Binding tool

A technique of utensils and postures, which is applied in the field of binding utensils and can solve the problems of constraints of binding utensils, large size of binding utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In the following description, for convenience of description, the side of the binding tool T, such as a binding paper, is referred to as the front side, and the opposite side is referred to as the rear side.

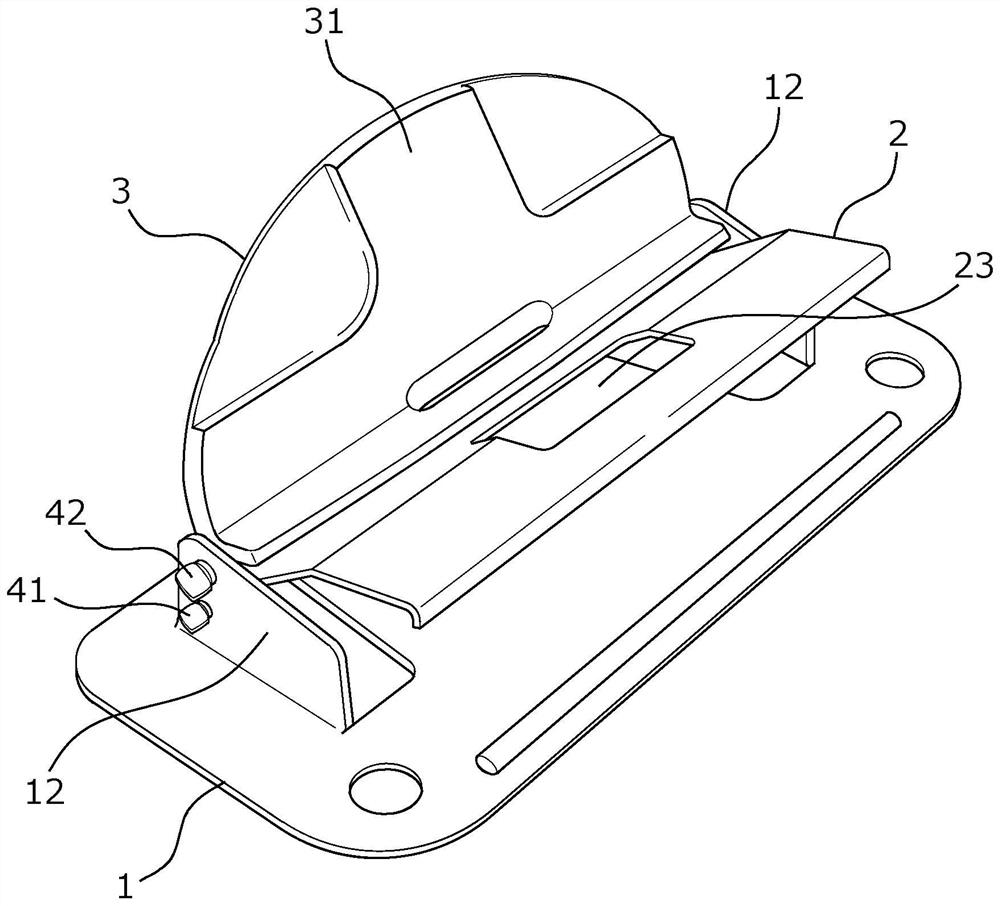

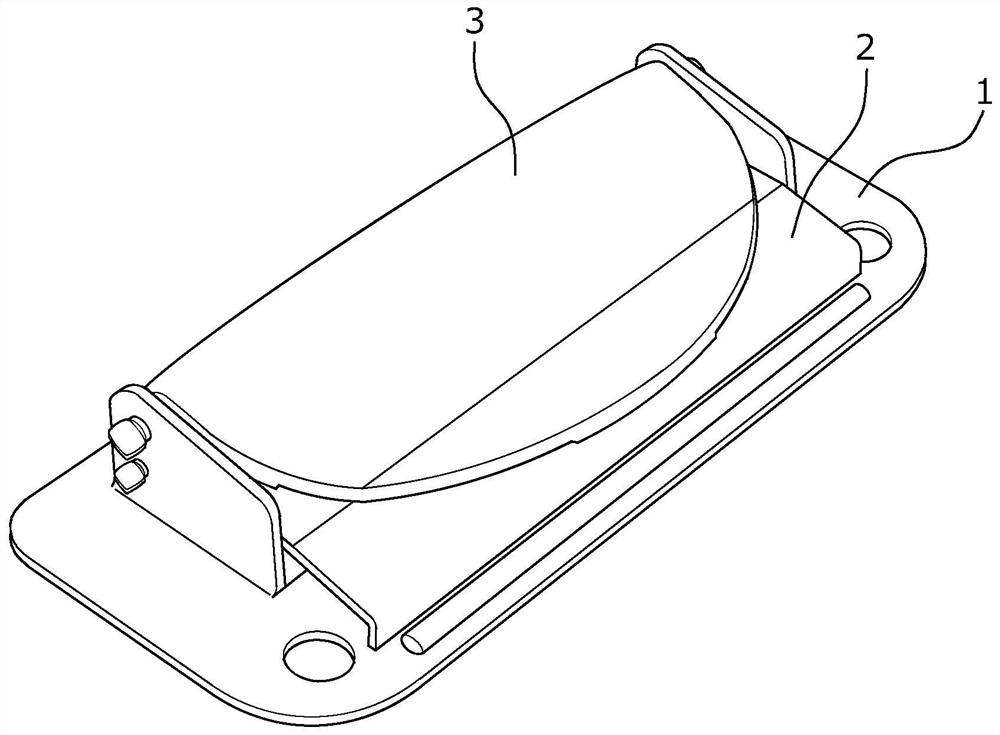

[0040] Such as figure 1 As shown, the binding tool T of the present embodiment mainly has a base 1, a clamping part 2, an operating part 3, a first rotating shaft 41, a second rotating shaft 42 and a spring 43 (refer to Figure 10 , Figure 11 ).

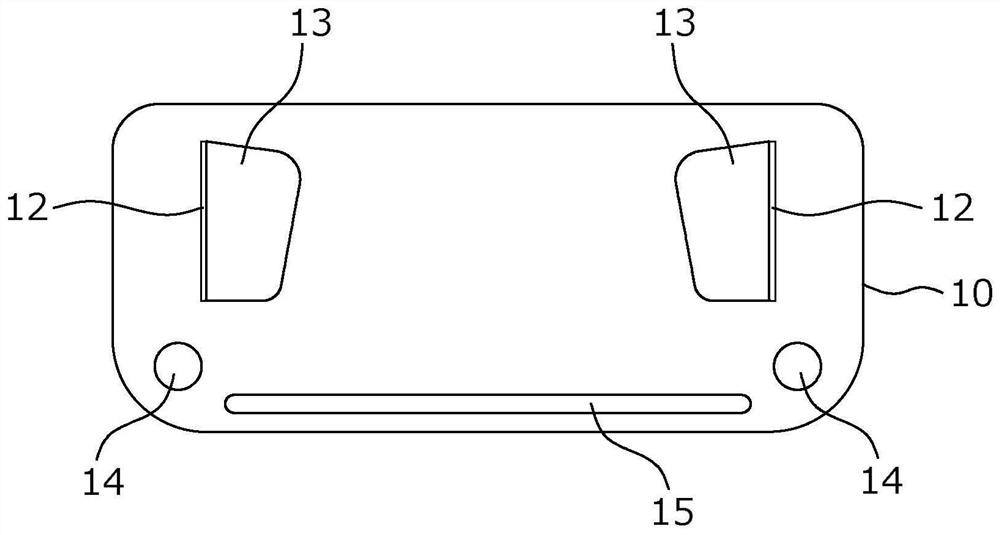

[0041] The base 1 is formed by punching a sheet metal. Such as image 3 and Figure 4 As shown, the base 1 is generally rectangular in plan view, and the four corners are rounded. The base 1 has a rectangular base main body 10 in plan view, and two supporting parts 12 parallel to each other and perpendicular to the base main body 10 . The two support portions 12 are formed by punching the base body p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com