Automatic PT cabinet switching device for multipath incoming lines

An automatic switching and incoming line technology, applied in circuit devices, busbar/line layout, substation/distribution device housing, etc., can solve the problem of untimely circuit disconnection, unsecured safety, and multi-channel incoming PT cabinets. Unable to automatically switch and other problems to achieve the effect of improving reliability and ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

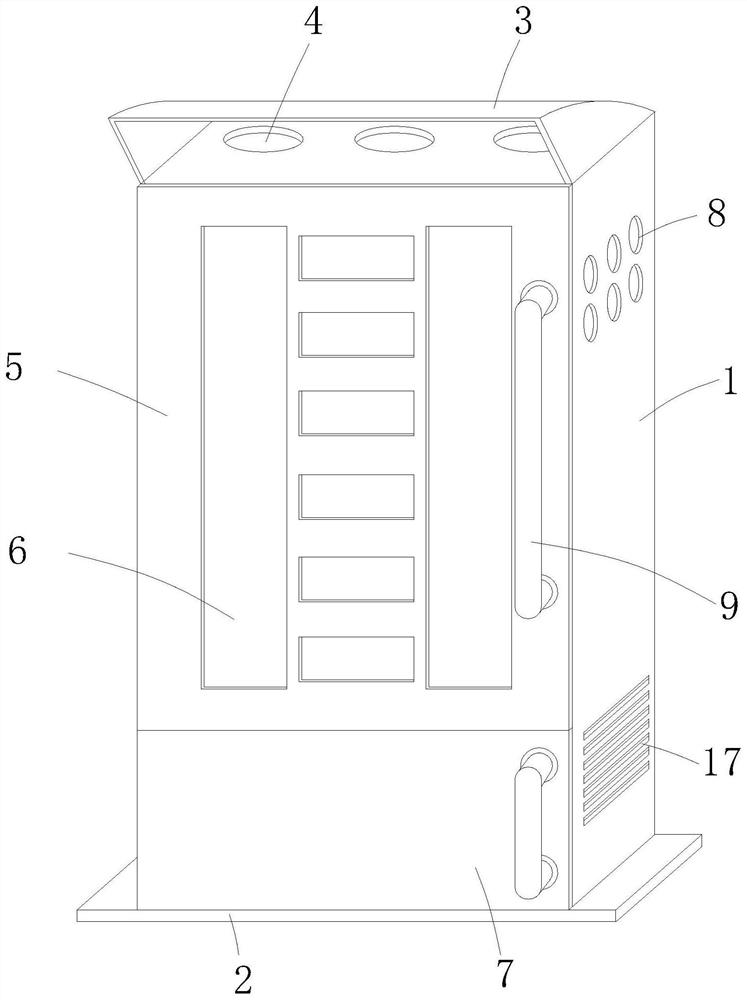

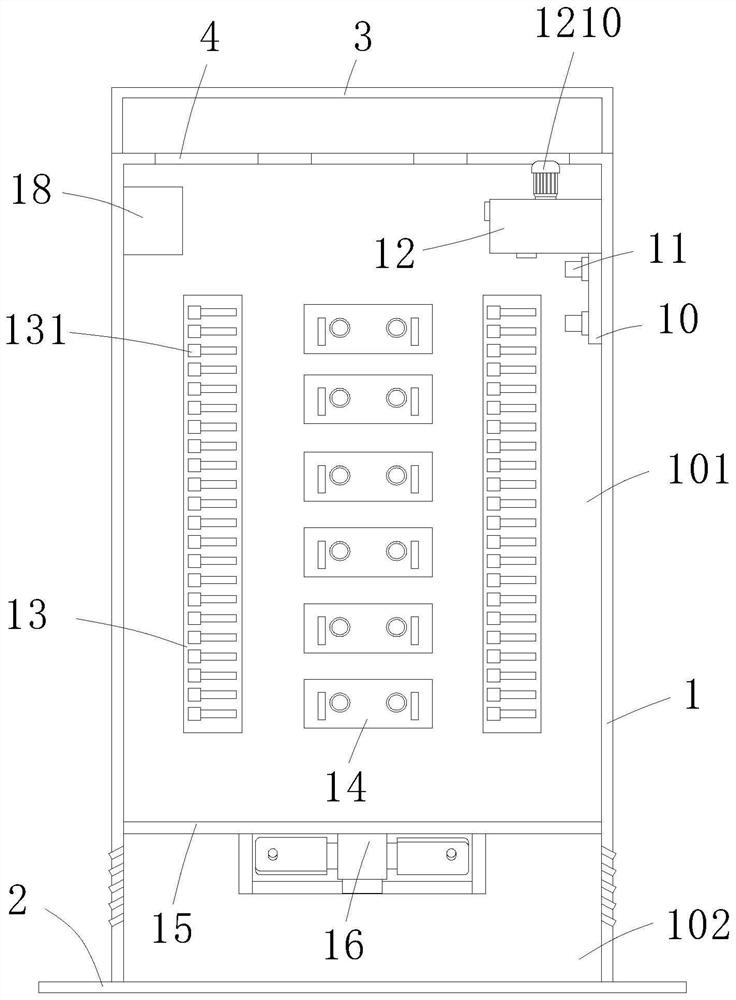

[0031] A PT cabinet automatic switching device for multiple incoming lines, comprising a hollow cabinet body 1 and a base 2 installed at the lower end of the cabinet body 1, the lower part of the inner cavity of the cabinet body 1 is horizontally equipped with a porous partition plate 15, and the porous The partition plate 15 divides the inner cavity of the cabinet body 1 from top to bottom into an installation cavity 101 and a heat dissipation cavity 102. The front wall of the cabinet body 1 corresponding to the positions of the installation cavity 101 and the heat dissipation cavity 102 is respectively provided with an upper cabinet door 5 and a Lower cabinet door 7;

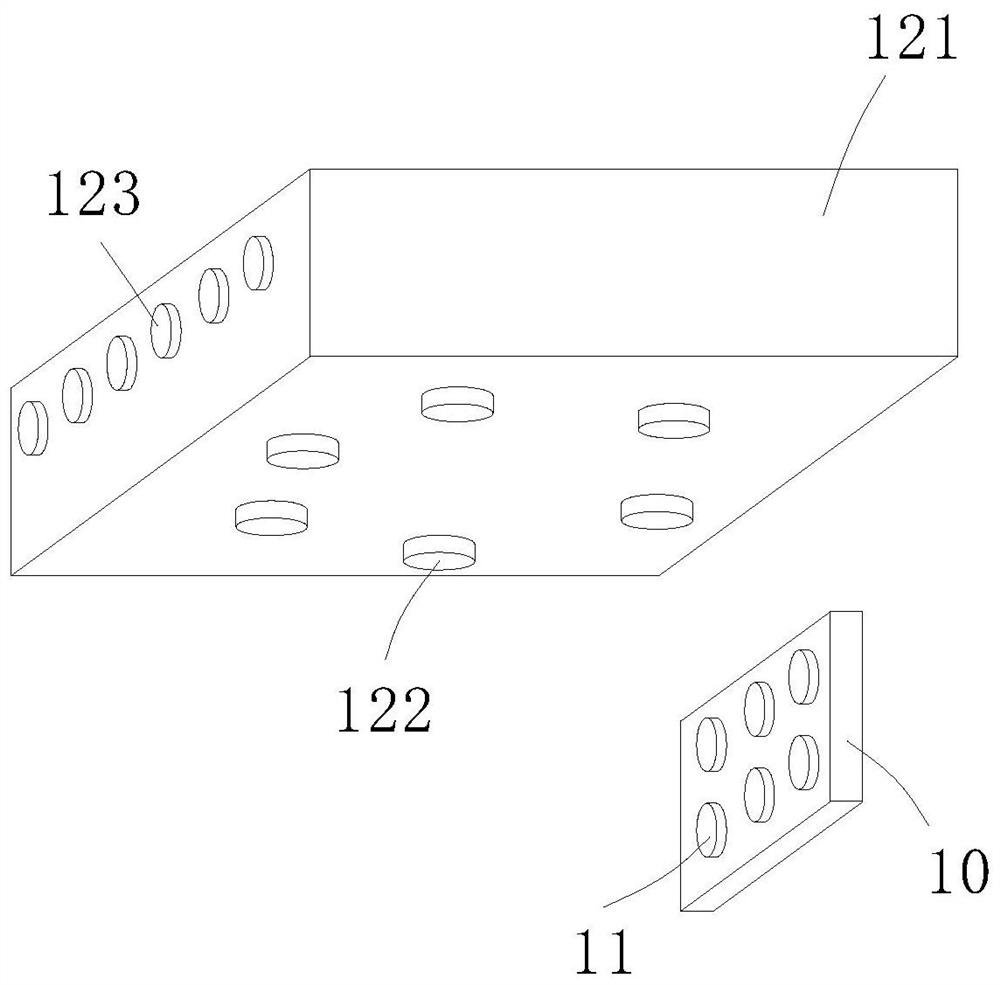

[0032] In this example, if Figure 1-2 As shown, on the side wall of the cabinet body 1 corresponding to the position of the installation cavity 101, there are a plurality of inlets 8 for multiple incoming lines to pass through, and a terminal block 10 is installed on the inner wall of the installation cavity ...

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is that, as Figure 1-2 As shown, a plurality of exhaust outlets 4 are provided on the top wall of the cabinet body 1, and an air intake grid 17 is provided on the side wall of the cabinet body 1 corresponding to the position of the cooling chamber 102, and an inner cavity of the cooling chamber 102 is provided with There is a heat dissipation fan 16 with the output end facing upwards. The air inlet grid 17 is provided with two groups and is respectively symmetrically embedded on the opposite side walls of the cabinet 1 to ensure the cooling of the air intake. The grid is arranged downwards from the inside to the outside to prevent external rainwater from entering the inner cavity of the cabinet body 1. A ceiling 3 with a front opening is installed on the top wall of the cabinet body 1, and the ceiling 3 is inclined from the front to the rear. Downward setting prevents external rainwater from entering the inner cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com