Four-arm telescopic mechanism of aerial work vehicle

A technology of aerial work vehicle and telescopic mechanism, which is applied in the direction of lifting device, etc., can solve the problems of high cost, the number of boom sections cannot be too many, and the requirements of multi-section boom telescopic boom cannot be met, so as to achieve high telescopic efficiency and improve work performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

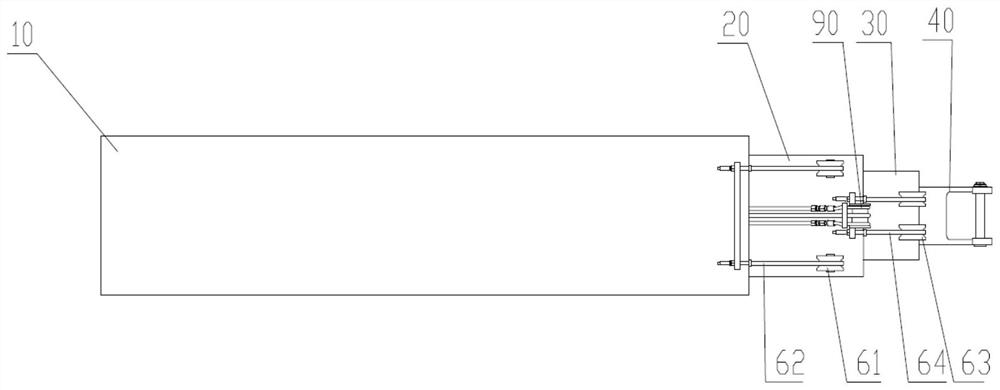

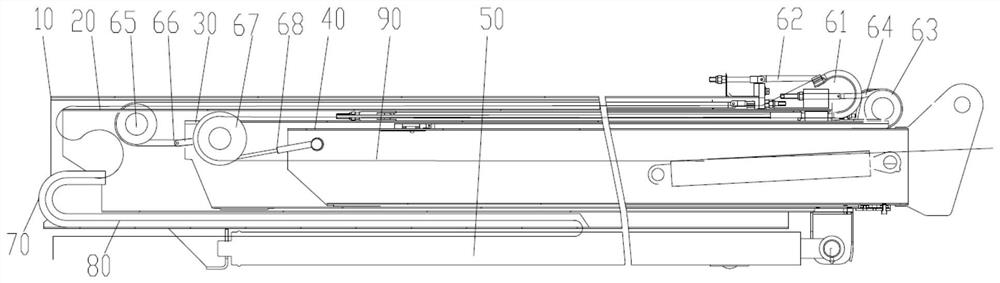

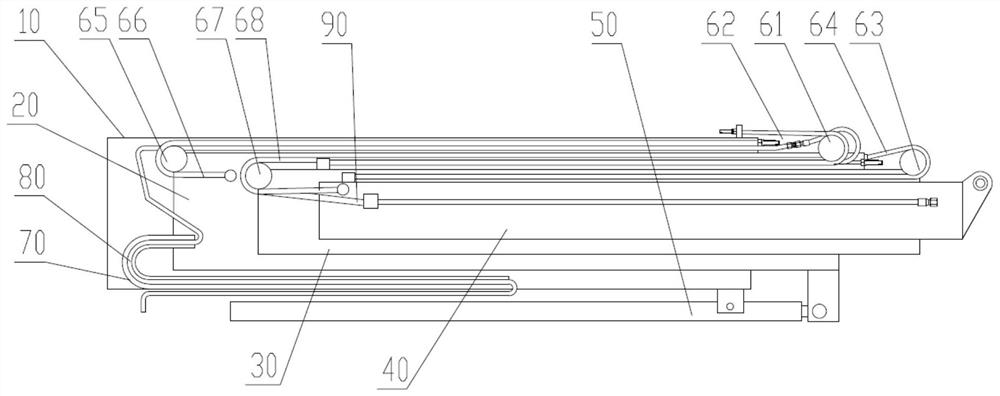

[0017] refer to Figure 1 to Figure 3 , the present invention provides a four-section boom telescoping mechanism for an aerial work vehicle, comprising a first arm body 10, a second arm body 20, a third arm body 30, and a fourth arm body 40. The first arm body 10 is provided with a drive Mechanism 50, the output end of the driving mechanism 50 acts on the second arm body 20, and is used to drive the second arm body 20 to perform telescopic movement relative to the first arm body 10, the second arm body 20, the third arm body 30, the fourth arm body The bodies 40 are respectively connected by a transmission mechanism. When the second arm body 20 performs telescopic movement, the third arm body 30 relative to the second arm body 20 , and the fourth arm body 40 performs synchronous telescopic movement relative to the third arm body 30 . The synchronous telescopic movement between the arm bodies makes the telescopic efficiency of the four-section boom high. It is suitable for aeri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com