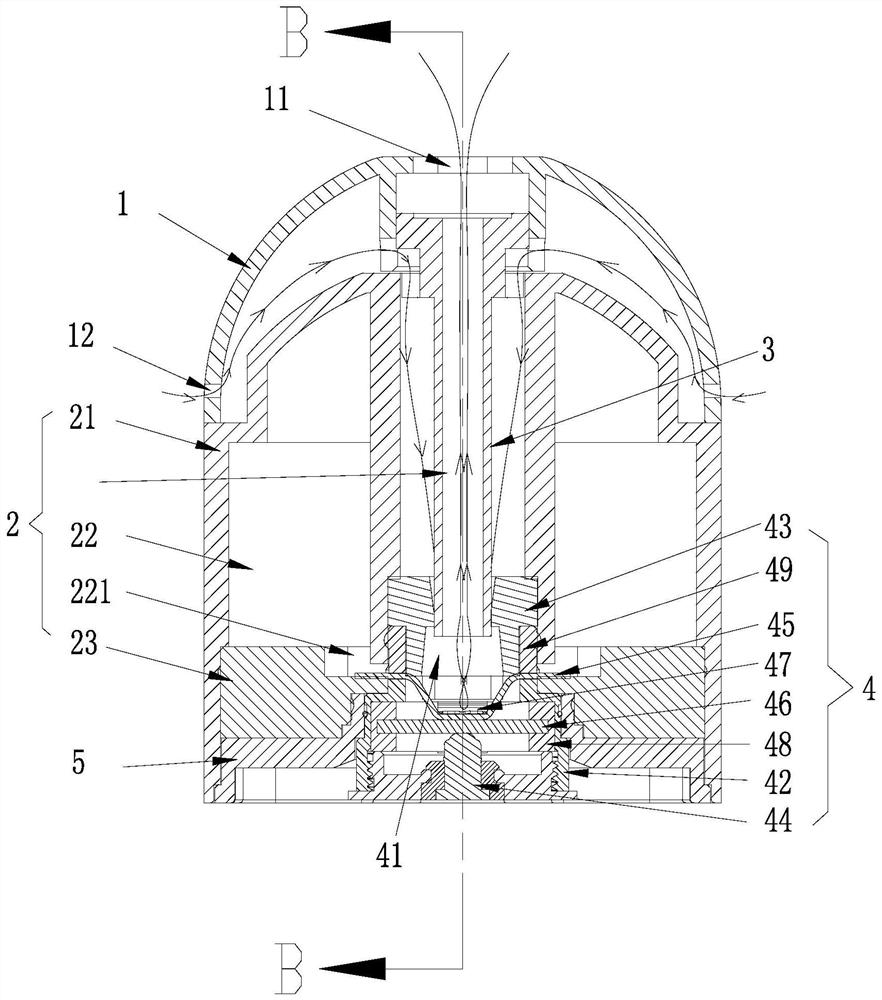

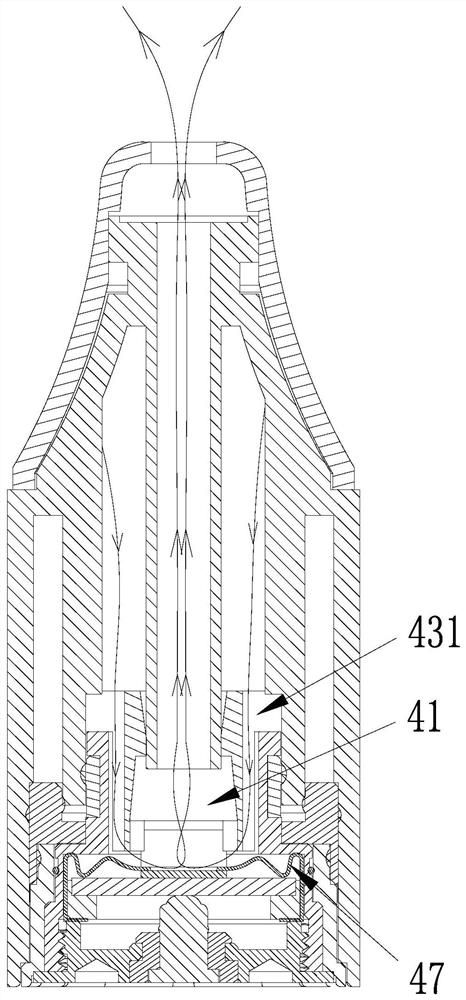

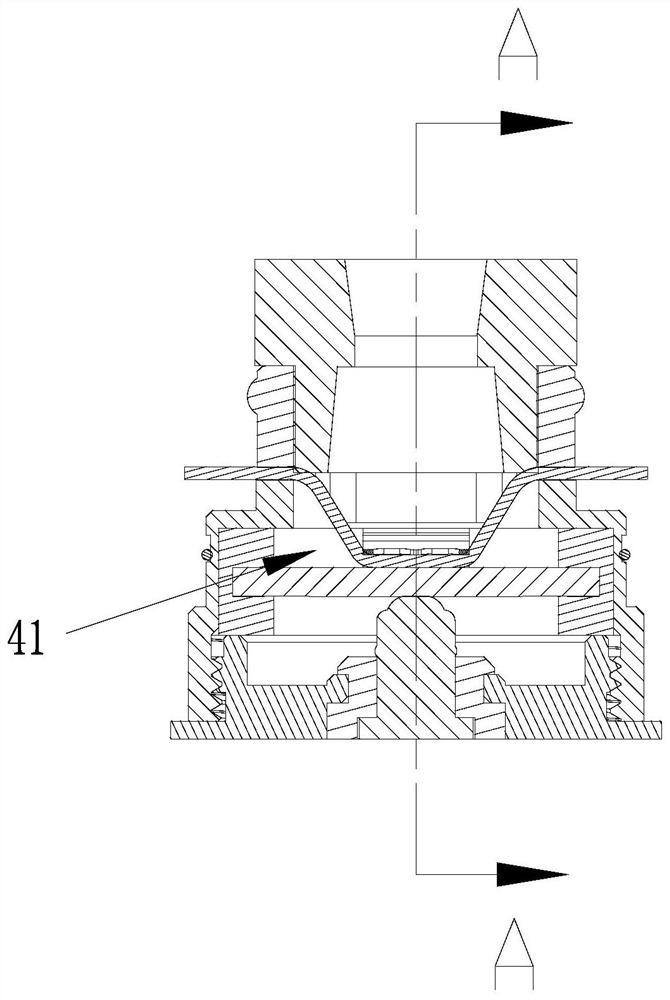

[0036] Such as Figure 1-Figure 9 As shown, an embodiment of the electronic cigarette atomizer of the present invention includes a suction nozzle device 1 and an oil tank device 2 connected to each other. The suction nozzle device 1 is provided with a suction nozzle 11 and an air inlet 12, and the middle of the oil tank device 2 is provided with an air outlet pipe. 3 and the atomizing core 4, the atomizing chamber 41 is set in the atomizing core 4, the top of the air outlet pipe 3 communicates with the suction nozzle 11, and the bottom of the air outlet pipe 3 extends into the atomizing chamber 41, so that the atomizing chamber 41, the air outlet pipe The inner cavity of 3 and the suction nozzle 11 are connected to form a smoke discharge channel, and the air inlet 12, the outer periphery of the air outlet pipe 3 and the atomization chamber 41 are connected to form an external air intake channel.

[0037] The oil tank device 2 includes an oil tank housing 21 and an oil tank bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com