Airtight performance keeping design method based on full life cycle

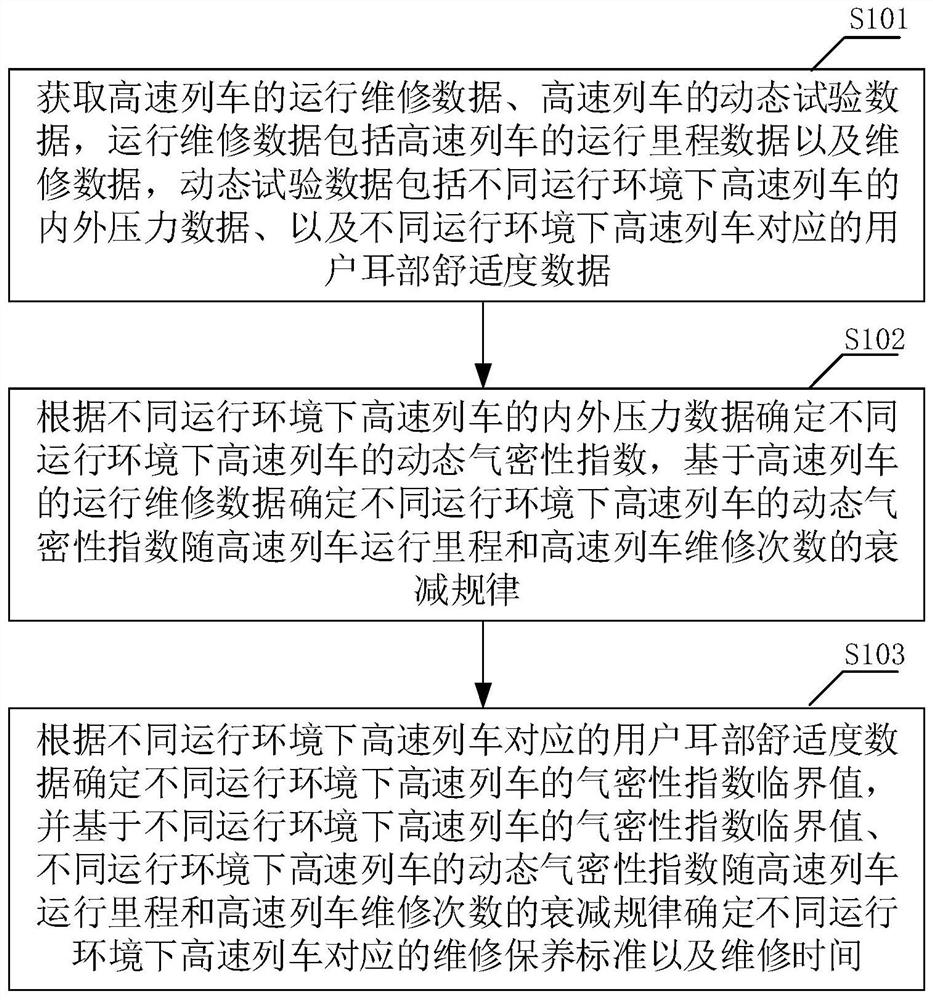

A technology with a full life cycle and a design method, applied in the field of airtight performance maintenance based on the full life cycle, can solve the problems of inability to effectively guarantee the airtight performance of high-speed trains and inaccurate judgment methods, so as to achieve accurate judgment and maintain airtightness. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0051] Optionally, as a specific implementation of the design method for maintaining airtight performance based on the full life cycle provided in the embodiment of the present invention, the design method for maintaining airtight performance based on the full life cycle further includes:

[0052] Based on the critical value of the air tightness index of the high-speed train under different operating environments, it is judged whether the air tightness index of the high-speed train after maintenance reaches the preset air tightness standard.

[0053] Optionally, as a specific implementation of the airtight performance maintenance design method based on the full life cycle provided by the embodiment of the present invention, the overall performance of the high-speed train after overhaul is judged based on the critical value of the air-tightness index of the high-speed train under different operating environments. Whether the airtightness index of the vehicle reaches the preset a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com