High-precision control method for flexible wire transmission surgical instrument of minimally invasive surgical robot

A technique of surgical instruments and minimally invasive surgery, which is applied in the field of medical robots, can solve the problems of rough operation, limited control precision, and inconvenient use, and achieve the effects of high accuracy, improved control precision, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

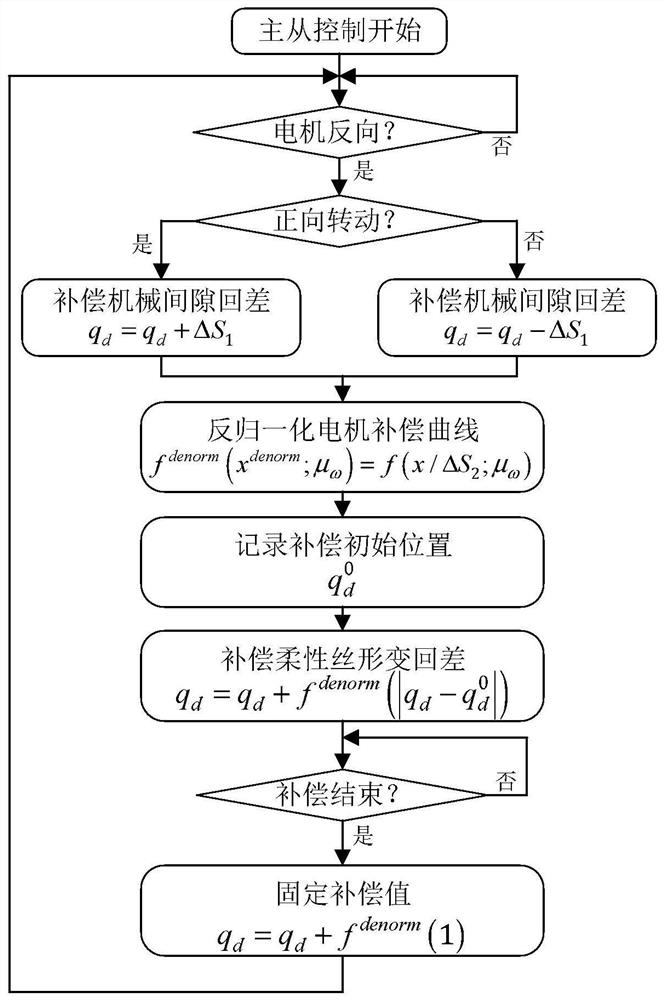

[0055] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a method for high-precision control of a minimally invasive surgical robot flexible wire-driven surgical instrument described in this embodiment, the specific steps are as follows:

[0056] Step 1. The minimally invasive surgical robot system starts master-slave control, and judges whether the actuating motor moves in the reverse direction in each control cycle;

[0057] Step 2: After actuating the motor to move in the reverse direction, judge the direction of the motor after the reverse movement, and if it turns in the forward direction, set the target position of the motor q d

[0058] q d =q d +ΔS 1 (1)

[0059] Using the motor target position q d To compensate the backlash of the mechanical clearance;

[0060] If the rotation is reversed, let the motor target position q d

[0061] q d =q d -ΔS 1 (2)

[0062] Using the motor target position q d To compensate the backlash...

specific Embodiment approach 2

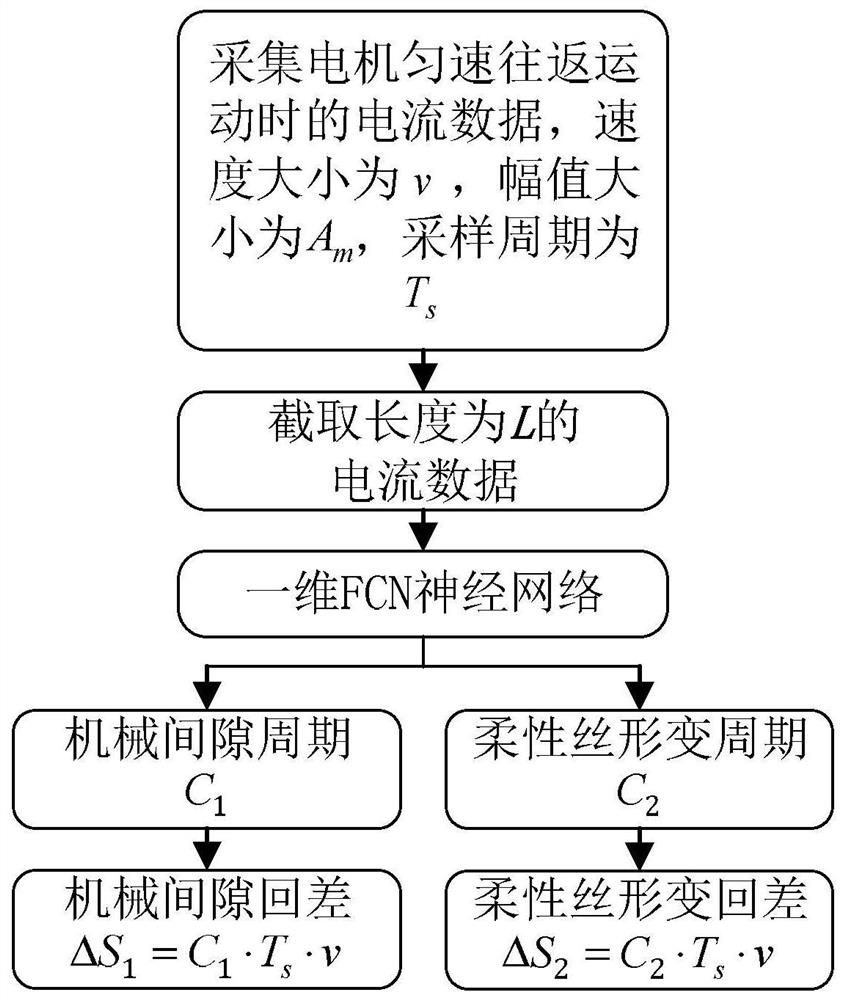

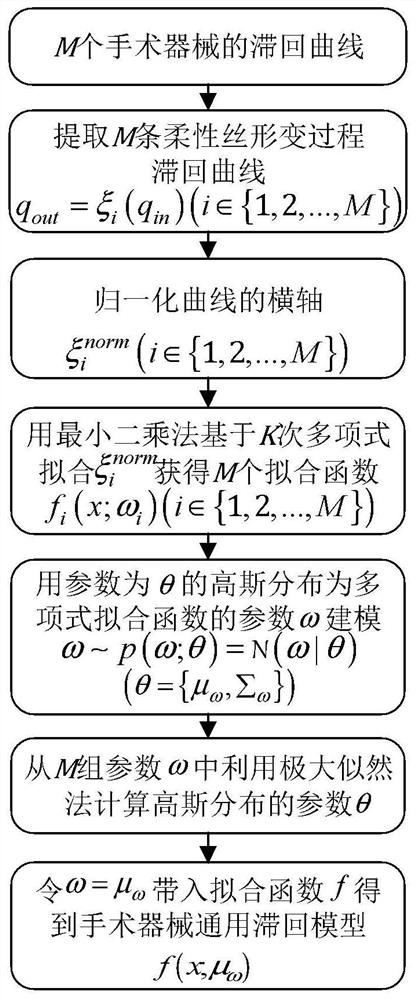

[0073] Specific implementation mode two: combination figure 2 Describe this embodiment, this embodiment is a further limitation on the control method described in the first specific embodiment, a minimally invasive surgical robot flexible wire transmission surgical instrument high-precision control method described in this embodiment, the steps described The mechanical gap hysteresis ΔS of the surgical instrument in the second 1 The calculation method is as follows:

[0074] Step 21. Before the main control starts, make the actuating motor move back and forth at a constant speed v, with an amplitude of A m , the sampling period is T s , to collect the current data of the actuating motor when it moves back and forth at a uniform speed;

[0075] Step 22, intercept the current data with a length L from the current data, and use it as the input of the one-dimensional FCN neural network;

[0076] Step two and three, the one-dimensional FCN neural network uses the current data ...

specific Embodiment approach 3

[0081] Specific implementation mode three: combination figure 2 Describe this embodiment, this embodiment is a further limitation on the control method described in the first specific embodiment, a minimally invasive surgical robot flexible wire transmission surgical instrument high-precision control method described in this embodiment, the steps described The hysteresis difference ΔS of the flexible filament of the surgical instrument in the third 2 The calculation scheme of is as follows: Before the master control starts, let the actuating motor move back and forth at a constant speed v with an amplitude of A m , the sampling period is T s , collect the current data of the actuating motor when it moves back and forth at a constant speed; intercept the current data of length L from the current data, and use it as the input of the one-dimensional FCN neural network; the one-dimensional FCN neural network uses the current data of length L to calculate the flexible wire Defor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com