Shifter system with variable shifting force

A shifter and gear force technology, which is applied in the testing of instruments, components with teeth, and mechanical components, etc., can solve problems such as difficulty in shifting force, reduce time and cost, save development cycle, and conform to platformization and intelligent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

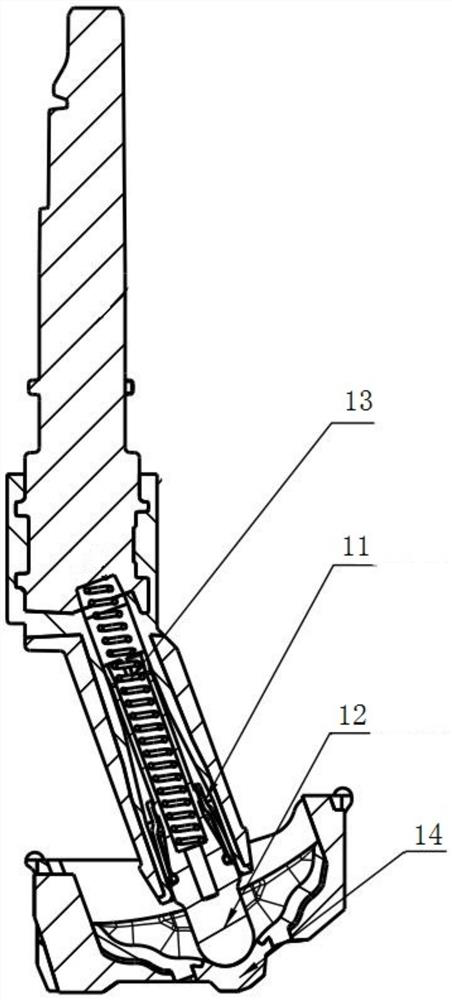

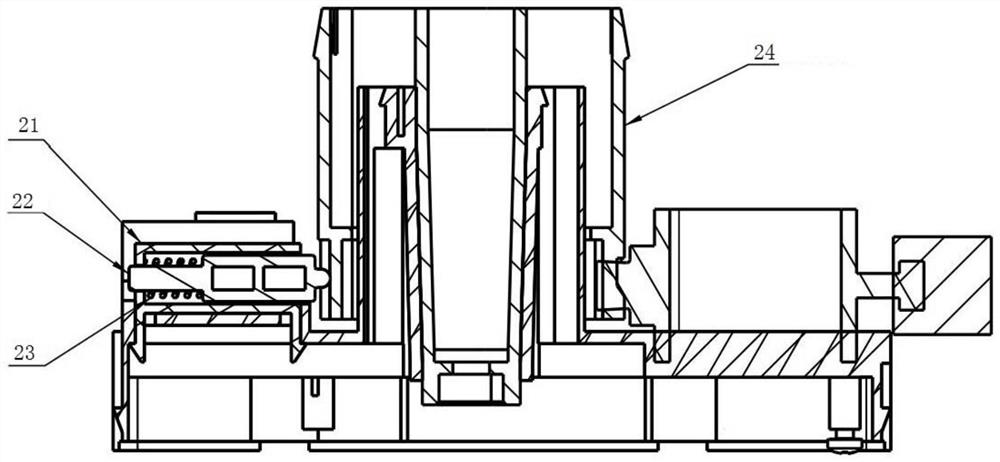

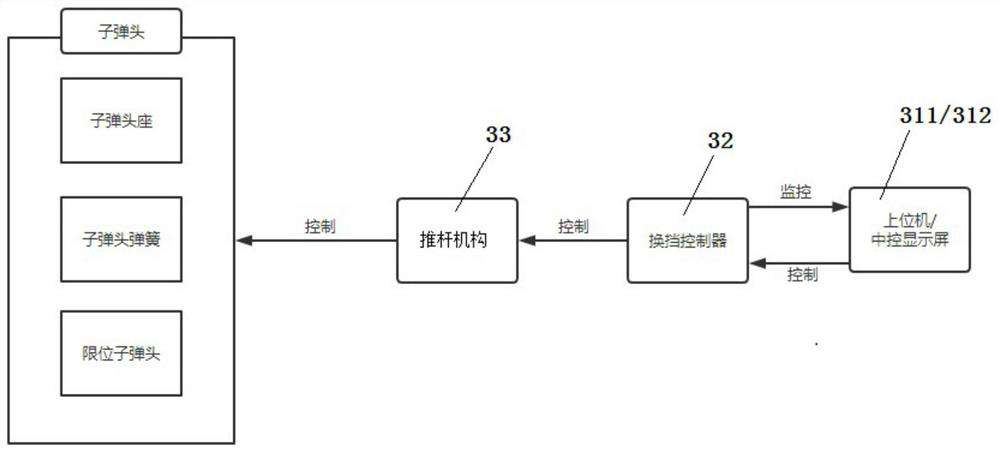

[0026] combine Figure 3 to Figure 5 , a shifter system with variable gear force, including a host computer 311, a shift controller 32, a push rod mechanism 33, a bullet and a shift sense module 14 or a knob body 24, wherein the shift sense module 14 Corresponds to the pushrod shifter (see Figure 4 ), the knob body 24 corresponds to the knob type shifter (see Figure 5 ), the bullet structure and principle of the push rod type shifter and the knob type shifter are basically the same.

[0027] See image 3 , the host computer 311 is connected to the shift controller 32 through an emulator (not shown), and the shift controller 32 is electrically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com