Controlling and adjusting device for printing range of three-dimensional material additive printer

A technology for controlling adjustment and printing range, applied in the direction of additive processing, processing drive device, etc., which can solve the problems of poor control of printing range and reduced use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

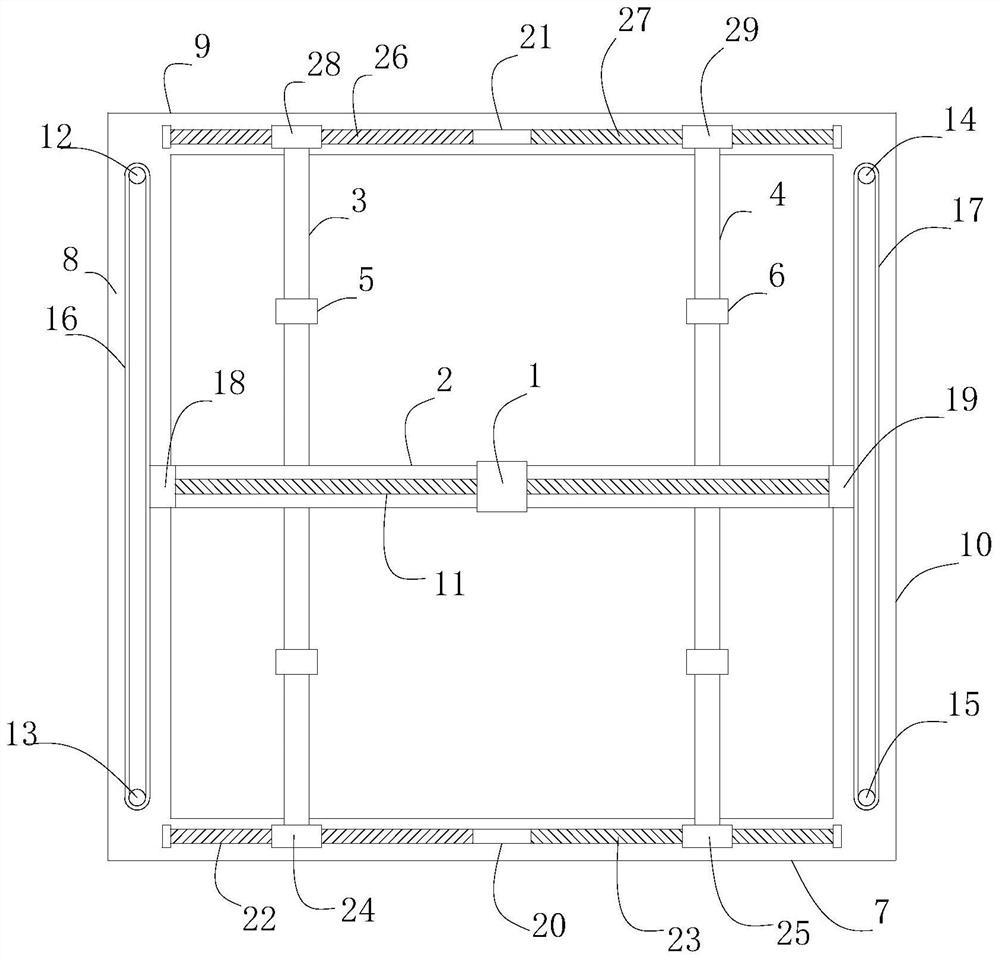

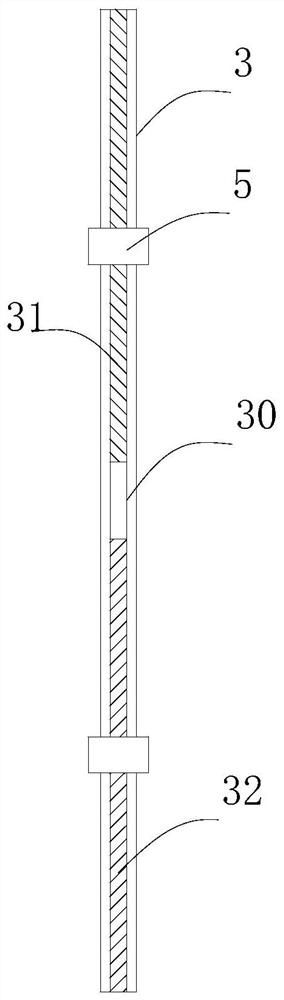

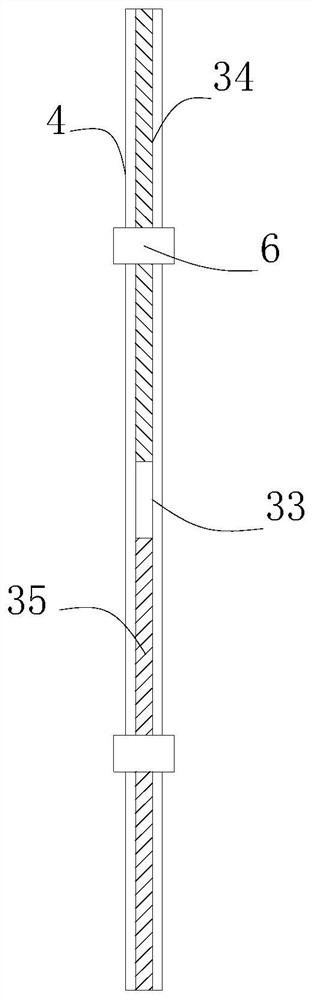

[0018] refer to Figure 1-Figure 3 , the present invention proposes a printing range control and adjustment device for a three-dimensional additive printer, including a print head mounting seat 1 and a control and adjustment mechanism; the control and adjustment mechanism includes a first moving rod 2, a second moving rod 3, a third moving rod 4, a mounting frame, a first drive member, a second drive member, a third drive member, a fourth drive member and a fifth drive member; wherein:

[0019] The mounting bracket includes a first crossbar 7, a second crossbar 8, a first longitudinal bar 9 and a second longitudinal bar 10, the first crossbar 7, the first longitudinal bar 9, the second crossbar 8, and the second longitudinal bar 10 End vertical connections in turn.

[0020] The first moving rod 2 is horizontally arranged and its two ends are respectively connected with the first longitudinal rod 9 and the second longitudinal rod 10 in sliding fit, the second moving rod 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com