A flexible direct current transmission system and its direct current fault handling method

A power transmission system, flexible direct current technology, applied in the field of flexible power transmission and distribution, can solve problems such as capacitor voltage overvoltage and diode overcurrent, and achieve the effect of solving overvoltage and overcurrent with simple and effective structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail below in conjunction with accompanying drawing:

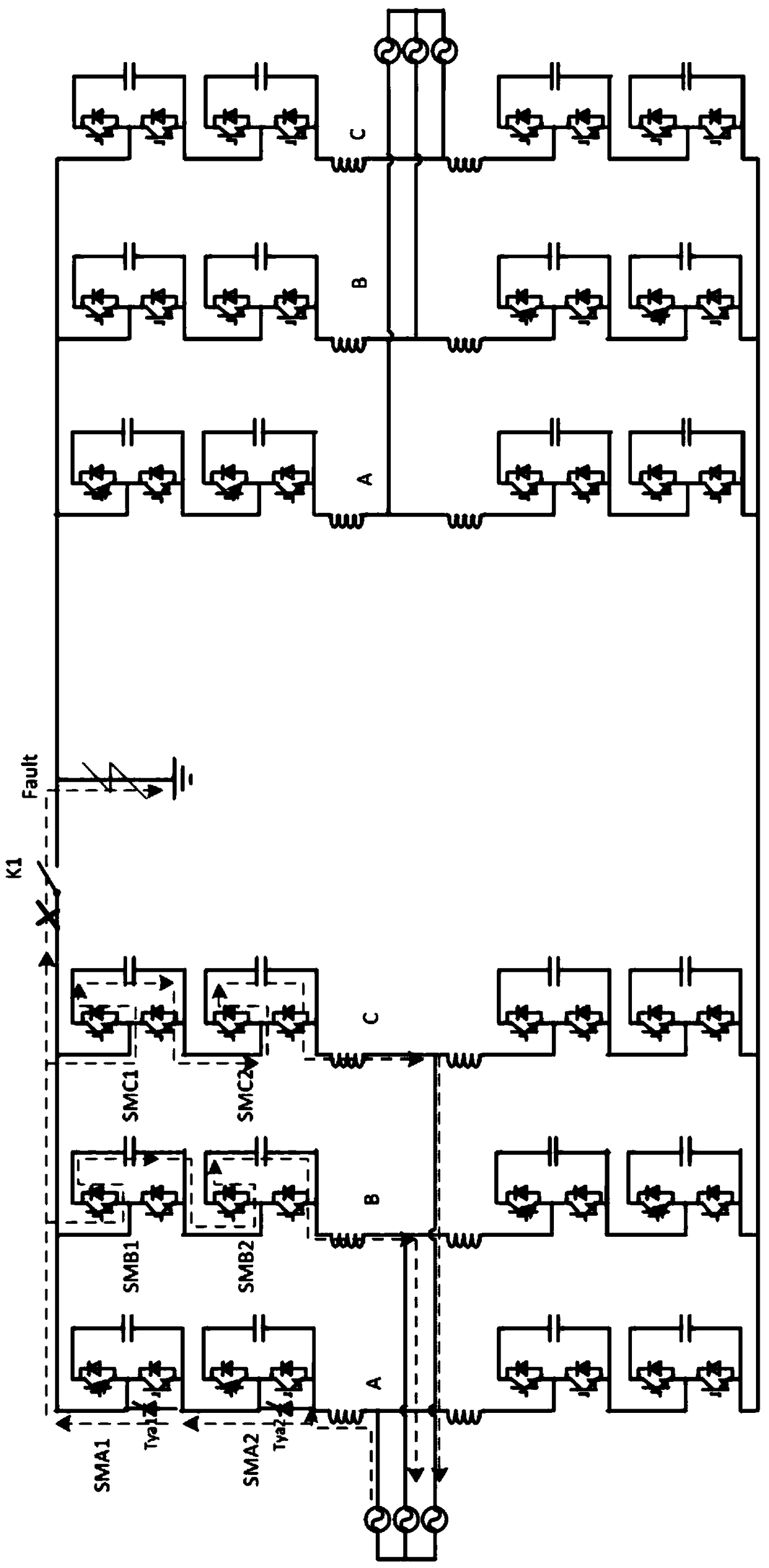

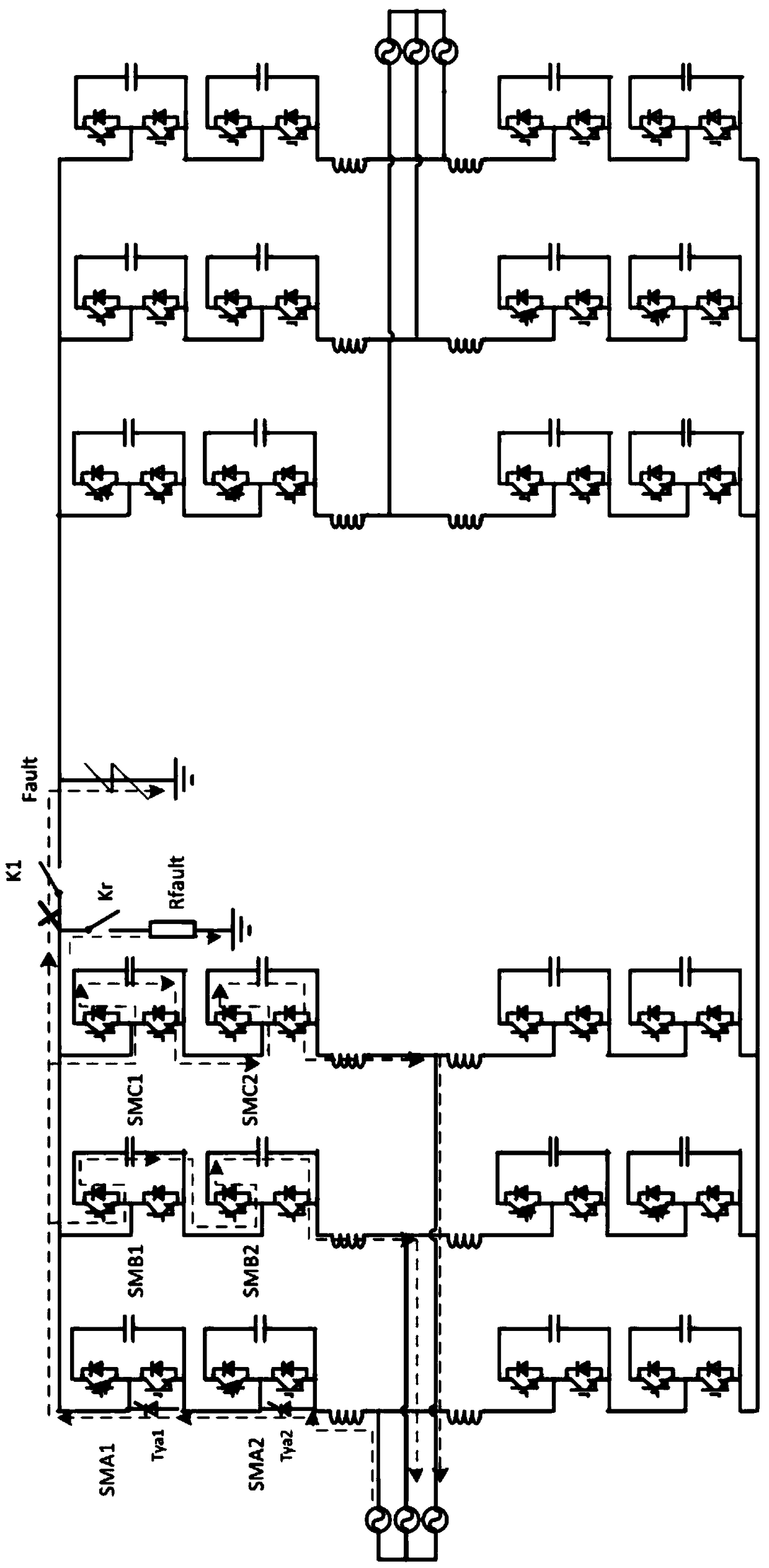

[0035] Such as image 3 As shown, a flexible direct current transmission system includes three-phase converter valves A, B, and C, wherein each phase converter valve is divided into an upper bridge arm and a lower bridge arm, and the upper bridge arm and the lower bridge arm are respectively composed of several The sub-modules are cascaded; the power transmission system composed of A, B, and C three-phase converter valves is connected to the AC power grid on one side, and the other side is connected to the DC overhead line. The power transmission system composed of A, B, and C three-phase converter valves There is a discharge resistor R connected between the system and the DC overhead line, and the discharge resistor R is connected to the system through the switch Kr; if image 3As shown, the left and right sides of the flexible DC transmission system are connected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com