Sliding support monitoring device and method

A sliding bearing, monitoring device technology, applied in the direction of measuring devices, electrical devices, bridge parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

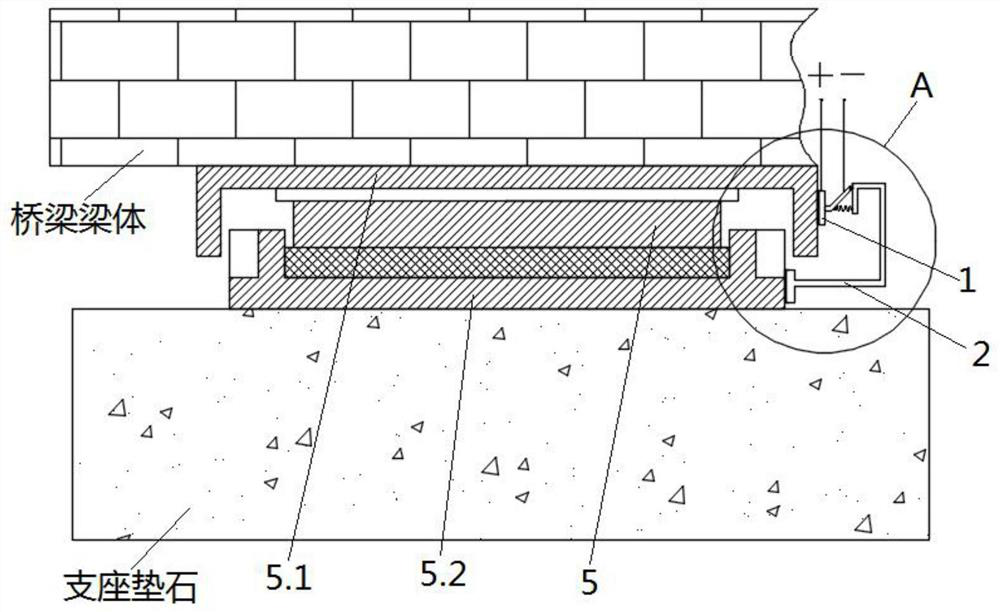

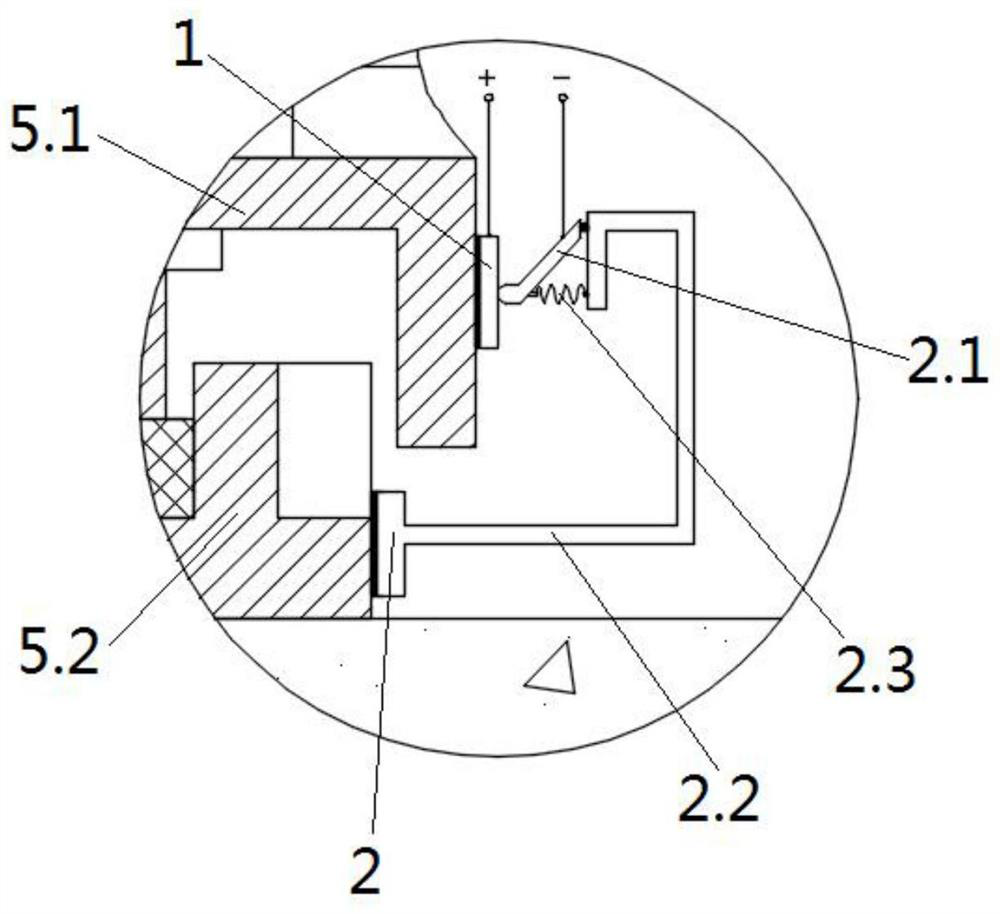

[0036] see Figure 1 to Figure 3 , a sliding bearing monitoring device and method, this embodiment is applied to the monitoring of the sliding state of the sliding bearing 5, the sliding bearing 5 is a one-way sliding bridge basin rubber bearing.

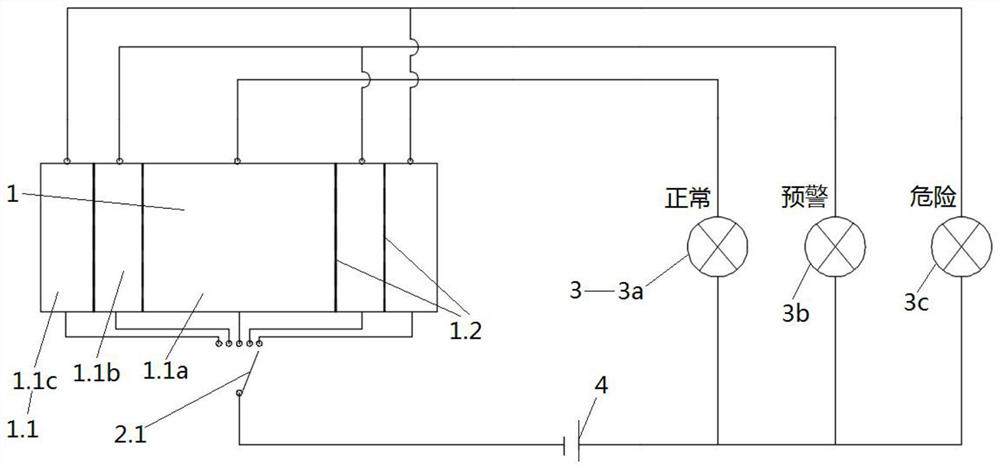

[0037] A sliding support monitoring device, comprising a conductive unit 1 and a conductive support 2, the conductive unit 1 and the conductive support 2 are respectively arranged on two relatively sliding support plates of the sliding support 5; the conductive unit 1 includes multiple A conductive block 1.1 arranged along the sliding direction of the sliding support 5, adjacent conductive blocks 1.1 are separated by an insulating member 1.2; the conductive support 2 includes a conductive contact rod 2.1, and the conductive contact rod 2.1 is connected to one of the conductive blocks. 1.1 Contact conduction; each conductive block 1.1 is connected to the conductive contact rod 2.1 through a connecting line, and each connecting line i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com