Measuring and correcting method of ship draft measuring device

A draft, measurement and correction technology, applied in measuring devices, lubricating indicating devices, liquid/fluid solids measurement, etc., can solve problems such as the influence of water measurement data, which cannot be excluded, and achieve accurate draft measurement data, reasonable design and effective. The effect of accurate draft measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

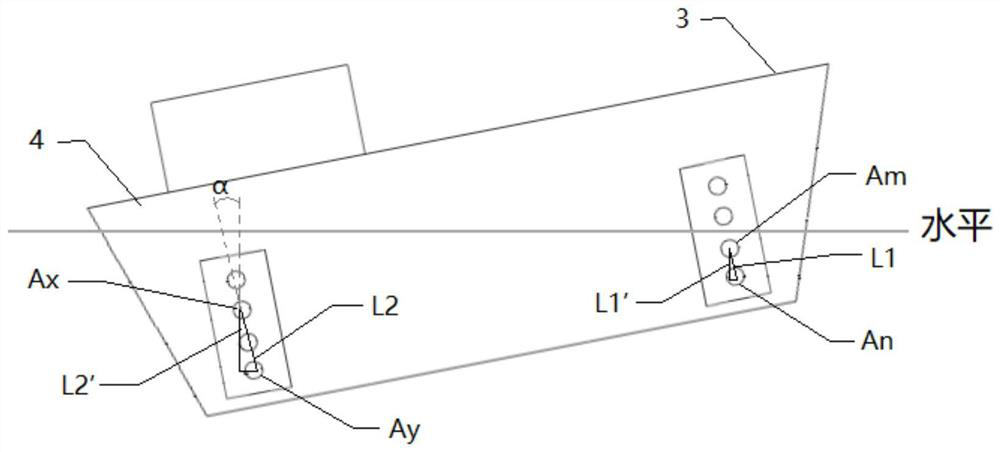

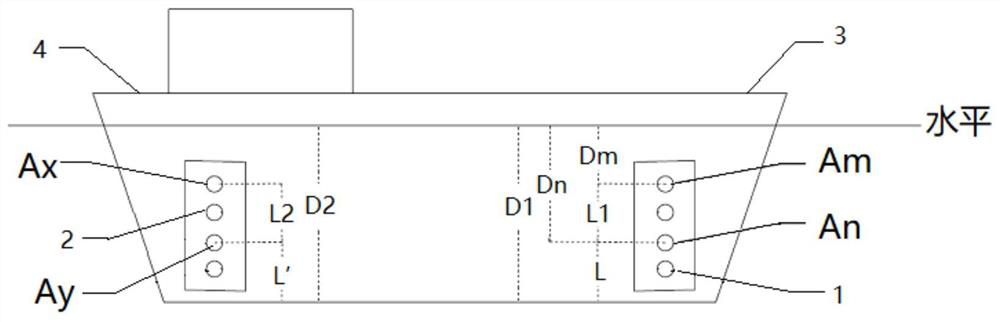

[0030] A method for measuring and correcting a ship's draft depth measuring device in this embodiment is characterized in that the depth measuring device includes a plurality of liquid level sensors, and is divided into two groups, which are respectively installed at the bow 3 and the stern 4 of the ship, They are the bow liquid level sensor 1 and the stern liquid level sensor 2 respectively. The number of the bow liquid level sensors 1 is multiple, at least 2, and they are arranged vertically from top to bottom. The number of position sensors 2 is multiple, at least 2, and they are arranged vertically from top to bottom;

[0031] The measurement and correction method of the depth measurement device is as follows:

[0032] (1) Assuming that the ship does not tilt;

[0033] (1-1) Measurement of ship's bow draft:

[0034] Choose two bow liquid level sensors with different heights, and record them as Am and An from top to bottom. It is known that the measured value of Am is Pm,...

Embodiment 2

[0051] Based on Embodiment 1, a method for measuring and correcting a ship’s draft depth measuring device in this embodiment selects multiple groups of bow liquid level sensors, and the number of each group of bow liquid level sensors is 2. After conversion, multiple Pressure data, take the average value, get The average value is the measured bow average draft; multiple sets of stern liquid level sensors are selected, and the number of stern liquid level sensors in each group is 2, and converted to obtain multiple pressure data, and the average value is taken. have to The average value is the measured mean draft of the stern;

[0052] Under this scheme, even if a small number of liquid level sensors fail, accurate draft data can be obtained.

[0053] In summary, the present invention is simple in structure, reasonable in design, and is used for the measurement of the draft of a boat. Compared with the measurement data obtained by conventional measurement, the measurement d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com