Spliced plastic oil tank for generator set

A technology for plastic fuel tanks and generator sets, applied in engine components, machines/engines, charging systems, etc., can solve the problem that the fuel tank cannot be used universally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

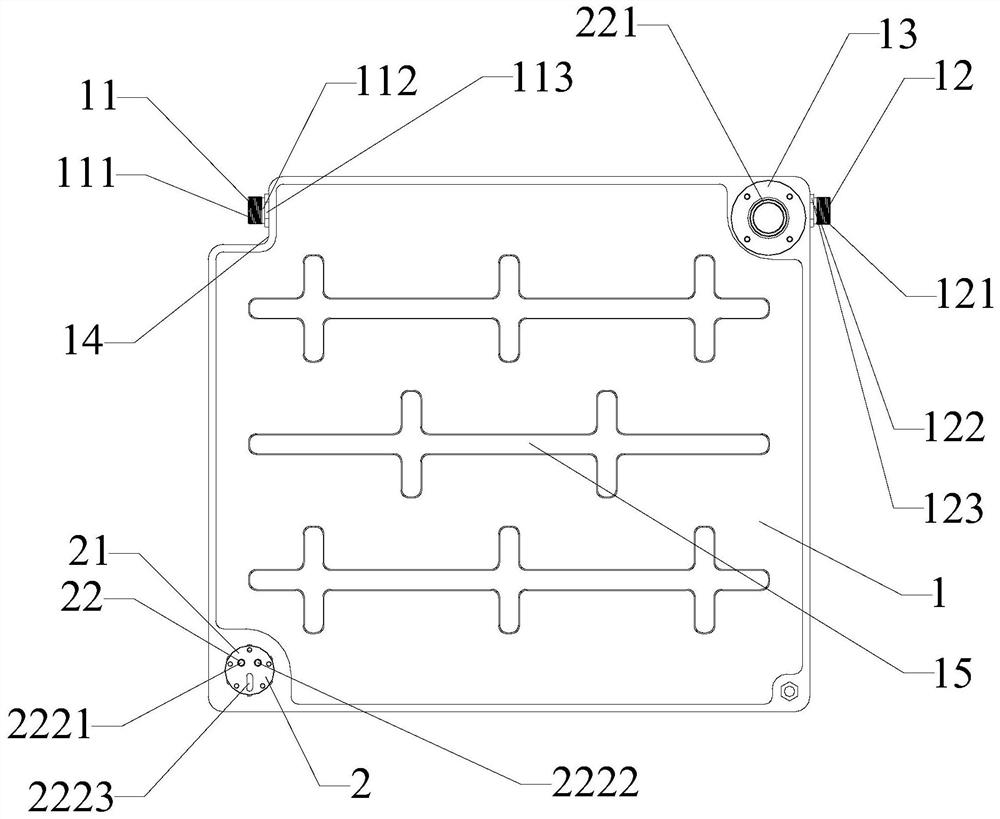

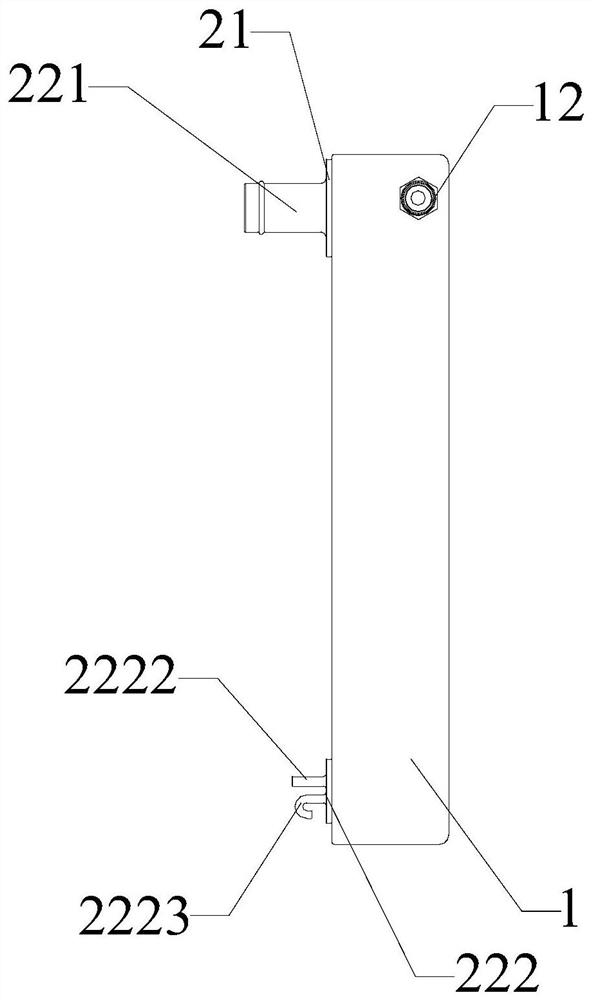

[0037] Please refer to Figure 1 to Figure 4, a spliced plastic fuel tank for generator sets, comprising more than one plastic fuel tank monomer 1, a first interface 11 is provided on one side of the plastic fuel tank monomer 1, and the plastic fuel tank monomer 1 is opposite to the first The other side of the first interface 11 is provided with a second interface 12, the axes of the first interface 11 and the second interface 12 coincide, and the corners of the upper part of the plastic fuel tank unit 1 are provided with more than two flanges The interface 13, the first interface 11 and the second interface 12 have the same diameter. Also includes a flange connection fitting 2, the flange connection fitting 2 is composed of a flange 21 and a single functional fitting 22 connected to the flange 21, the functional fitting 22 includes a fuel port 221, an oil inlet and return pipe 222 , oil gauge or oil alarm. The oil inlet and oil return pipe member 222 includes an oil inlet...

Embodiment 2

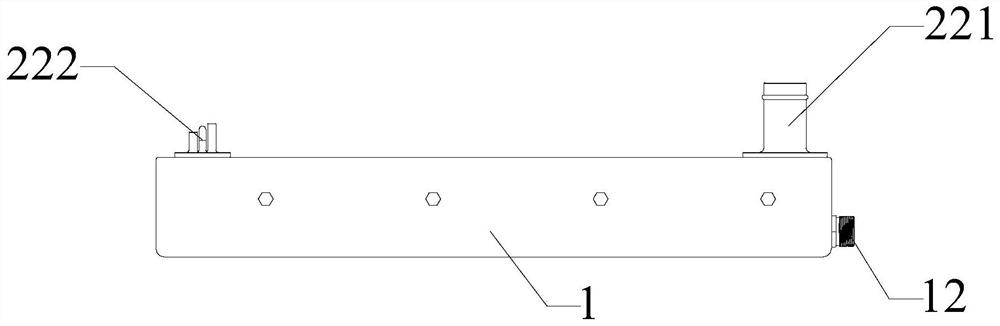

[0039] Please refer to Figure 5 , a spliced plastic fuel tank for generator sets, a spliced plastic fuel tank for generator sets, comprising more than one plastic fuel tank unit 1, one side of the plastic fuel tank unit 1 is provided with a first interface 11. The plastic oil tank unit 1 is provided with a second interface 12 on the other side of the first interface 11, the axes of the first interface 11 and the second interface 12 coincide, and the upper part of the plastic oil tank unit 1 Four flange interfaces 13 are provided. Also includes a flange connection fitting 2, the flange connection fitting 2 is composed of a flange 21 and a single functional fitting 22 connected to the flange 21, the functional fitting 22 includes a fuel port 221, an oil inlet and return pipe 222 , oil gauge or oil alarm. The oil inlet and oil return pipe member 222 includes an oil inlet pipe joint 2221 , an oil return pipe joint 2222 and a vent pipe 2223 . The oil gauge is a mechanical o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com