Withdrawal and straightening machine for washing machine drum manufacturing

A technology of washing machine drum and tension leveler, applied in the field of tension leveler, can solve the problems of cumbersome leveling process, long leveling time for iron sheets in the inner drum of the washing machine, different specifications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

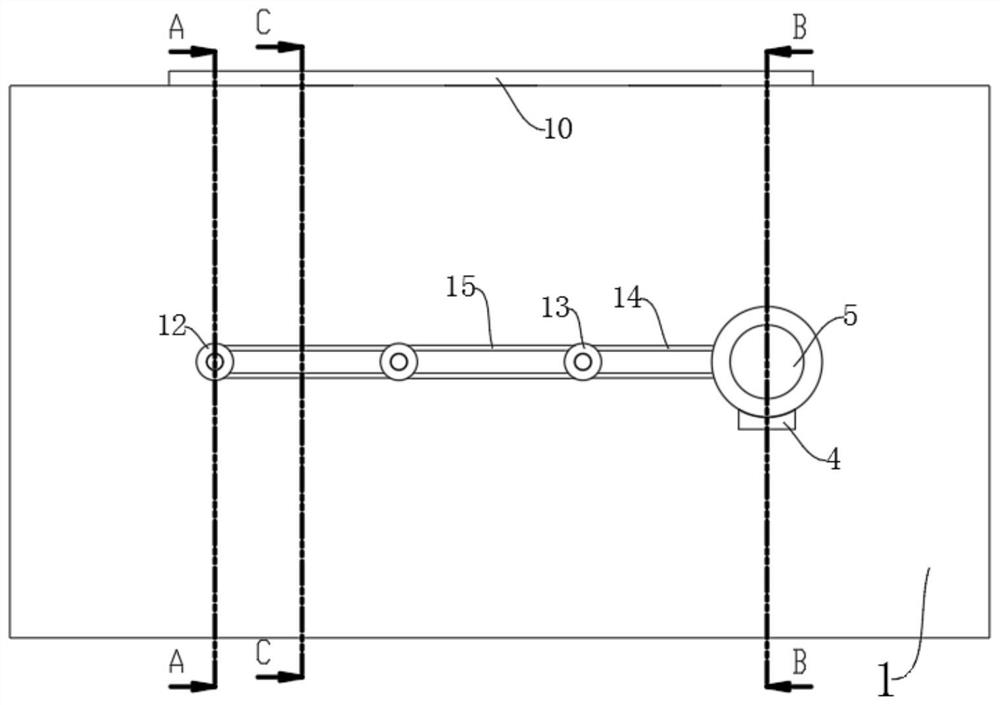

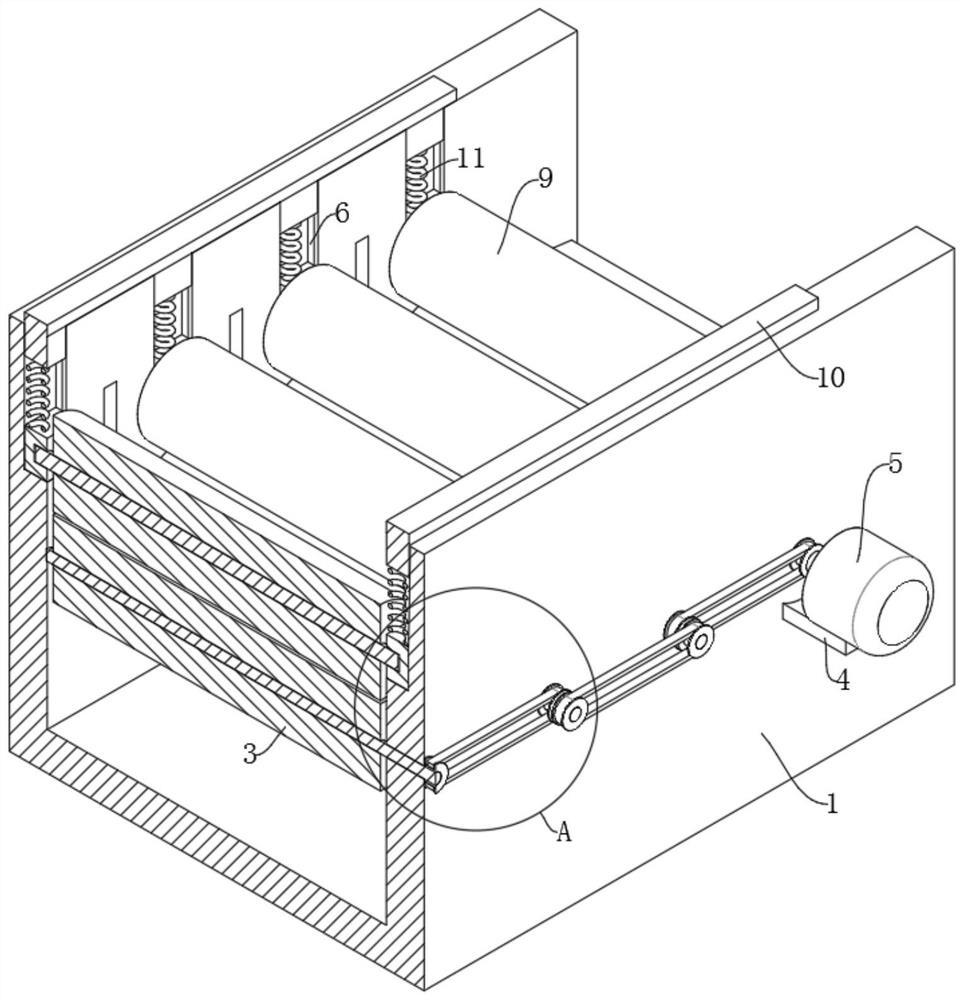

[0025] refer to Figure 1-7 , a tension leveling machine for washing machine drum preparation, comprising a support seat 1, a plurality of first rotating shafts 2 are placed on one side of the bearing seat 1, the plurality of first rotating shafts 2 is set to four, and the plurality of first rotating shafts 2 are each Through the bearing through the support base 1, the first rolling rollers 3 are installed on the multiple first rotating shafts 2 inside the support base 1, the multiple first rolling rollers 3 are set to four, and the motor base 4 is installed on one side of the support base 1 , a motor 5 is installed on the motor base 4 (the end of the support base 1 close to the motor 5 is the feed port), the output shaft of the motor 5 is connected with one of the first rotating shafts 2, and a plurality of first rotating shafts 2 are connected by a transmission mechanism. Connection; base 1 bottom is provided with a plurality of chute 6, and a plurality of chute 6 is set to ...

Embodiment 2

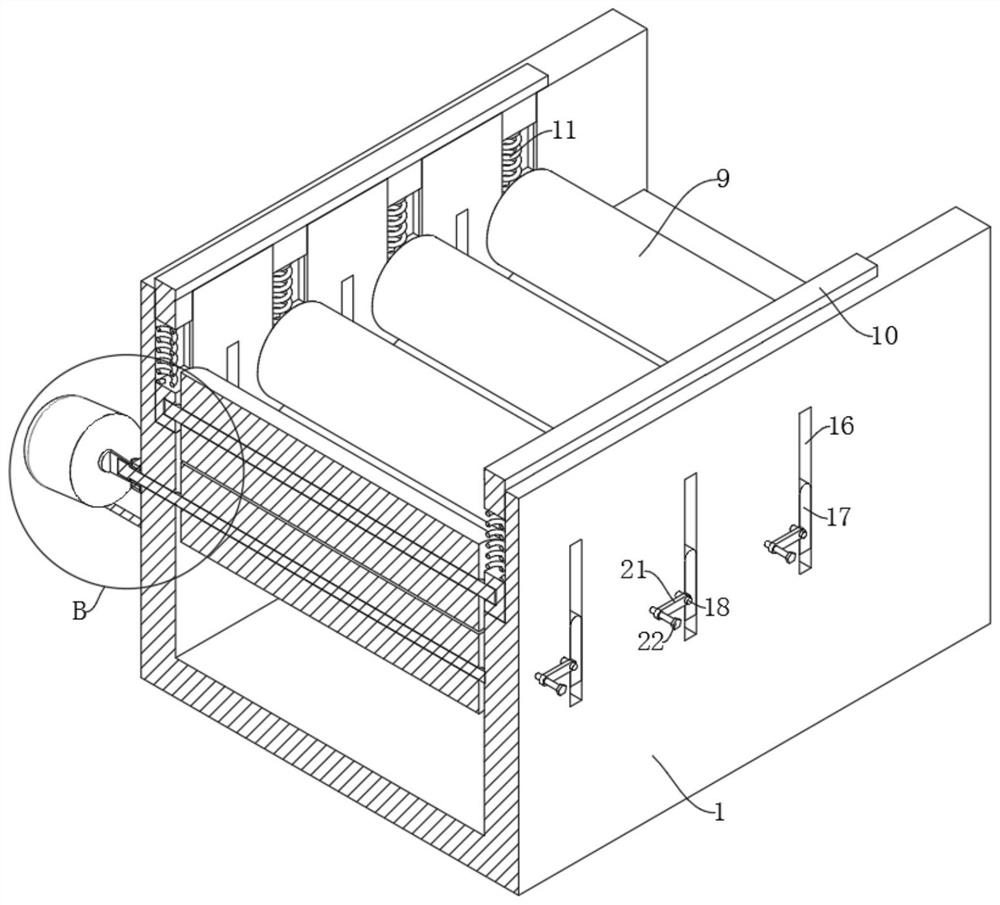

[0028] refer to Figure 1-7 The supporting seat 1 is provided with three grooves 16 on the side away from the motor 5, and the three grooves 16 are arranged at intervals, and a partition 17 is slidably arranged in the three grooves 16, and the supporting seat 1 is close to the three grooves 16- The third rotating shaft 18 is placed on each side, and the three third rotating shafts 18 all pass through the support seat 1 through bearings and are equipped with two gears 19. The two gears 19 on the third rotating shaft 18 are arranged at intervals, and three partitions 17 is equipped with a rack 20 near the side of the gear 19, and a plurality of racks 20 are meshed with a plurality of gears 19, and the three third rotating shafts 18 on the outside of the support base 1 are equipped with connecting blocks 21, three There are pins 22 placed on the side of the connecting block 21 away from the support base 1, and the three pins 22 are threaded through the connecting block 21 and abu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com