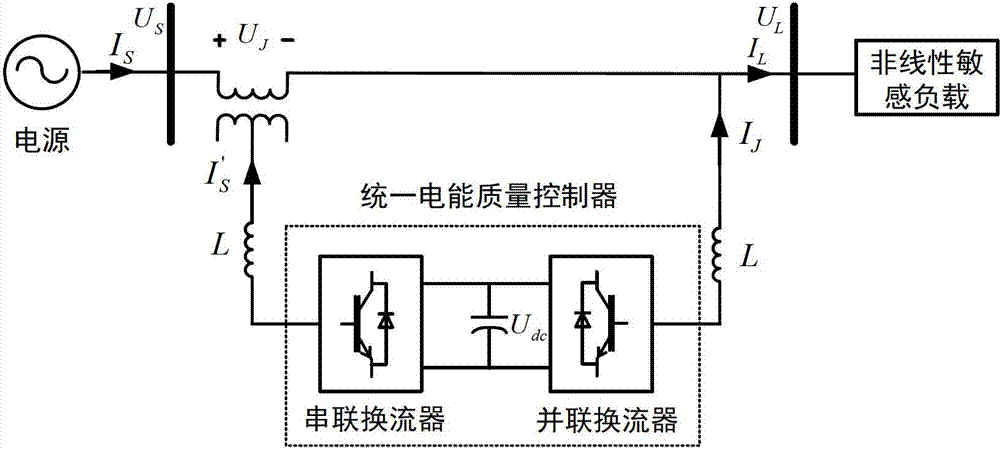

Voltage dip compensation method of unified power quality conditioner with zero input active power

A technology of power quality and voltage sag, applied in the direction of reactive power adjustment/elimination/compensation, reactive power compensation, AC network voltage adjustment, etc., can solve limited effects, uncertain compensation duration recovery and restart, system voltage sag And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

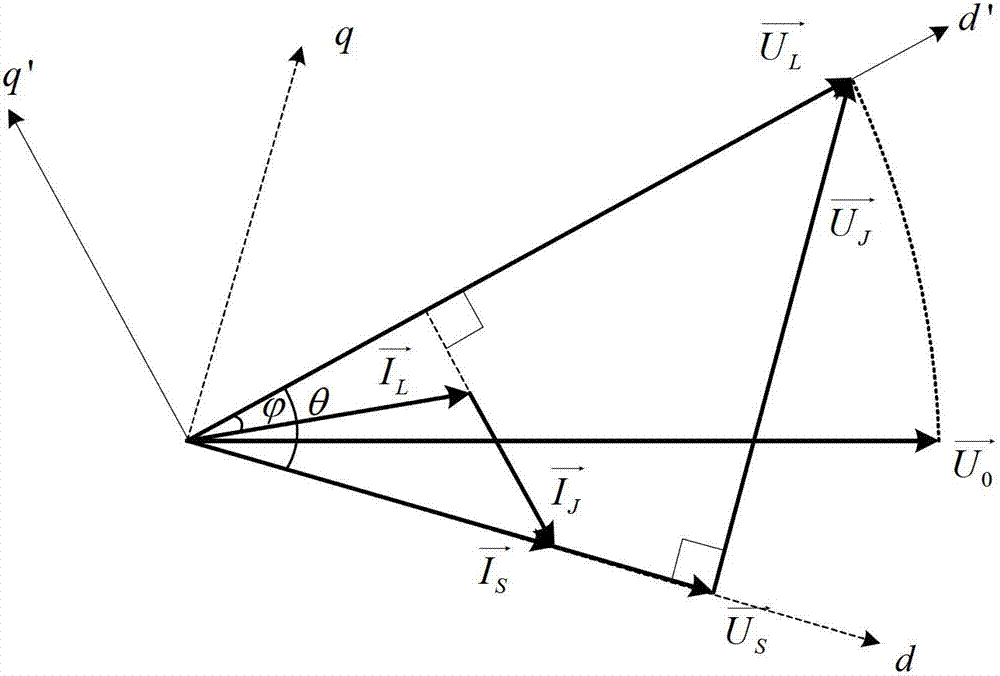

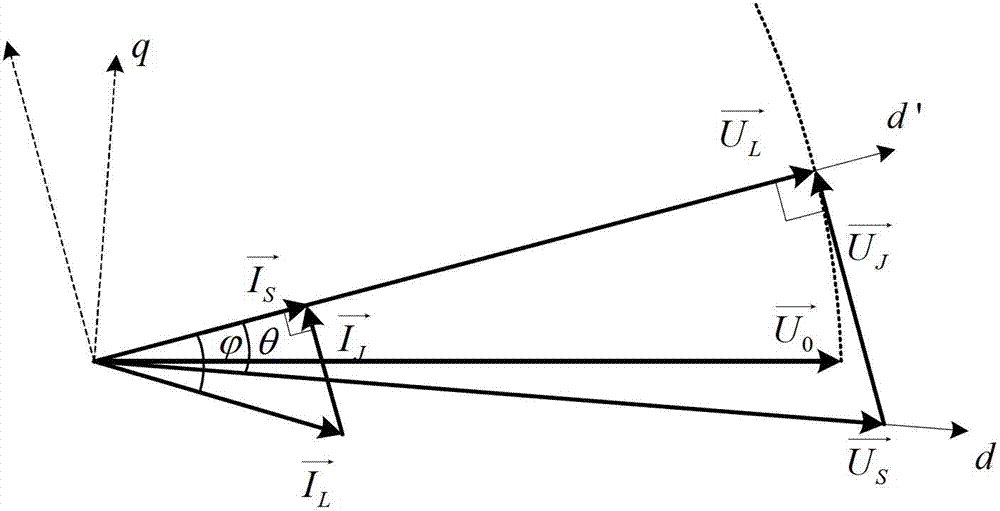

[0037] figure 2 Shown is the vector diagram of the voltage sag compensation strategy for the unified power quality controller (UPQC) with zero active power injection. in, is the system voltage vector before the sag, is the system voltage vector after the sag occurs, is the load voltage vector after compensation, Inject a voltage vector for the series side of the UPQC, is the load current vector, is the system current vector, Inject the current vector for the parallel side of the UPQC. Such as figure 2 As shown, when a voltage sag occurs in the system, the UPQC series part injects into the system a compensation voltage vector that is ahead and perpendicular to the system voltage vector. At the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com