A high-safety installation bracket for lightning protection equipment

A mounting bracket and safety technology, which is applied in the field of lightning protection equipment mounting brackets, can solve problems such as threats to safety, open circuits, and difficulty in effectively promoting the connection strength of lightning rod contacts, so as to achieve the effect of improving safety and high security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

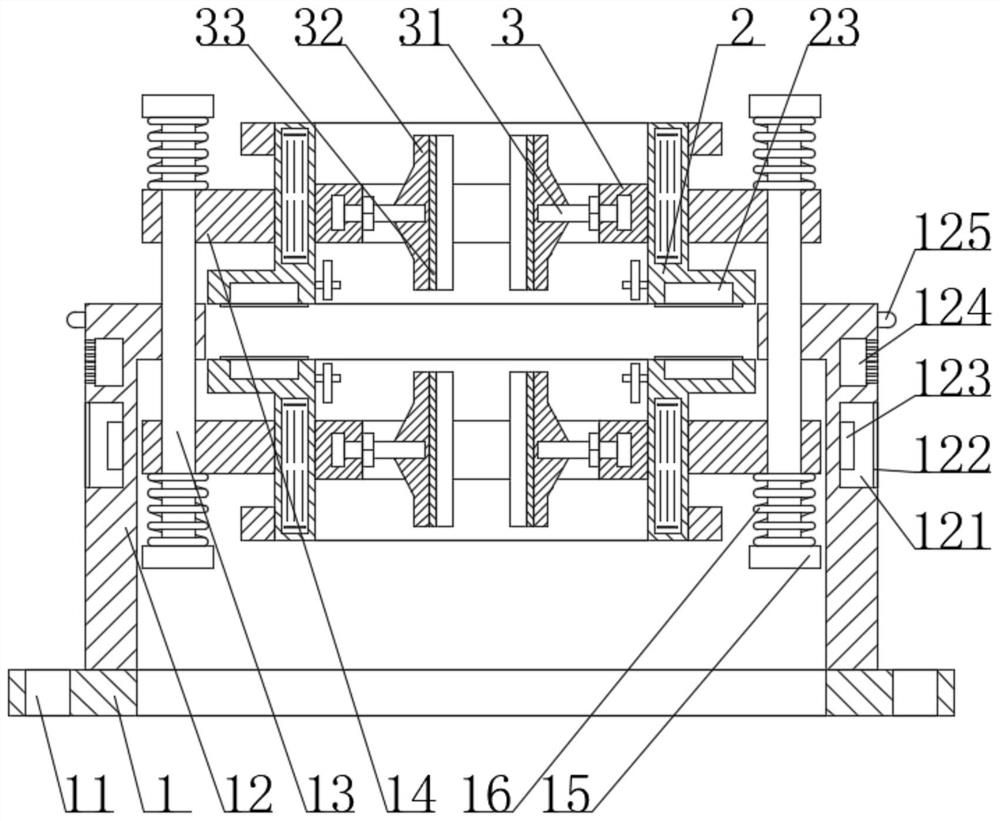

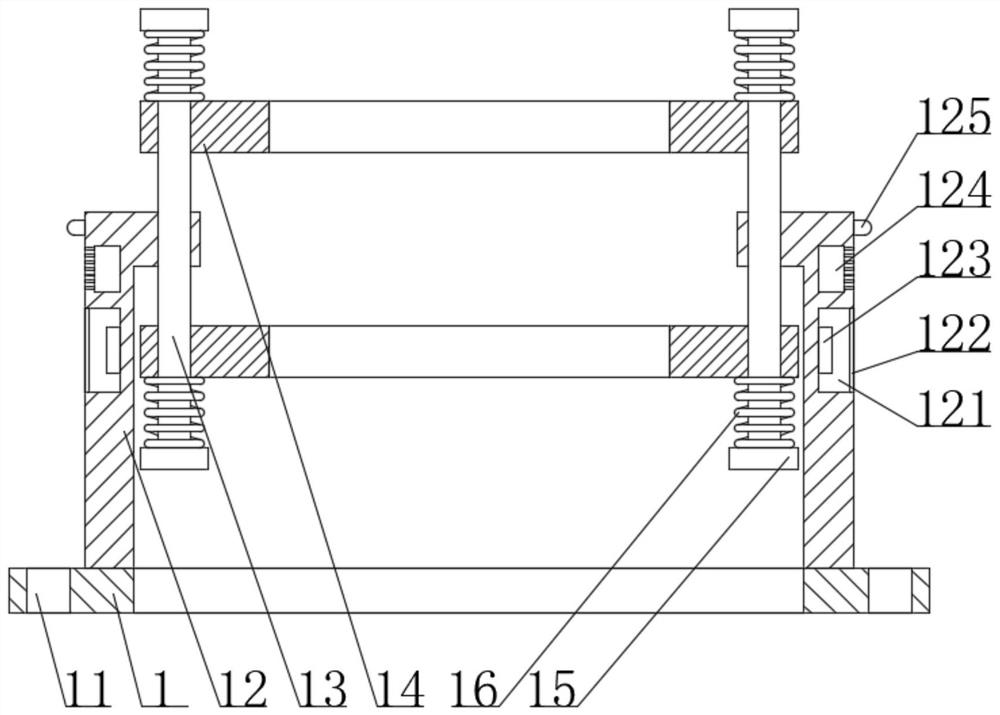

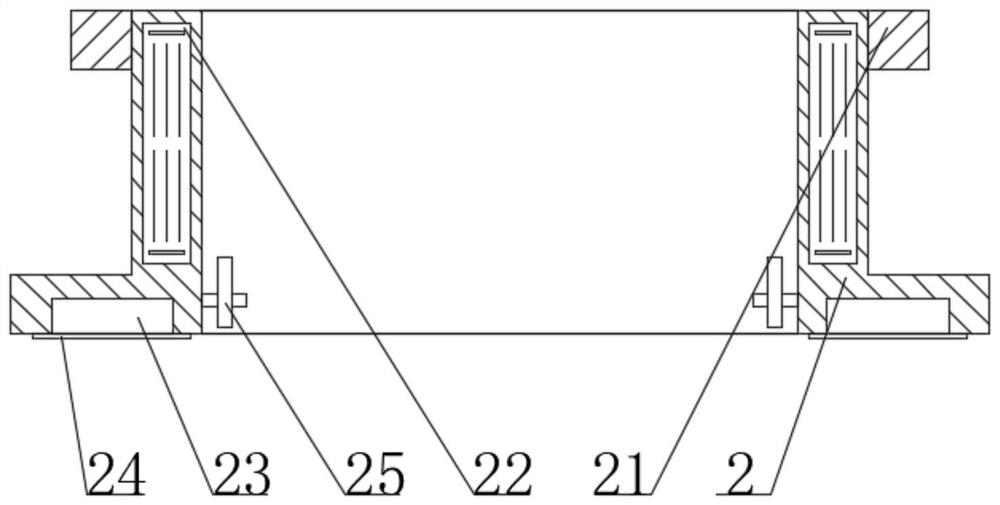

[0025] see Figure 1-5 , the present invention provides a technical solution: a mounting bracket for lightning protection equipment with high safety, comprising a base 1 and a fixing frame 2, the base 1 is in a ring structure, and the surrounding edges of the upper surface of the base 1 are provided with There are threaded holes 11, and the bottom ends of the threaded holes 11 all run through the base 1. Through the threaded holes 11, it is convenient for users to install and fix the base 1 on the ground or building where the lightning protection equipment, that is, the periphery of the lightning rod, is located. Both ends of the upper surface of the base 1 The support frame 12 is fixedly connected with the support frame 12 by bolts. The support frame 12 has an L-shaped structure. The middle part of the outer periphery of the support frame 12 is provided with an installation groove 121 near the top end. The installation groove 121 has a rectangular structure. A cover plate 122...

Embodiment 2

[0029] see Figure 1-5 , the present invention provides a technical solution: a mounting bracket for lightning protection equipment with high safety, comprising a base 1 and a fixing frame 2, the base 1 is in a ring structure, and the surrounding edges of the upper surface of the base 1 are provided with There are threaded holes 11, and the bottom ends of the threaded holes 11 all run through the base 1. Through the threaded holes 11, it is convenient for users to install and fix the base 1 on the ground or building where the lightning protection equipment, that is, the periphery of the lightning rod, is located. Both ends of the upper surface of the base 1 The support frame 12 is fixedly connected with the support frame 12 by bolts. The support frame 12 has an L-shaped structure. The middle part of the outer periphery of the support frame 12 is provided with an installation groove 121 near the top end. The installation groove 121 has a rectangular structure. A cover plate 122...

Embodiment 3

[0033] see Figure 1-5 , the present invention provides a technical solution: a mounting bracket for lightning protection equipment with high safety, comprising a base 1 and a fixing frame 2, the base 1 is in a ring structure, and the surrounding edges of the upper surface of the base 1 are provided with There are threaded holes 11, and the bottom ends of the threaded holes 11 all run through the base 1. Through the threaded holes 11, it is convenient for users to install and fix the base 1 on the ground or building where the lightning protection equipment, that is, the periphery of the lightning rod, is located. Both ends of the upper surface of the base 1 The support frame 12 is fixedly connected with the support frame 12 by bolts. The support frame 12 has an L-shaped structure. The middle part of the outer periphery of the support frame 12 is provided with an installation groove 121 near the top end. The installation groove 121 has a rectangular structure. A cover plate 122...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com