A splicing device for CNC machining of square optical elements

An optical element and splicing device technology, applied in optical elements, optics, optical surface grinders, etc., can solve the problems of reducing the stability of the polishing process, affecting the stability of the polishing process, and the loss of polishing liquid, so as to improve the polishing stability and splicing. The effect of low precision requirements and convenient use

Active Publication Date: 2022-06-03

LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

View PDF15 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] CNC polishing usually uses cerium oxide polishing fluid to achieve high-precision and ultra-smooth surface processing of optical components, but due to its non-immersion contact polishing characteristics, a large amount of heat generated by the friction between the polishing tool and the surface of the optical component during processing It will cause the local temperature to rise, aggravate the aging speed of the polishing tool, and affect the stability of the polishing process

In addition, under the joint action of the polishing tool rotation and feed movement, the polishing liquid is seriously lost in the corner area of the component, making the concentration of the polishing liquid on the surface of the component unevenly distributed, which further reduces the stability of the polishing process and affects the optical components. Final machining accuracy and machining efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

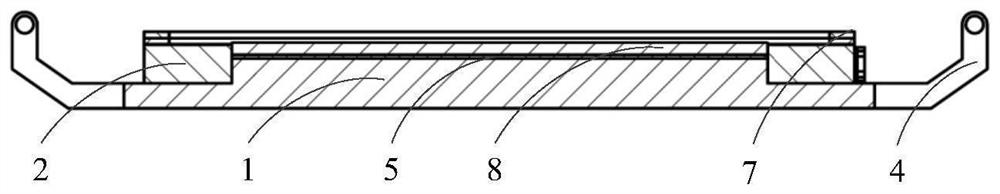

[0028] The area of the silicone pad 5 is equal to the area of the upper boss 11, and the thickness is about 1 mm. The area of tarpaulin 6 is significantly larger than that of the upper boss

[0035] The foregoing description of the disclosed embodiments enables those skilled in the art to make or use the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

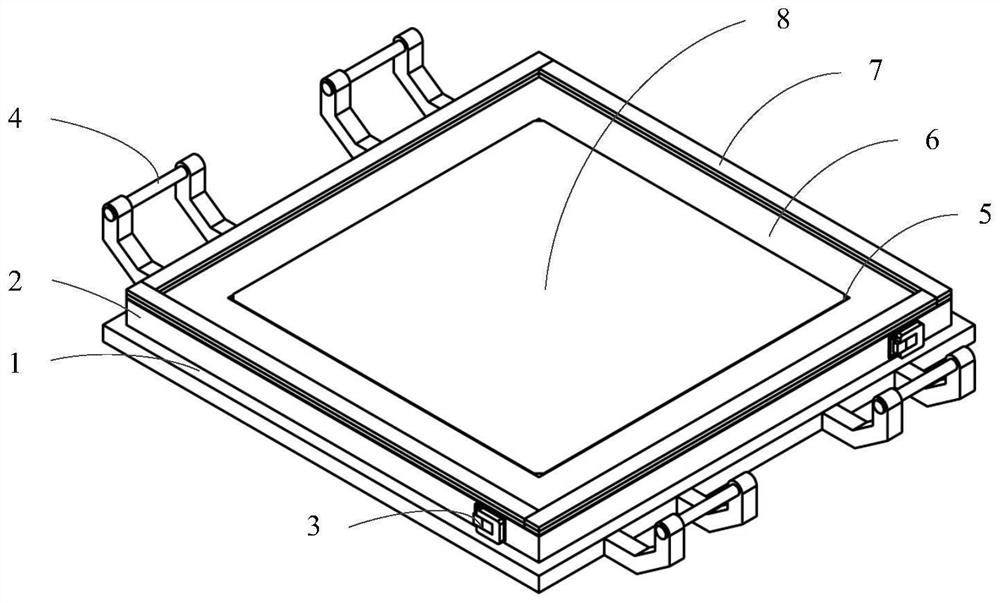

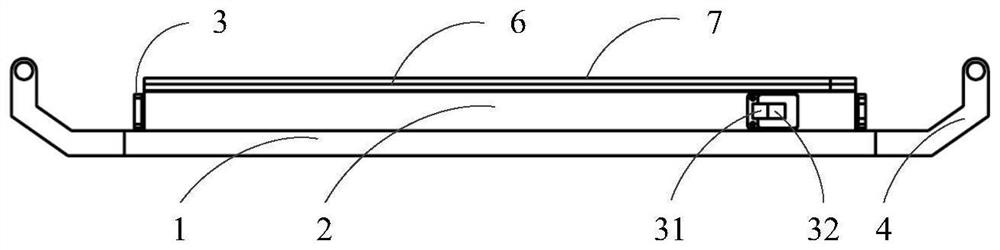

The invention discloses a splicing device for numerically controlled processing of square optical elements, which comprises a square support plate, which is a boss structure, including an upper boss and a lower boss, and the cross-sectional area of the lower boss in the horizontal direction is larger than The upper boss, the area of the upper boss is the same as the optical element to be processed; the upper boss is also provided with a silicone pad and a waterproof cloth in turn; when in use, the optical element to be processed is arranged on the waterproof cloth on; it also includes four splicing blocks, which are connected to each other and arranged above the lower boss for clamping the optical element to be processed on the upper boss, the upper of the optical element to be processed The surface is slightly higher than the upper surface of each splicing block, and several magnetic strips for fixing the waterproof cloth are arranged on the outside of the top surface of each splicing block. The above-mentioned splicing device has two functions of component clamping and polishing liquid storage at the same time, which realizes immersion polishing of components and improves the polishing stability of components.

Description

A splicing device for CNC machining of square optical components technical field The present invention relates to the technical field of optical processing, particularly a kind of splicing for the numerical control processing of square optical elements device. Background technique With the development of high-power laser devices, telescope systems, aerospace and ultraviolet lithography and other fields, the The number of demand for scientific components is increasing, and the requirements for component processing accuracy and processing efficiency are also getting higher and higher. Gadget CNC The polishing technology precisely controls the rotational speed of the polishing tool, the processing path and the processing points of the polishing tool on the surface of the component through the computer Compared with full-aperture polishing techniques such as ring polishing, it can achieve a deterministic increase in the surface material of optical components. It is th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24B13/00B24B13/005

CPCB24B13/00B24B13/0055

Inventor 黄金勇高胥华蔡超王刚谢磊赵恒胡庆何祥马平鄢定尧李瑞洁

Owner LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com