Multi-environment independent control method and system for ultra-high precision laboratories

An independently controlled, laboratory technology for use in clean laboratories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

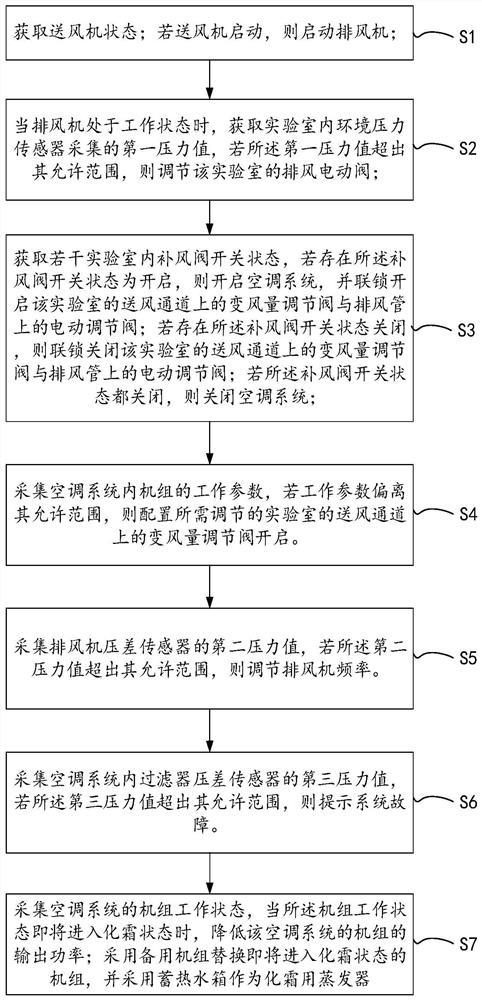

[0034] The invention discloses a multi-environment independent control method for an ultra-high-precision laboratory, such as figure 1 shown, including the following steps:

[0035] S1. Obtain the status of the air blower; if the air blower starts, start the exhaust fan;

[0036] S2. When the exhaust fan is in the working state, obtain the first pressure value collected by the ambient pressure sensor in the laboratory, and if the first pressure value exceeds its allowable range, adjust the electric exhaust valve of the laboratory;

[0037] S3. Obtain the switch status of the supplementary air valve in several laboratories. If the switch status of the supplementary air valve is open, turn on the air conditioning system and interlock the variable air volume control valve and exhaust air on the air supply channel of the laboratory. The electric regulating valve on the pipe; if the switch state of the supplementary air valve is closed, the variable air volume regulating valve on ...

Embodiment 2

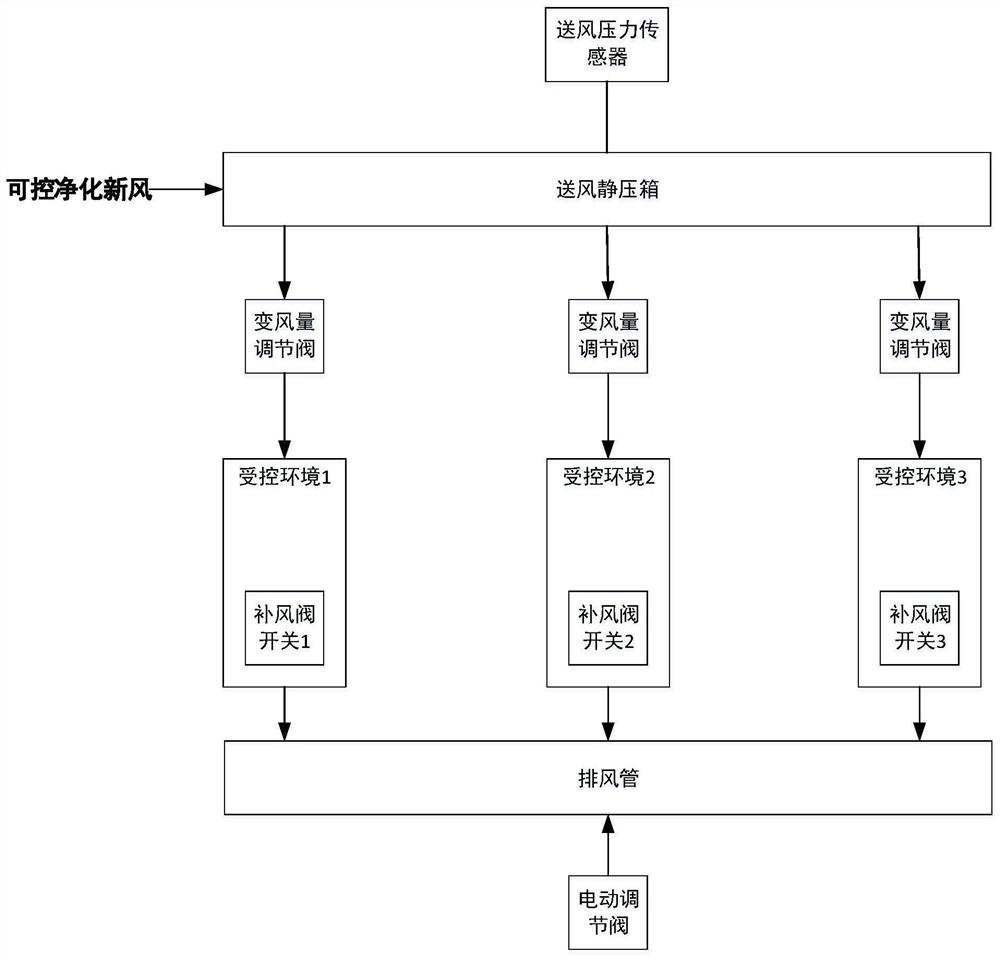

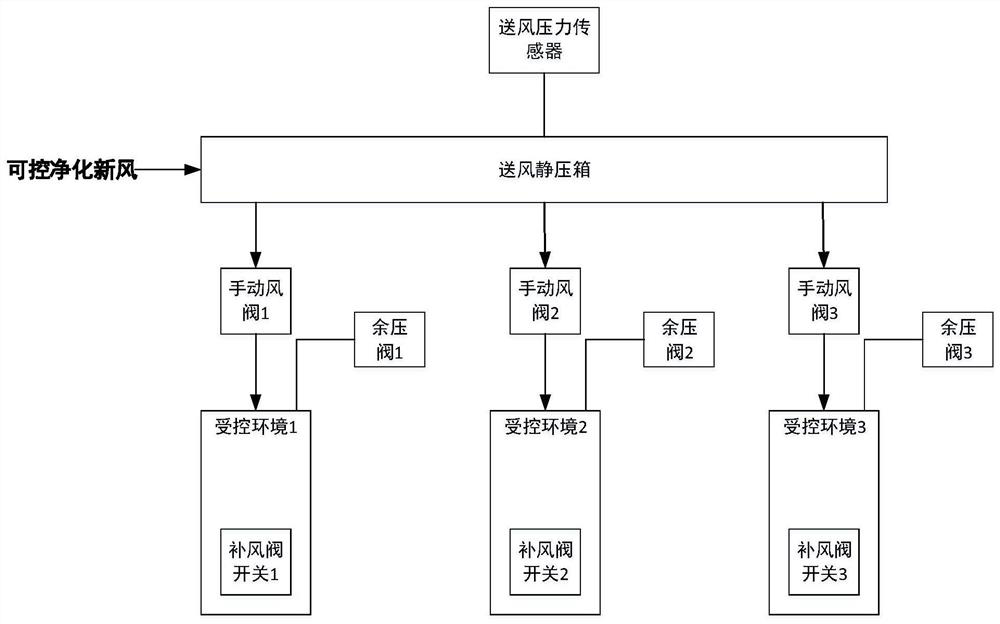

[0046] The present invention also provides the multi-environment independent control system of the ultra-high precision laboratory, such as Figure 2-4 As shown, it includes a fresh air system 10, an air conditioning system, an air supply channel, an exhaust pipe, a controller, and a supplementary air valve switch; one end of the air conditioning system is connected to the fresh air system, and the other end is connected to the air supply channel; the air supply channel Connect several laboratories to provide controllable and purified fresh air; each of the laboratories is connected to an exhaust pipe for exhaust; wherein,

[0047] The air supply channel of each laboratory is provided with a variable air volume regulating valve; each laboratory is equipped with a make-up air valve switch, and an electric regulating valve on the exhaust pipe; the controller is configured to execute the The multi-environment independent control method of the ultra-high precision laboratory descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com