A method for preparing hot-dip coating transmission samples by reduction-oxidation delamination method

A hot-dip plating and sample technology, which is applied in the field of hot-dip plating and transmission detection, can solve the problems of less sample thin area, adhesive glue falling off into pieces, samples detaching from copper rings, etc., and achieves the effect of simple sample preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

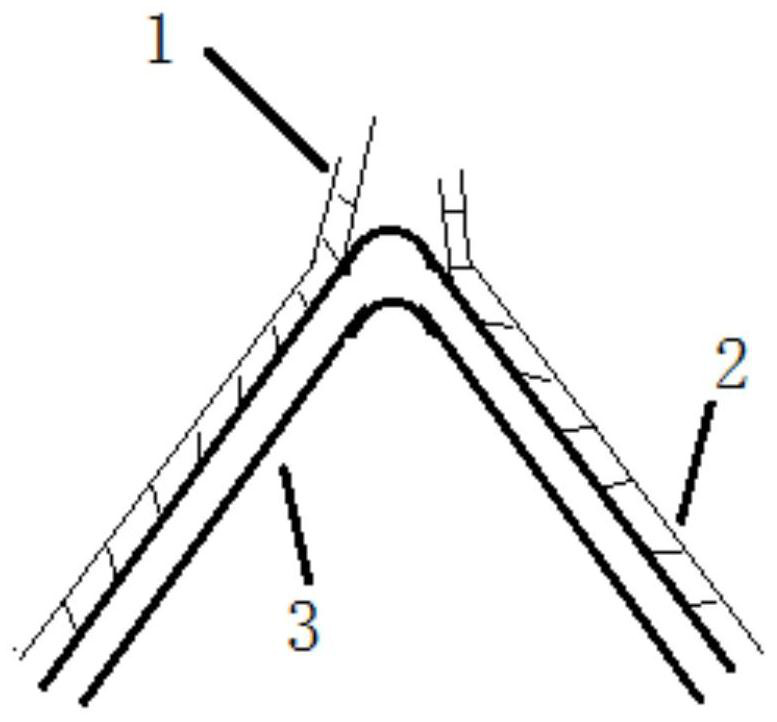

Image

Examples

Embodiment 1

[0028] Example 1: Taking IF steel hot-dip galvanized as an example to illustrate the method of preparing the transmission sample of the hot-dip layer by the delamination method.

[0029] 1) Take the IF steel plate 120mm*220mm, after pickling-alkali cleaning, the roughness is 1.1μm, wipe it with alcohol, and put it into the hot-dip galvanizing simulator;

[0030] 2) Reduction treatment: the annealing temperature is set at 850°C, and the atmosphere is 10vol%H 2 +90vol%N 2 , reduce the surface of the steel plate, and the reduction time is 2 minutes;

[0031] 3) Oxidation treatment: The dew point of the oxidizing atmosphere is set at 25°C, the temperature in the furnace is 850°C, the oxidation time is 3 minutes, and then the temperature begins to drop to 480°C

[0032] 4) Hot-dip plating treatment: immerse in the hot-dip plating bath for 5 seconds, and use an air knife to purge after leaving the hot-dip bath, so that the thickness of the coating on the steel plate is about 6um, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com