An automobile sub-dashboard armrest assembly

A sub-dashboard, armrest technology, applied in the direction of armrests, passenger space, etc., to reduce costs, improve comfort, and improve aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

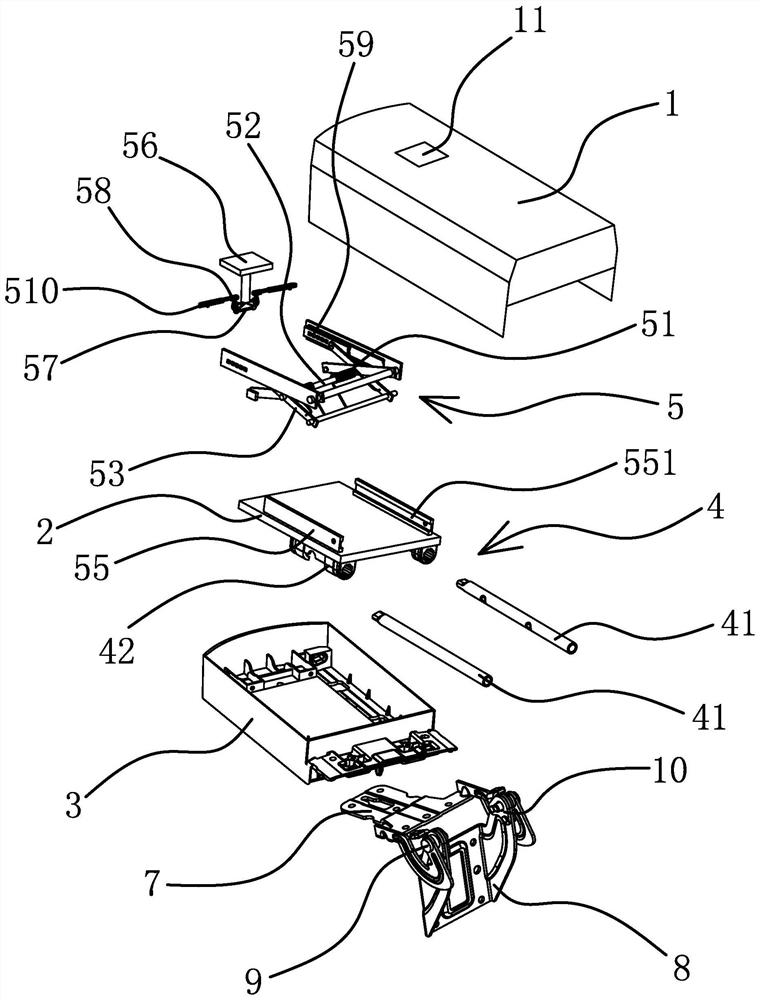

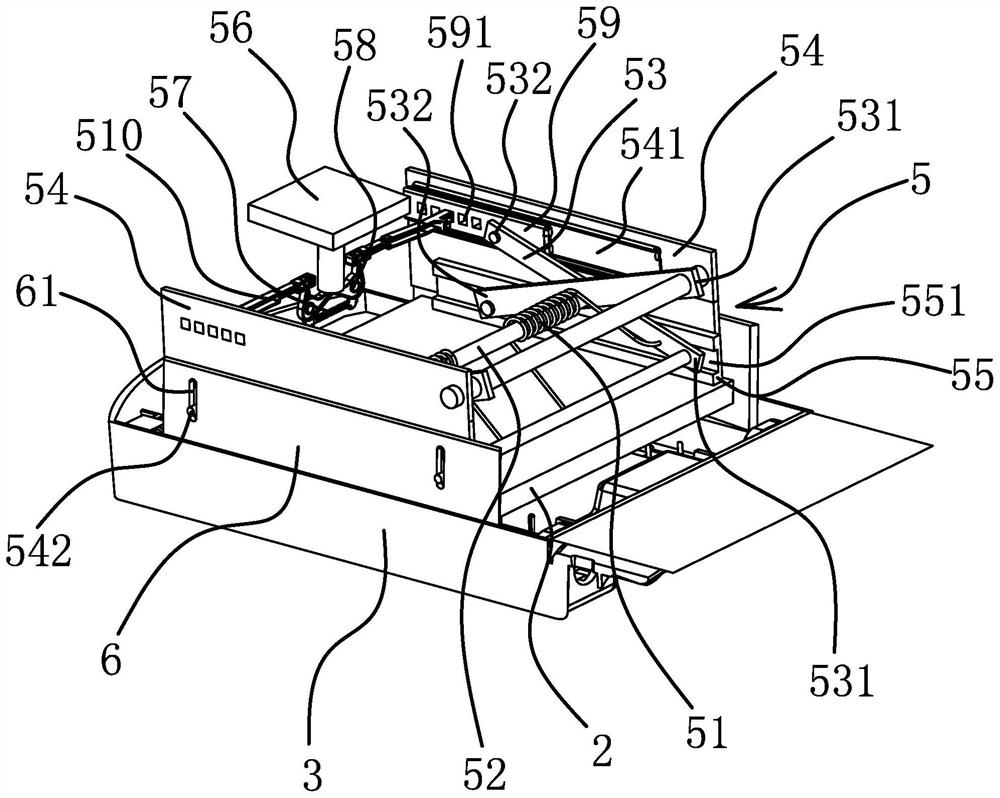

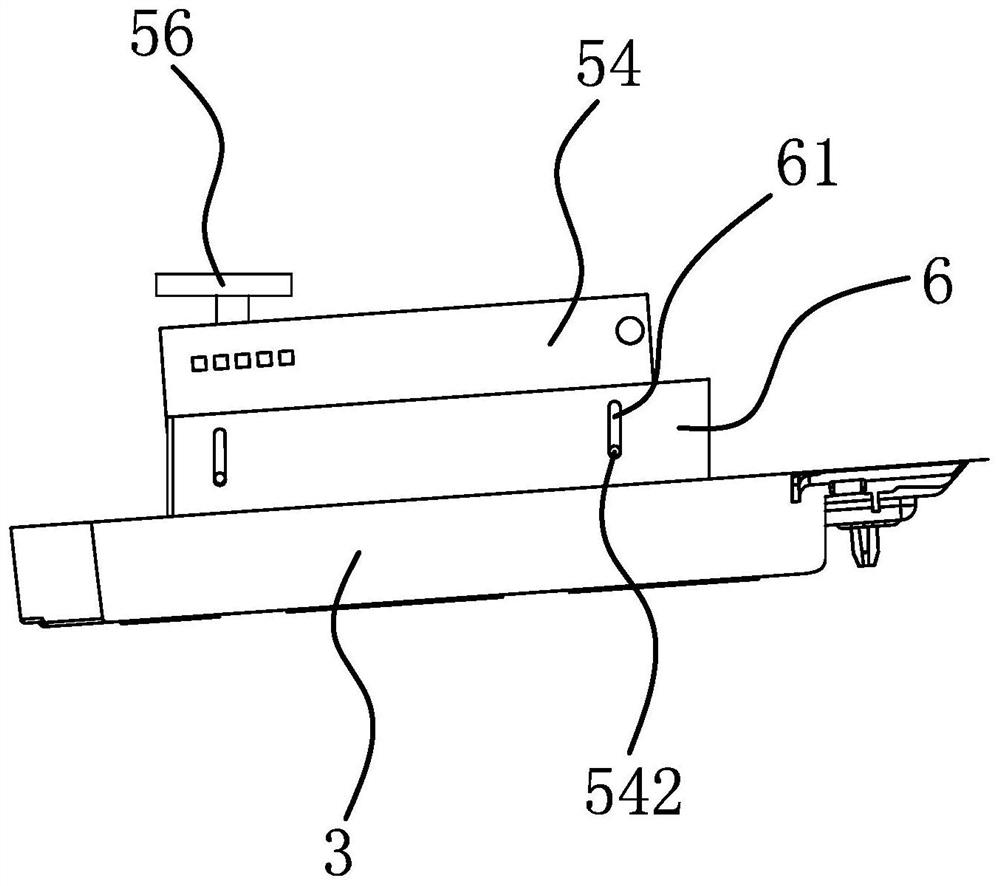

[0032] like figure 1 As shown, the sub-instrument panel armrest assembly of the automobile includes a panel 1 , a sliding plate 2 , a base plate 3 , a sliding mechanism 4 , a lifting mechanism 5 , a first fixing bracket 7 and a second fixing bracket 8 .

[0033] like Figure 7 As shown, the first fixing bracket 7 is fixedly connected with the base plate 3, the second fixing bracket 8 is fixedly connected with the storage box of the sub-instrument panel, the first fixing bracket 7 and the second fixing bracket 8 are hinged through the rotating shaft 9, A friction plate 10 is arranged between the first fixed bracket 7 and the second fixed bracket 8. The friction plate 10 is fixed by bolts, and the tightness can be adjusted. In this embodiment, the number of friction plates 10 is four. The number of sheets 10 may be two or six.

[0034] The sliding mechanism 4 is arranged between the base plate 3 and the sliding plate 2. The sliding mechanism 4 includes a sliding rail 41 fixed ...

Embodiment 2

[0041] The structure and principle of this embodiment are basically the same as those of the first embodiment. The difference is that in this embodiment, the lifting mechanism 5 includes four first lifting rods fixed on the bottom of the panel 1 and four first lifting rods fixed on the top of the sliding plate 2. Four second lifting rods, the first lifting rod and the second lifting rod are arranged in parallel, and the first lifting rod and the corresponding second lifting rod are attached, and the side of the second lifting rod close to the first lifting rod has six The second positioning hole, the first lifting rod is provided with elastic parts such as cylindrical springs and steel balls. In actual production, the number of the first lifting rod and the second lifting rod can be six or eight, and the number of the second positioning holes There may be four or eight, and the elastic member may be a conical spring. Pull the panel 1 upward, the first lifting rod moves upward,...

Embodiment 3

[0043] The structure and principle of this embodiment are basically the same as those of the first embodiment. The difference is that, in this embodiment, the sliding mechanism 4 includes a sliding rail 41 fixed on the base plate 3 and a slider fixed on the sliding plate 2. The sliding block and the sliding rail 41 are matched with zero clearance through the dovetail groove structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com