Driving mechanism for realizing different time sequence motions of grating blades

A driving mechanism and blade technology, applied in the field of automobile interior and exterior decoration, can solve the problems of high production cost and complex spatial structure, and achieve the effect of asynchronous driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

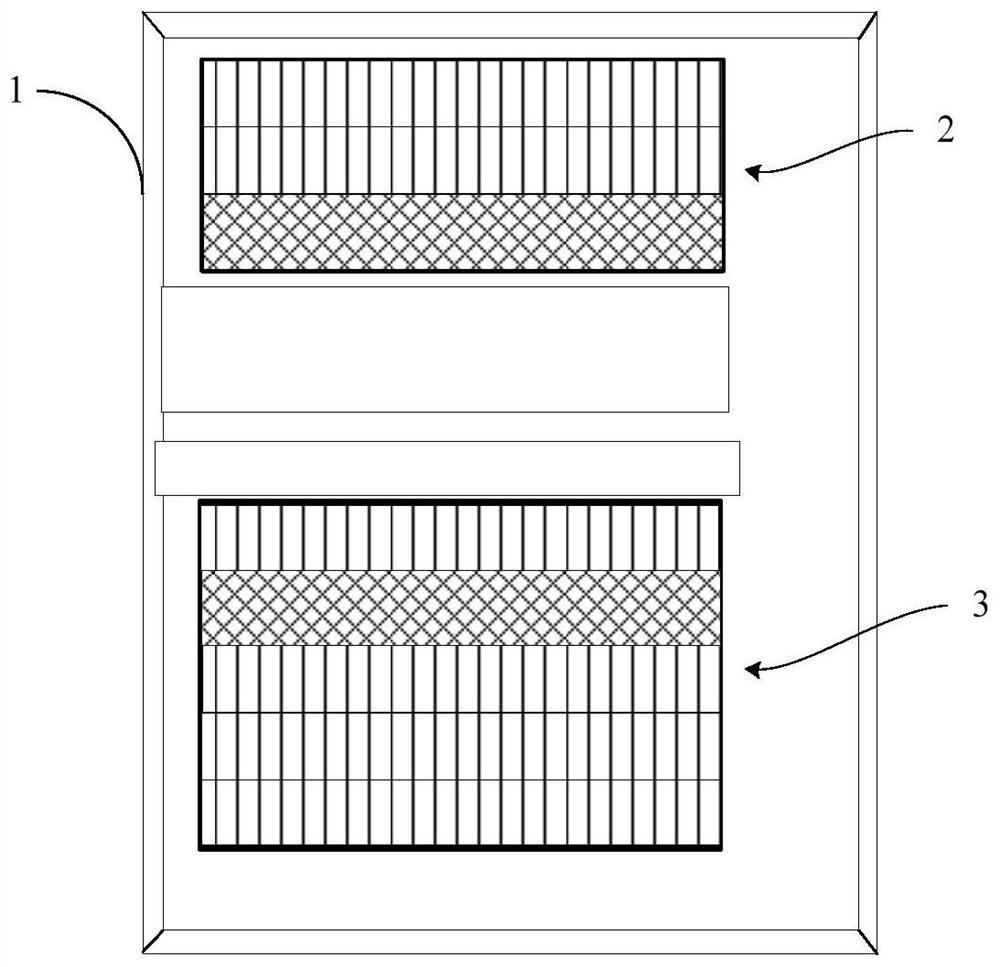

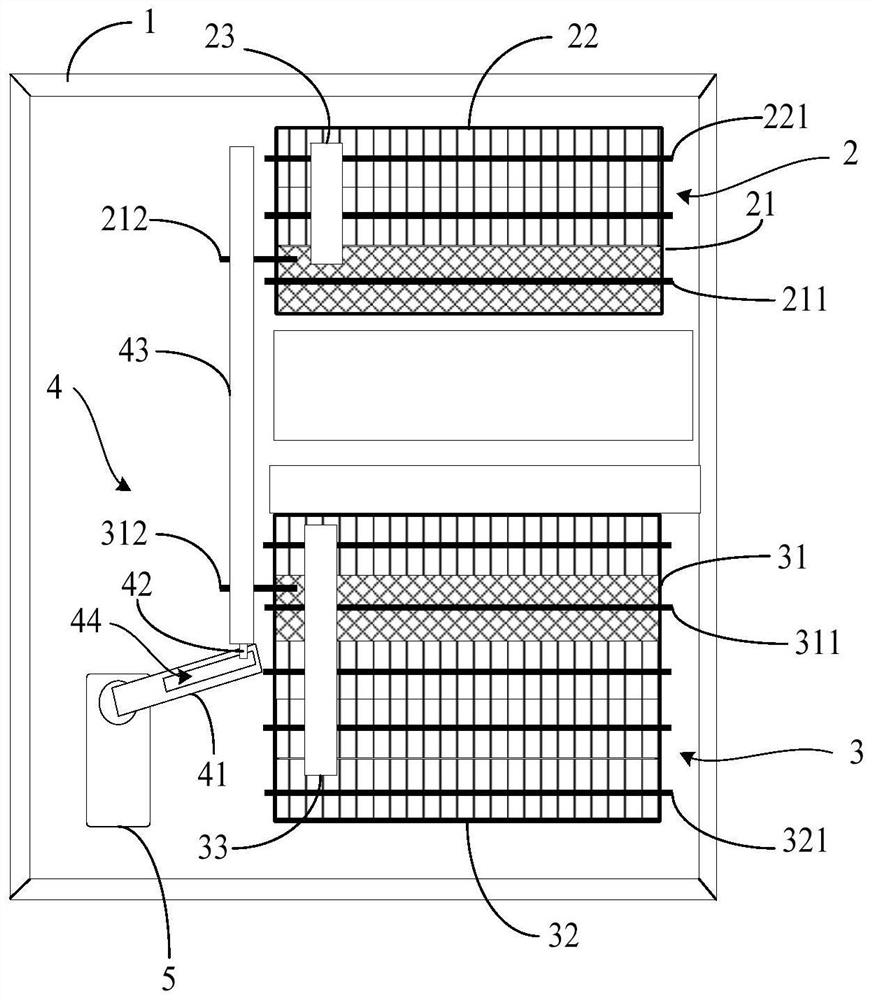

[0026] Such as figure 1 with figure 2 As shown, a driving mechanism for implementing different time-sequential movements of grille blades according to Embodiment 1 of the present invention includes a frame 1 on which a first grille 2 on its upper part and a second grille 3 on its lower part are arranged. , the first grid 2 and the second grid 3 are connected with the motor 5 through the crank linkage mechanism 4, and the motor 5 realizes the asynchronous opening of the first grid 2 and the second grid 3 by controlling the movement of the crank linkage mechanism 4 and off.

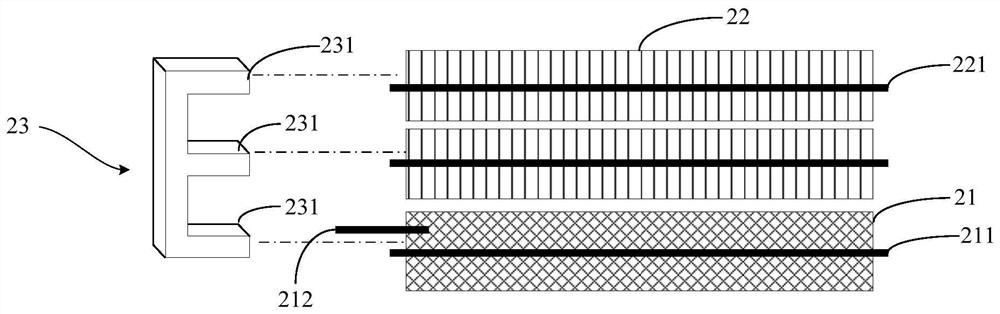

[0027] Wherein, the first grid 2 includes a first driving vane 21 and a plurality of first driven vanes 22 , and the first driving vane 21 and the plurality of first driven vanes 22 are fixedly connected to a first connecting rod 23 .

[0028] Specifically, the first driving blade 21 is provided with a driving blade rotating shaft 211 and a first driving shaft 212, both ends of the driving blade rotating...

Embodiment 2

[0043] Such as Figure 8 As shown, a driving mechanism for implementing different time-sequential movements of grille blades according to Embodiment 2 of the present invention includes a frame 1 on which a first grille 2, a second grille 3, a third grille 2' and For the fourth grid 3', the first grid 2 and the third grid 2' are arranged symmetrically, and the second grid 3 is arranged symmetrically with the fourth grid 3'. The first grid 2, the second grid 3, the third grid 2' and the fourth grid 3' are connected to the motor 5 through the crank linkage 4', and the motor 5 realizes the first grid by controlling the crank linkage 4'. The asynchronous opening and closing of the first grid 2 and the second grid 3, and the asynchronous opening and closing of the third grid 2' and the fourth grid 3'.

[0044] The crank-link mechanism 4' comprises a connecting shaft 41', a cross bar 43' provided with a blocking point 42', and a driving rod 44' symmetrically arranged at both ends of...

Embodiment 3

[0048] Such as Figure 9 As shown, a driving mechanism for implementing different time-sequence movements of grille blades according to Embodiment 3 of the present invention includes a frame 1 on which a first grille 2, a second grille 3, a third grille 2' and For the fourth grid 3', the first grid 2 and the third grid 2' are arranged symmetrically, and the second grid 3 is arranged symmetrically with the fourth grid 3'. The first grid 2 and the second grid 3 are connected with the motor 5 through the crank linkage mechanism 4 , and the motor 5 realizes the asynchronous opening and closing of the first grid 2 and the second grid 3 by controlling the crank linkage mechanism 4 . The third grid 2' and the fourth grid 3' are connected with the motor 5' through the crank linkage 4', and the motor 5' realizes the third grid 2' and the fourth grid by controlling the crank linkage 4'. 3' for asynchronous turn-on and turn-off.

[0049] The structure of above-mentioned crank-link mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com