Photoelectric composite submarine cable pressure-resistant waterproof joint

A technology of photoelectric composite and waterproof joints, applied in the direction of cable terminals, etc., to achieve good sealing performance, meet fast connection, and avoid accidental breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

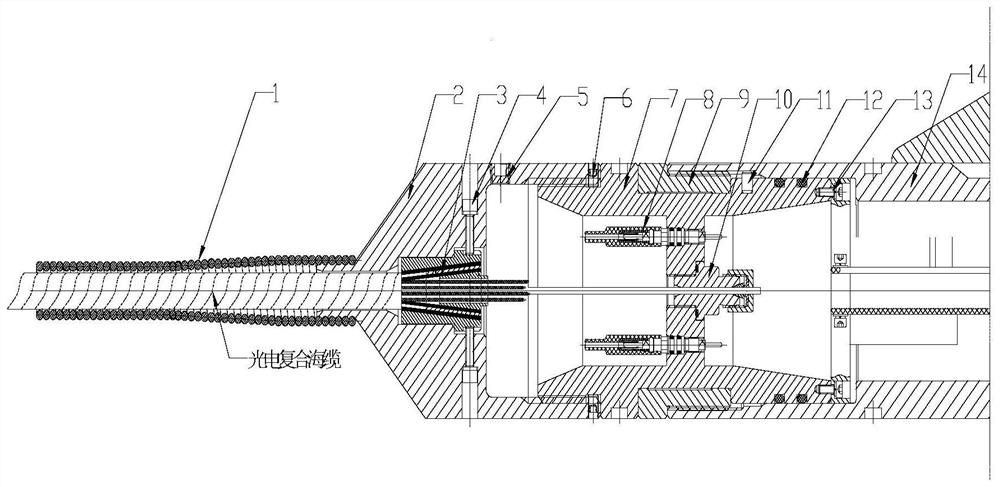

[0022] Below, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as figure 1 As shown, a photoelectric composite submarine cable pressure-resistant waterproof joint includes a spring 1, a joint body 2, a taper sleeve 3, a grease injection hole 5, a first fixing member 6, an adapter 7, a power supply connector 8, a spiral ring 9, The ferrule 10 and the second fixing piece 13, the spring 1 is fixedly arranged on the outside of the joint body 2, the spring 1 can be connected with the joint body 2 through the thread on the outside of the joint body 2, and the spring 1 is fixed along the axial direction of the joint body 2 On the outer side of the joint body 2, the spring 1 is sleeved on the photoelectric composite submarine cable to protect the photoelectric composite submarine cable so that the photoelectric composite submarine cable will not be bent and damaged. The photoelectric composite submar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com