Ultra-low-loss wide-temperature-power MnZn ferrite, preparation method and application thereof in 5G communication field

A technology of ferrite and ferrite powder, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of large power loss increase, reduce the minimum loss density, and reduce high-frequency resonance The effect of bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

[0041]The method provided by the present invention is used to prepare a high frequency ultra-low loss MnZn power ferrite toroidal magnetic core, and the preparation steps are as follows:

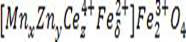

[0042]Step 1: Use high purity Fe2O3, MnCO3And ZnO as raw materials, according toCarry out the metering and batching of component raw materials, where x=0.74, y=0.10, δ=0.15.2O3, MnCO3Raw materials such as ZnO and ZnO are firstly ground separately until the average particle size reaches 0.8μm, and then a uniformly mixed powder is obtained through a 2.5-hour ball milling process. Furthermore, the mixed powder is calcined in an air furnace, the calcining temperature is 950°C, the synthesis time is 2 hours, and the calcined product is determined to be a single-phase spinel structure MnZn ferrite by XRD;

[0043]Step 2: The pre-fired synthetic material is crushed and wet ball milled twice in ethanol, and the particles of the second ball mill are sorted by a fluid cyclone to obtain an average particle size of...

Embodiment 12~ Embodiment 19

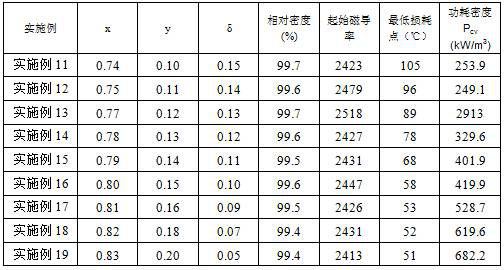

[0050]Based on the process of Example 11, changing Fe2O3Then, perform performance tests on the permeability spectrum and power loss density (100kHz / 200mT) of the obtained MnZn ferrite toroidal core. The performance parameters are shown in Table 1.

[0051]Table 1:

[0052]

[0053]Based on Example 11 to Example 19, it can be seen from the experimental data in Table 1: that the single-phase spinel structure of MnZn ferrite has Fe2O3With the increase of the content, the lowest loss point of the obtained MnZn ferrite moves to low temperature. However, as Fe2O3An increase in the amount of addition will lead to an increase in loss, so that the loss of Mn-Zn ferrite will increase; when the Fe2O3When the content is 0.79 to 0.81, the effect of the obtained single-phase spinel structure MnZn ferrite is the best.

Embodiment 21~ Embodiment 23

[0055]On the basis of Example 11, when preparing single-phase spinel structure MnZn ferrite, CeO2Particles. Specifically: with high purity Fe2O3, MnCO3, ZnO and CeO2As raw materials, in accordance withCarry out the metering and batching of component raw materials, where x=0.80, y=0.15, z=0.008, δ=0.10. First of Fe2O3, MnCO3Raw materials such as ZnO and ZnO are firstly ground separately until the average particle size reaches 0.8μm, and then a uniformly mixed powder is obtained through a 2.5-hour ball milling process. Furthermore, the mixed powder was calcined in an air furnace, the calcining temperature was 950°C, and the synthesis time was 2 hours. The calcined product was determined to be a single-phase spinel structure MnZn ferrite by XRD.

[0056]Other processes and parameters are the same as in Example 11. Then the magnetic permeability spectrum and power loss density (100kHz / 200mT) of the obtained MnZn ferrite toroidal core were tested. The performance parameters are shown in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com