Device for manufacturing battery pole piece and method

A battery pole piece and manufacturing device technology, which is applied in the field of battery manufacturing, can solve problems such as mismatching processing hours, and achieve the effects of improving pole piece production efficiency, improving transmission accuracy, and stabilizing pole piece tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

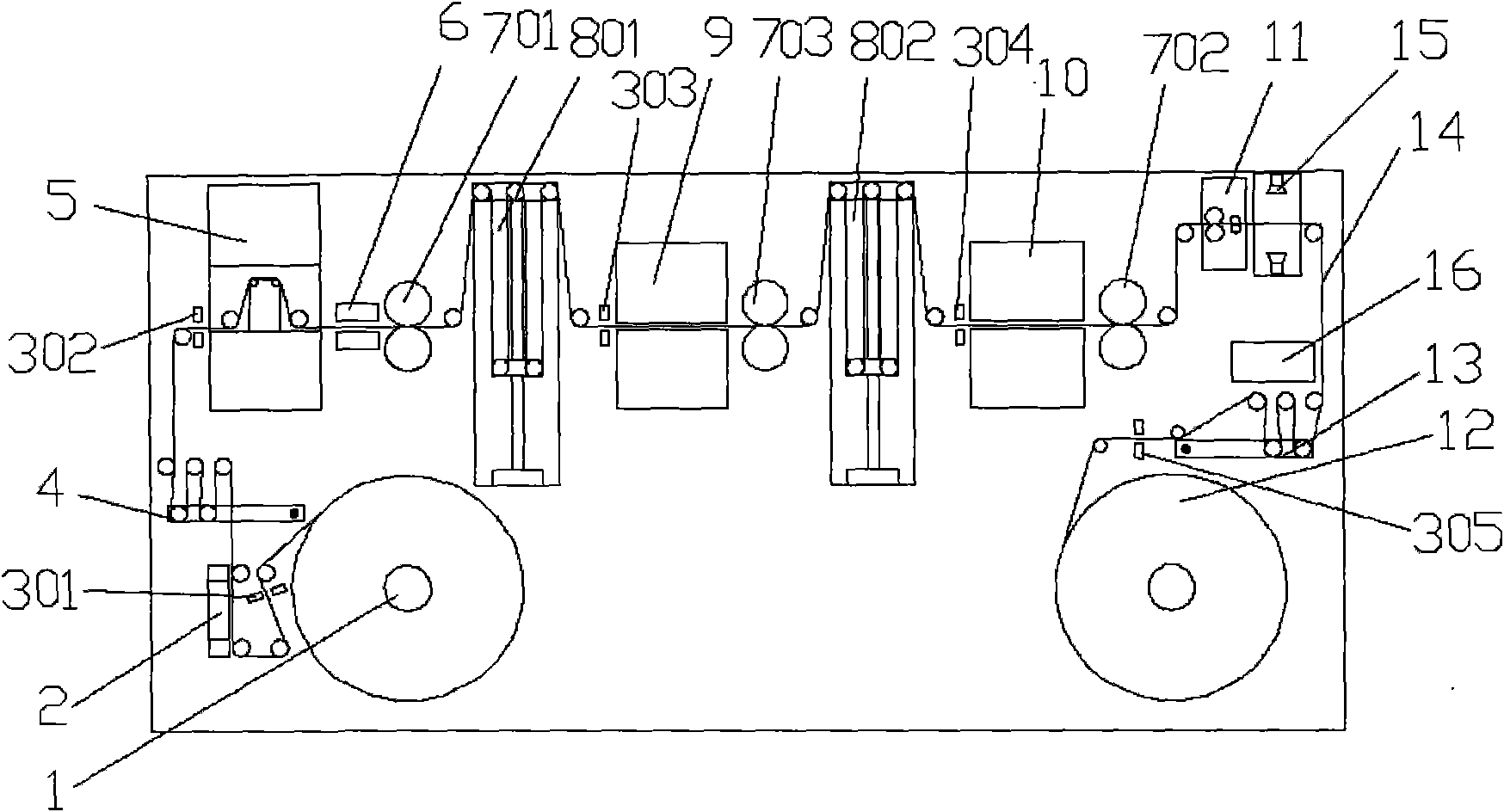

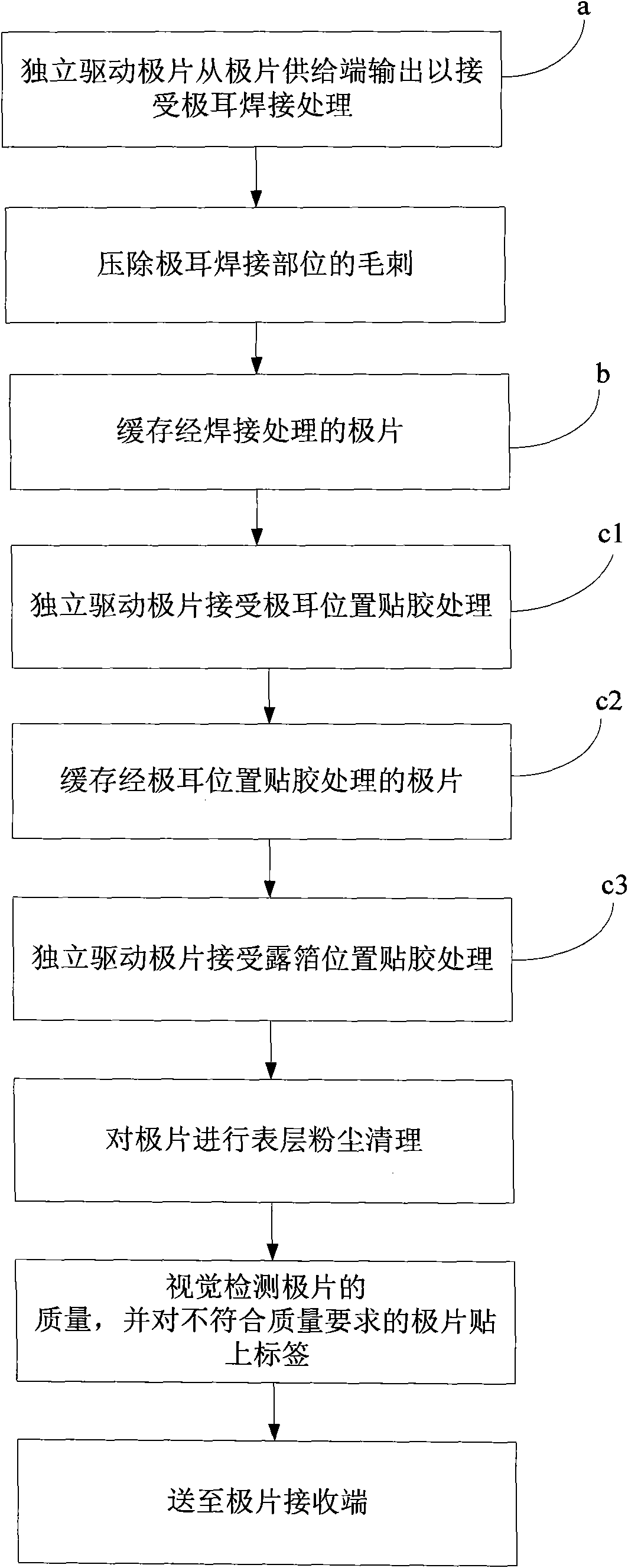

[0037] Please refer to figure 1 The battery pole piece manufacturing device includes a pole piece supply module 1, a tab welding module 5, a first drive module 701, a first buffer module 801, a glue module, and a second drive module 702 arranged in order in accordance with the conveying direction of the pole piece 14. And the pole piece receiving module 12, wherein the battery pole piece installed on the pole piece supply module 1 is driven and output by the first driving module 701, processed by the tab welding module 5, and the pole piece welded with the tab is transported to the first buffer module 801 , perform buffering. Driven by the second driving module 702 , the buffered pole pieces of the first buffering module 801 are processed by the gluing module, and the glued pole pieces are finally sent to the pole piece receiving module 12 . In this process, the first driving module 701 and the second driving module 702 are respectively responsible for driving the pole piece n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com