A sample preparation method based on hot wire method

A technology of hot wire method and time, which is applied in the preparation, sampling, and instrumentation of test samples, which can solve problems such as uneven composition and composition change, and achieve the effect of solving uneven composition, eliminating composition change, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

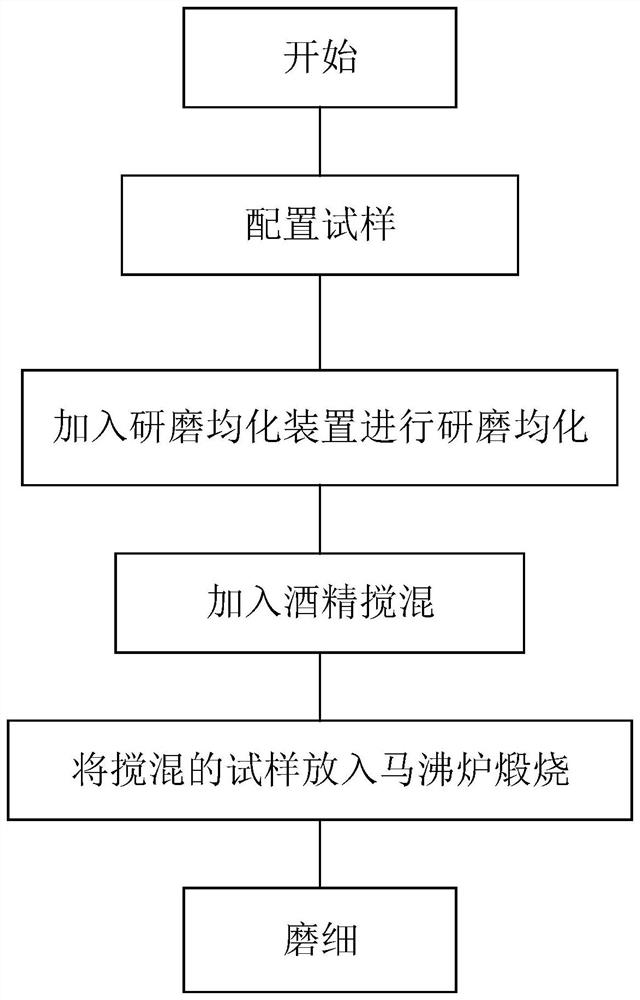

[0029] In order to solve the problem of uneven composition caused by crystal precipitation in the homogenization process of the traditional molten water quenching sample preparation method, and the composition change caused by ion exchange in the water quenching process, the general idea of the solution provided by this application is as follows, including the following steps:

[0030] (1) Prepare the sample according to the process requirements, put the prepared sample (50g slag sample) into the pulverizer for grinding and homogenization, and the time is more than 40s;

[0031] (2) Put the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com