Ultralow-high-frequency-loss-power MnZn ferrite and preparation method thereof

A high-frequency loss and ferrite technology, which is applied in the advanced preparation and application of high-performance ferrite soft magnetic materials, to achieve the effects of promoting uniformity, improving sintering kinetics, and reducing high-frequency resonance bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

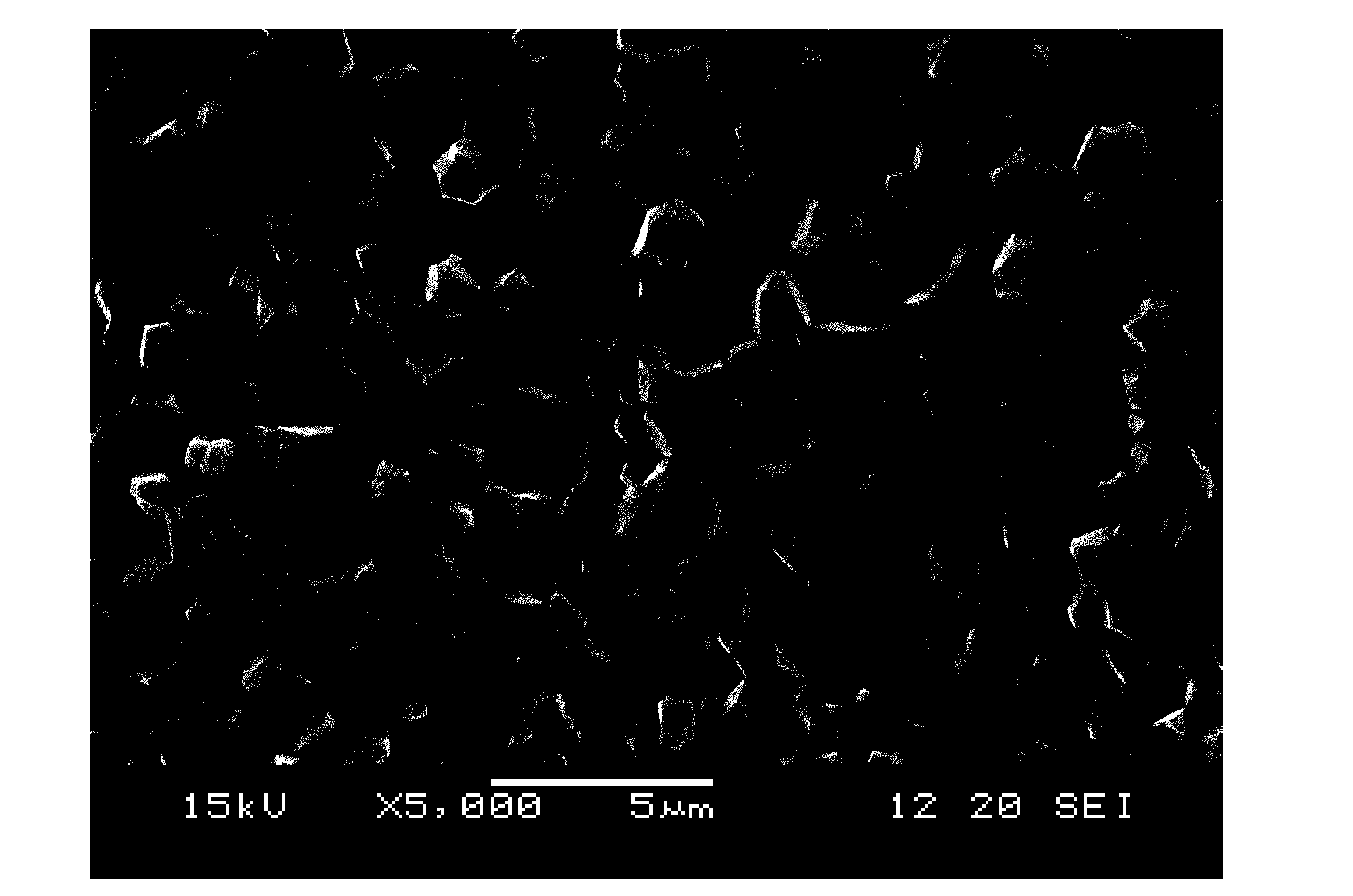

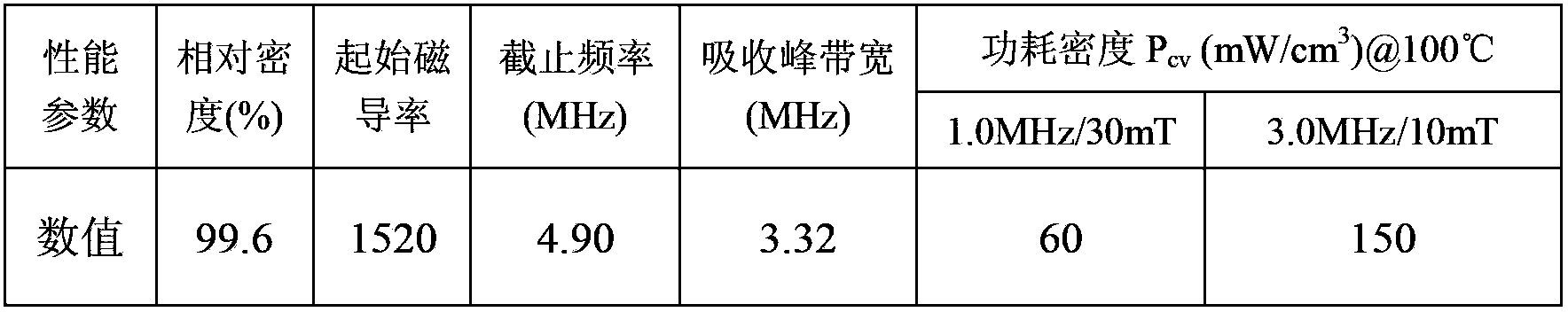

Embodiment 1

[0024] Utilize the method provided by the present invention to prepare high-frequency ultra-low loss MnZn power ferrite ring core, the preparation steps are as follows:

[0025] A. With high purity Fe 2 o 3 , MnCO 3 and ZnO as raw materials, according to The metering of the component raw materials was carried out with x=0.76, y=0.14, δ=0.10. First to Fe 2 o 3 , MnCO 3 Raw materials such as ZnO and ZnO are firstly ground separately until the average particle size reaches 0.8 μm, and then a uniformly mixed powder is obtained after 2.5 hours of ball milling. Furthermore, the mixed powder was pressed into a block (10x10x10mm) at 50MPa, and pre-fired in a nitrogen furnace. The pre-fired temperature was 850°C, and the synthesis time was 3.5 hours. The pre-fired product was determined to be a single-phase spinel structure MnZn by XRD. Ferrite;

[0026] B. Grind the pre-calcined material in an ethanol medium and perform secondary wet ball milling, and sort the secondary ball ...

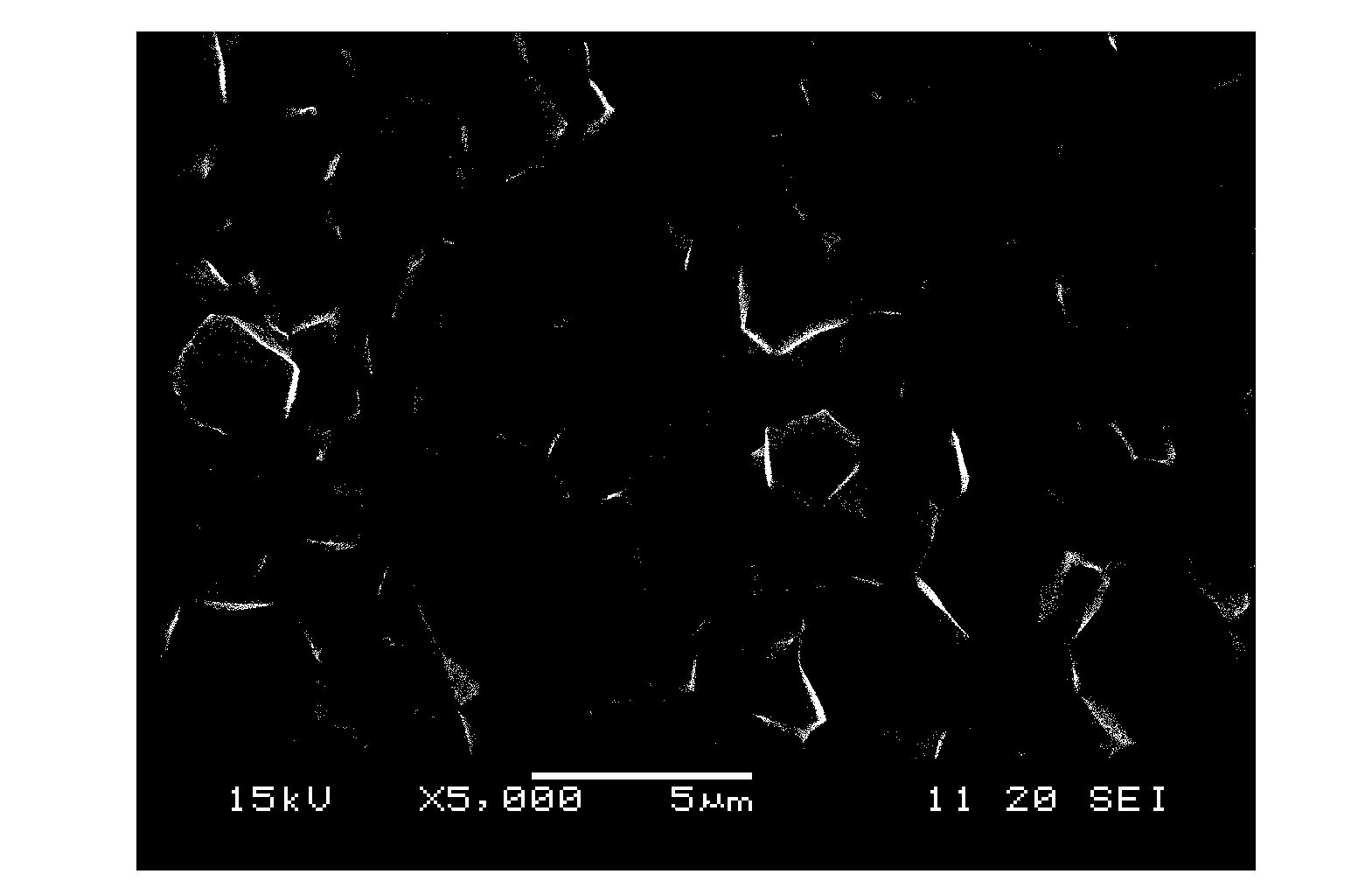

Embodiment 2

[0037] Utilize the method provided by the present invention to prepare high-frequency ultra-low loss MnZn power ferrite ring core, the preparation steps are as follows:

[0038] A. Fe 2 o 3 , MnCO 3 and ZnO as raw materials, according to Dosing of the component raw materials is carried out, where x=0.72, y=0.22, δ=0.06. First to Fe 2 o 3 , MnCO 3 Raw materials such as ZnO and ZnO are firstly ground separately until the average particle size reaches 1.0 μm, and then a uniformly mixed powder is obtained through a ball milling process for 3.5 hours. Furthermore, the mixed powder was pressed into a block (10x10x10mm) at 80MPa, and pre-fired in a nitrogen furnace. The pre-fired temperature was 900°C, and the pre-fired time was 2.5 hours. The calcined product was determined to be a single-phase spinel structure by XRD MnZn ferrite;

[0039] B. Grinding and secondary ball milling the pre-fired synthetic materials, and sorting the secondary ball milling powder particles throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com