Self-centering constant-velocity universal joint assembly

A constant velocity universal joint and self-centering technology, which is applied in the direction of elastic couplings, mechanical equipment, couplings, etc., can solve the problems of small torque, large rotation angle, etc. The effect of increasing the angle and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

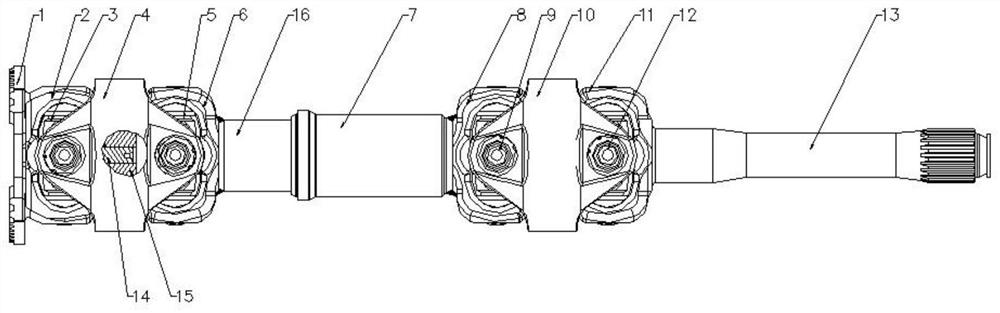

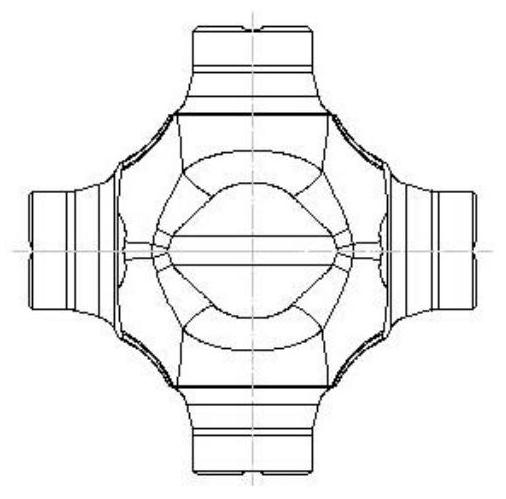

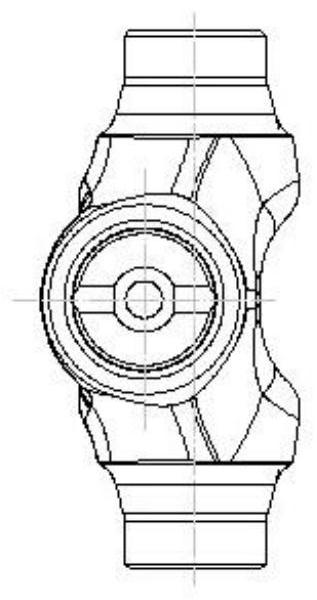

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

[0027] refer to Figure 1-Figure 4 , the self-centering constant velocity universal joint assembly of the present invention includes a first column 14, a second column, a frame flange flange, a spline sleeve assembly 16, a protective sleeve assembly 7, and an outer half shaft 13 , the first outer casing 4, the second outer casing 10, the first cross shaft 3, the second cross shaft 5, the third cross shaft 9, the fourth cross shaft 12, the first frame fork 6, the second frame fork 8 and the third frame Fork 11; wherein, the frame-shaped flange flange includes flange 1 and the fourth frame fork 2, the first frame fork 6, the second frame fork 8, the third frame fork 11 and the fourth frame fork 2 are all frame-shaped structures , the front of the frame structure is provided with through holes, the upper and lower end faces of the frame structure are provided with first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com