Method for preparing hot-dip coating transmission sample by reduction-oxidation delaminating method

A hot-dip coating and sample technology, which is applied in the field of hot-dip coating technology and transmission detection, can solve problems such as damage, large test influence, and low success rate of sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

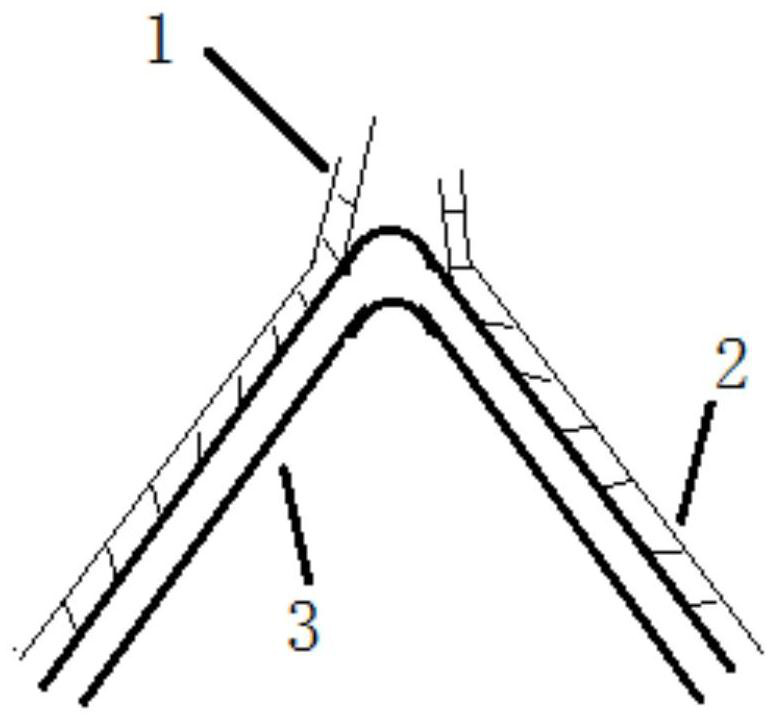

Image

Examples

Embodiment 1

[0028] Example 1: Taking IF steel hot-dip galvanized as an example to illustrate the method of preparing the transmission sample of the hot-dip layer by the delamination method.

[0029] 1) Take the IF steel plate 120mm*220mm, after pickling-alkali cleaning, the roughness is 1.1μm, wipe it with alcohol, and put it into the hot-dip galvanizing simulator;

[0030] 2) Reduction treatment: the annealing temperature is set at 850°C, and the atmosphere is 10vol%H 2 +90vol%N 2 , to restore the surface of the steel plate, and the reduction time is 2 minutes;

[0031] 3) Oxidation treatment: The dew point of the oxidizing atmosphere is set at 25°C, the temperature in the furnace is 850°C, the oxidation time is 3 minutes, and then the temperature begins to drop to 480°C

[0032] 4) Hot-dip plating treatment: immerse in the hot-dip plating bath for 5 seconds, and use an air knife to purge after leaving the hot-dip bath, so that the thickness of the coating on the steel plate is about 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com