Closed LED lamp strip made of light-transmitting adhesive film and manufacturing method of closed LED lamp strip

A technology of LED light strips and manufacturing methods, which is applied in the field of circuit boards, and can solve the problems of low production efficiency, high material cost, and large amount of glue used in a single operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below by taking preferred embodiments as examples.

[0029] However, those skilled in the art should understand that the following descriptions are only examples and descriptions of some preferred implementations, and do not have any limitations on the claims of the present invention.

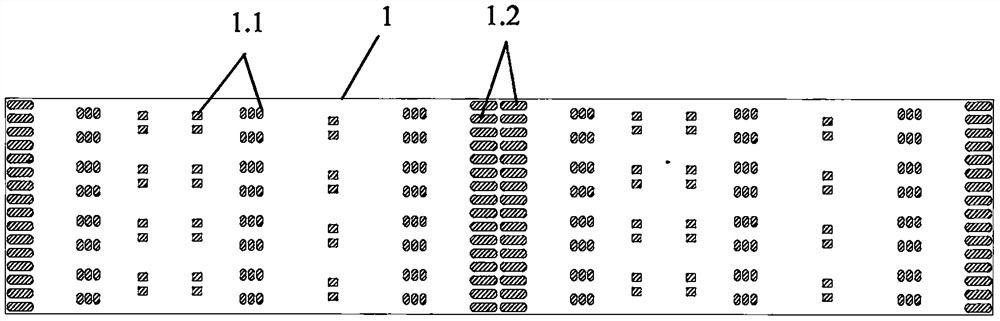

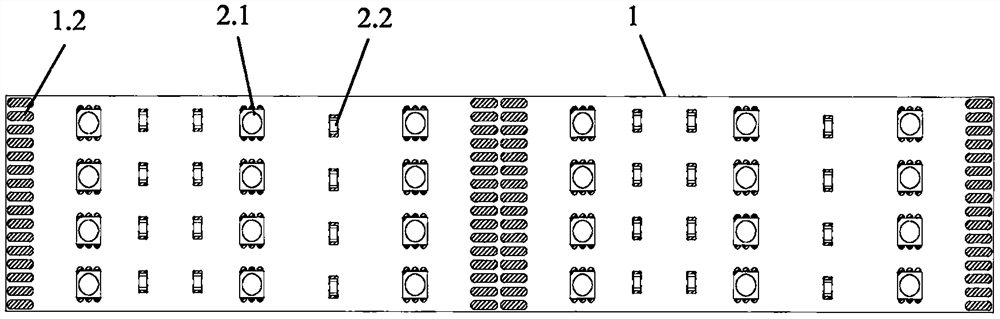

[0030] Using the traditional circuit board manufacturing process, the flexible copper-clad laminate is screen-printed with circuit resist ink, baked and cured, etched, stripped, screen-printed front ink solder resist 1.3, exposed component pad 1.1 and metal connection point 1.2, baked, characters , baking and curing, OSP anti-oxidation surface treatment and other processes are made into LED strip circuit boards 1, (such as figure 1 , Figure 9 shown), wherein, the strip light circuit board 1 shown in Fig. 1 is a single-sided light strip circuit board 1a, or a double-sided light strip circuit board 1b.

[0031] Or the double-sided flexib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com