Preparation method of FPC board

A core board and substrate technology, applied in the field of FPC board preparation, can solve the problems of product electrical performance risk, consistency mismatch, increase product thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

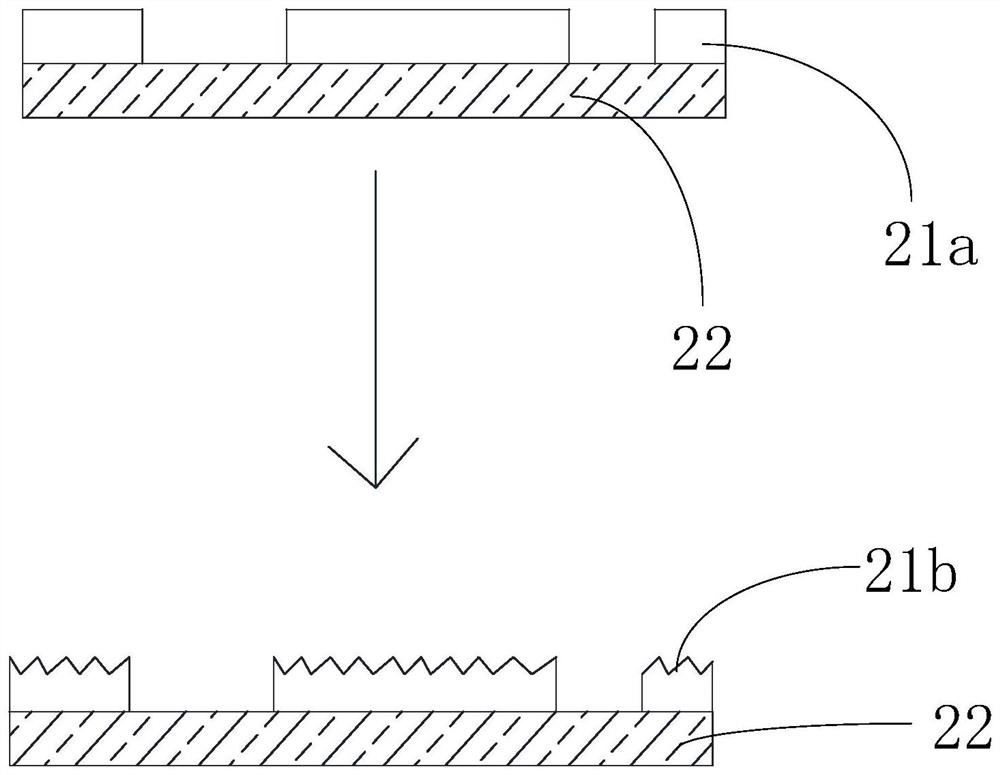

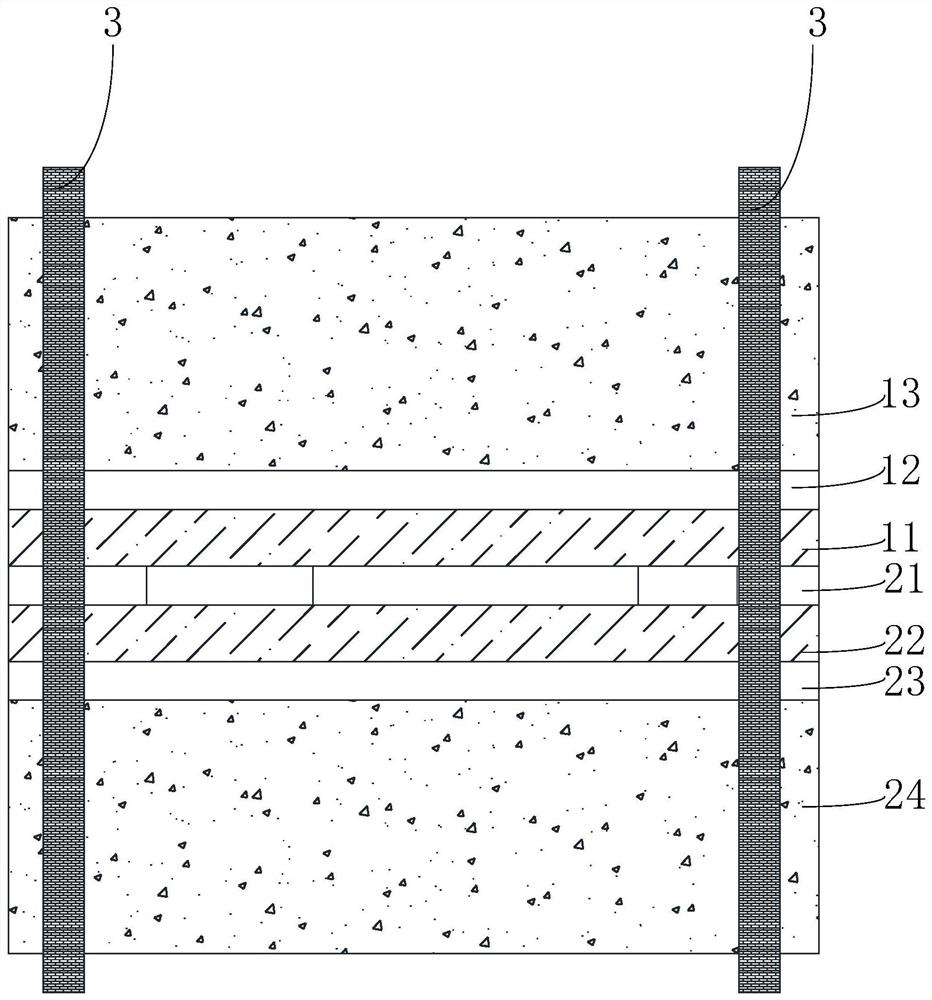

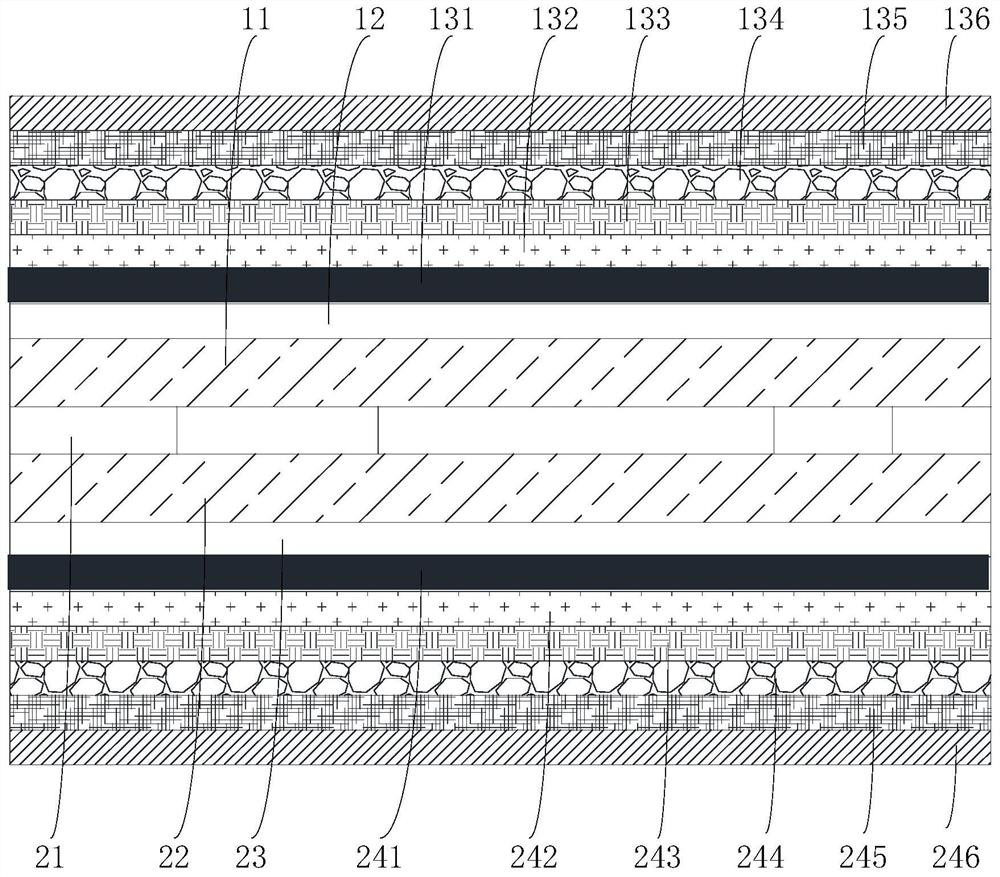

[0026] refer to Figure 1-4 , an embodiment of the present invention provides a method for preparing an FPC board. The first core board 10 and the second core board 20 are pressed together. The first core board 10 includes a first copper layer 12 and a first dielectric layer 11 arranged in sequence. , the second core board 20 includes a second copper layer 23, a second dielectric layer 22 and an inner circuit layer 21 arranged in sequence. After lamination, the inner circuit layer 21 is located between the first dielectric layer 11 and the second dielectric layer. Between the layers 22, the FPC board obtained after lamination includes the first copper layer 12, the first dielec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com