Magnetic nickel-zinc ferrite material and preparation method thereof

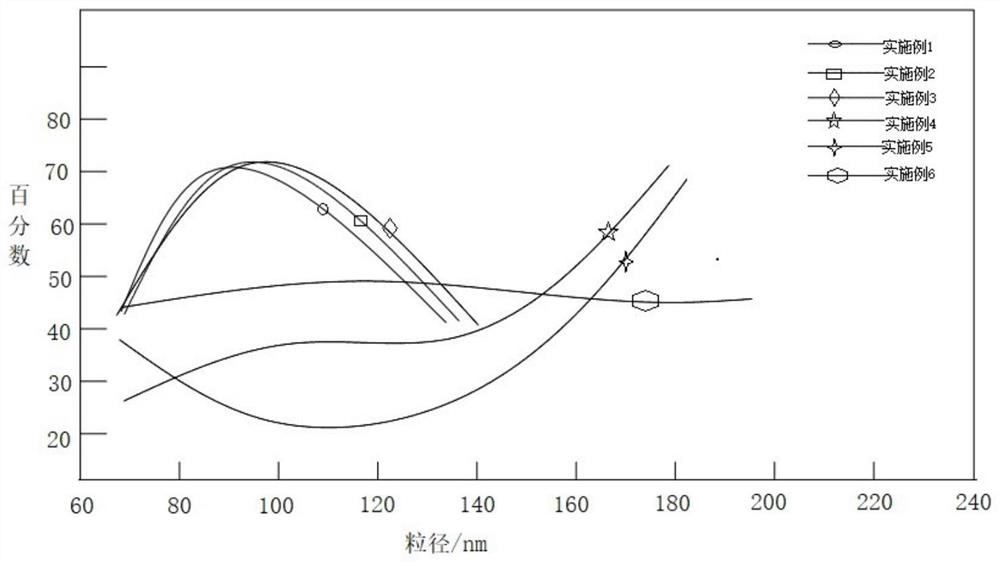

A nickel-zinc ferrite and magnetic technology, applied in the field of magnetic nickel-zinc ferrite material and its preparation, can solve the problems of low quality of nickel-zinc ferrite, large difference in physical properties, insufficient sintering, etc. Frequency resonance bandwidth, increase the ball milling area, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1, one-time batching: put the raw materials , and NiO are mixed uniformly in a mixer to form a mixed material according to the mass ratio of 60.2:14.2:18.1;

[0033] Step 2, primary ball milling: the mixed material in step 1 is placed in a ball milling jar for ball milling; the diameters of the first sphere, the second sphere and the third sphere are 15mm, 10mm and 5mm respectively, and the first sphere, the second sphere The mass ratio of the second sphere and the third sphere is 1:3:2; the mass ratio of the total mass of the first sphere, the second sphere and the third sphere to the powder is 9:1; the rotational speed is 250r / min. Three balls with different diameters are used for ball milling, which can target particles of different particle sizes. Because the particle sizes are not equal, the gaps between particles are not equal, and three balls with different diameters. It can shuttle in the matching gap, increase the ball milling area, not only can grind ...

Embodiment 2

[0044] Step 1, one-time batching: put the raw materials , and NiO are mixed uniformly in a mixer to form a mixed material according to the mass ratio of 68.9:10.3:14.6;

[0045] Step 2, primary ball milling: the mixed material in step 1 is placed in a ball milling jar for ball milling; the diameters of the first sphere, the second sphere and the third sphere are 15mm, 10mm and 5mm respectively, and the first sphere, the second sphere The mass ratio of the second sphere and the third sphere is 1:3:2; the mass ratio of the total mass of the first sphere, the second sphere and the third sphere to the powder is 9:1; the rotational speed is 240r / min.

[0046] Step 3. Pre-burning: heat up the mixture obtained from the primary ball milling to 900°C under the protection of nitrogen, keep it warm for 2 hours, and cool down with the furnace to obtain primary sintering powder; make part of the raw material spinel first, and increase the secondary The performance of the sintered finis...

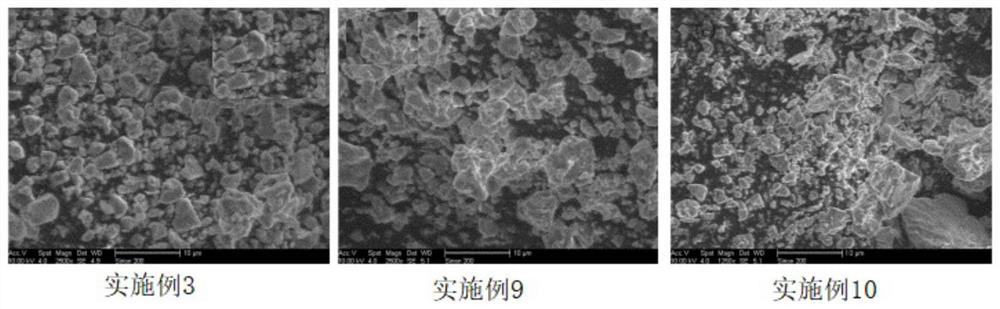

Embodiment 3

[0055] Step 1, one-time batching: put the raw materials , and NiO are mixed uniformly in a mixer to form a mixed material according to the mass ratio of 65.2:11.1:15.2;

[0056] Step 2, primary ball milling: the mixed material in step 1 is placed in a ball milling jar for ball milling; the diameters of the first sphere, the second sphere and the third sphere are 15mm, 10mm and 5mm respectively, and the first sphere, the second sphere The mass ratio of the second sphere and the third sphere is 1:3:2; the mass ratio of the total mass of the first sphere, the second sphere and the third sphere to the powder is 9:1; the rotational speed is 240r / min.

[0057] Step 3. Pre-burning: heat up the mixture obtained from the primary ball milling to 900°C under the protection of nitrogen, keep it warm for 2 hours, and cool down with the furnace to obtain primary sintering powder; make part of the raw material spinel first, and increase the secondary The performance of the sintered finis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com