Motor stator and motor

A technology of motor stator and motor rotor, applied in the field of motor and motor stator, can solve the problems of low full rate of stator slots, low material utilization rate, weakening torque ripple, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

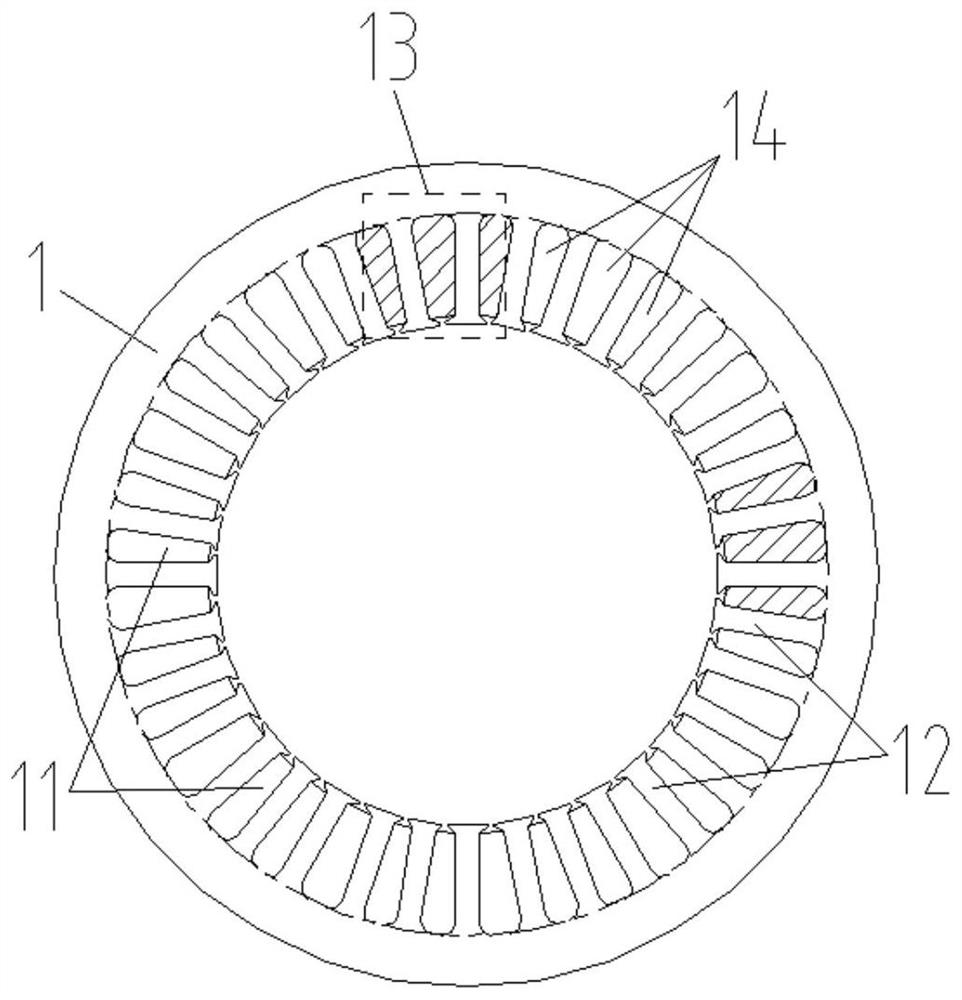

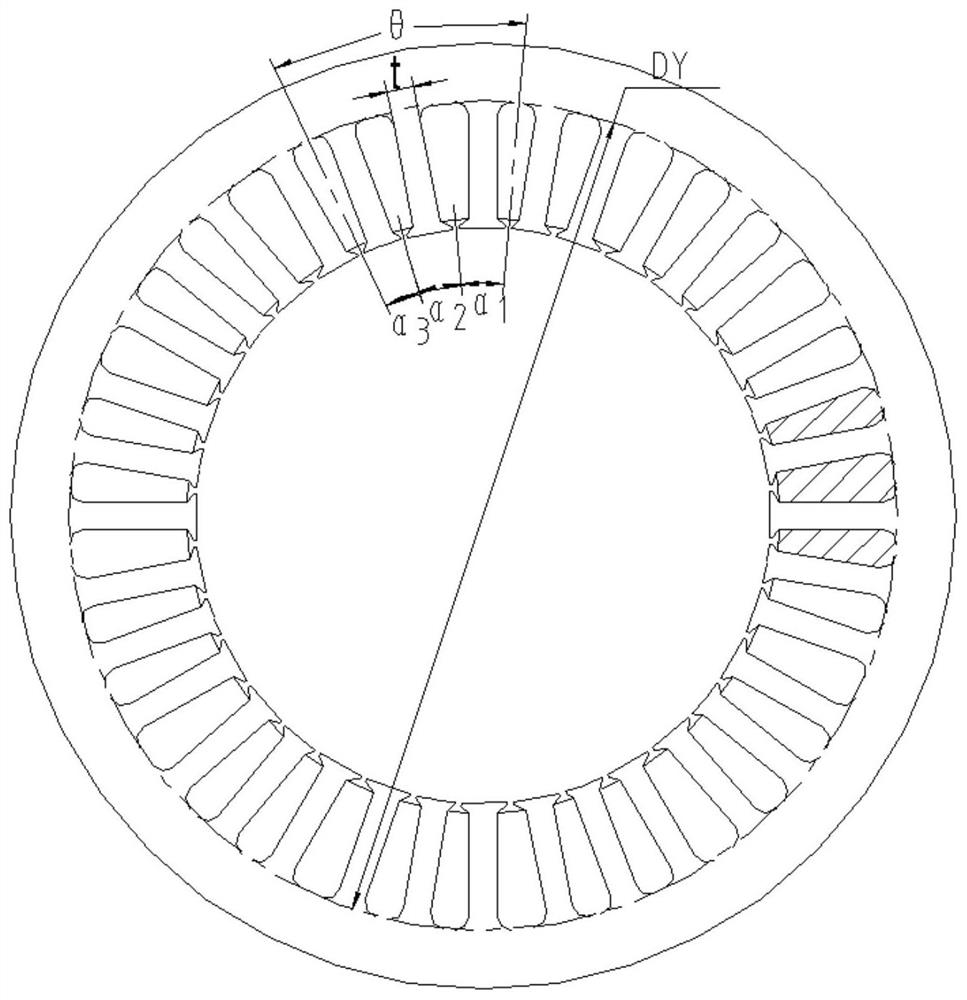

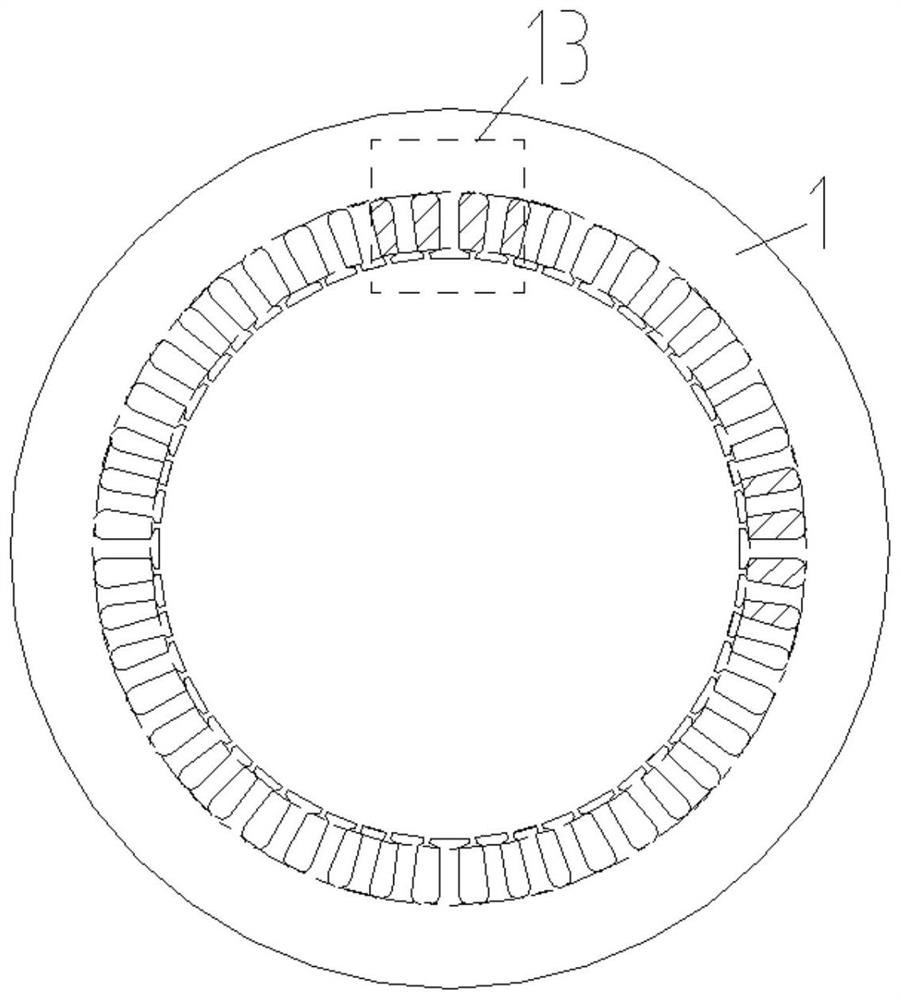

[0029] see in conjunction Figure 1 to Figure 11As shown, according to an embodiment of the present invention, a motor stator is provided, including a stator core 1, and N stator slots 11 are constructed on the stator core 1, and the pole pairs of the motor rotor matched with the motor stator The number is p, and the N stator slots 11 are sequentially divided into 6p stator slot groups along the first direction, and each stator slot group includes q stator slots 11 sequentially arranged along the first direction, q groups The unilateral coils on the same side of the sinusoidal winding (not shown in the figure) using the lap winding method are respectively embedded in the q stator slots 11 in each stator slot group, q=N / 6p, the slot area of the q stator slots 11 in each stator slot group decreases from the central stator slot 11 to the stator slots 11 on both sides, and the stator slot 11 with the largest area among the q stator slots 11 corresponds to the q group The coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com