Series excited motor and speed regulation and control method thereof

A technology of series excitation motor and control method, applied in excitation or armature current control, electrical components, electromechanical devices, etc., can solve the problems of increasing harmonic current components, failing to pass certification tests, etc., to reduce harmonic current components , the effect of reducing the jump and reducing the harmonic current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

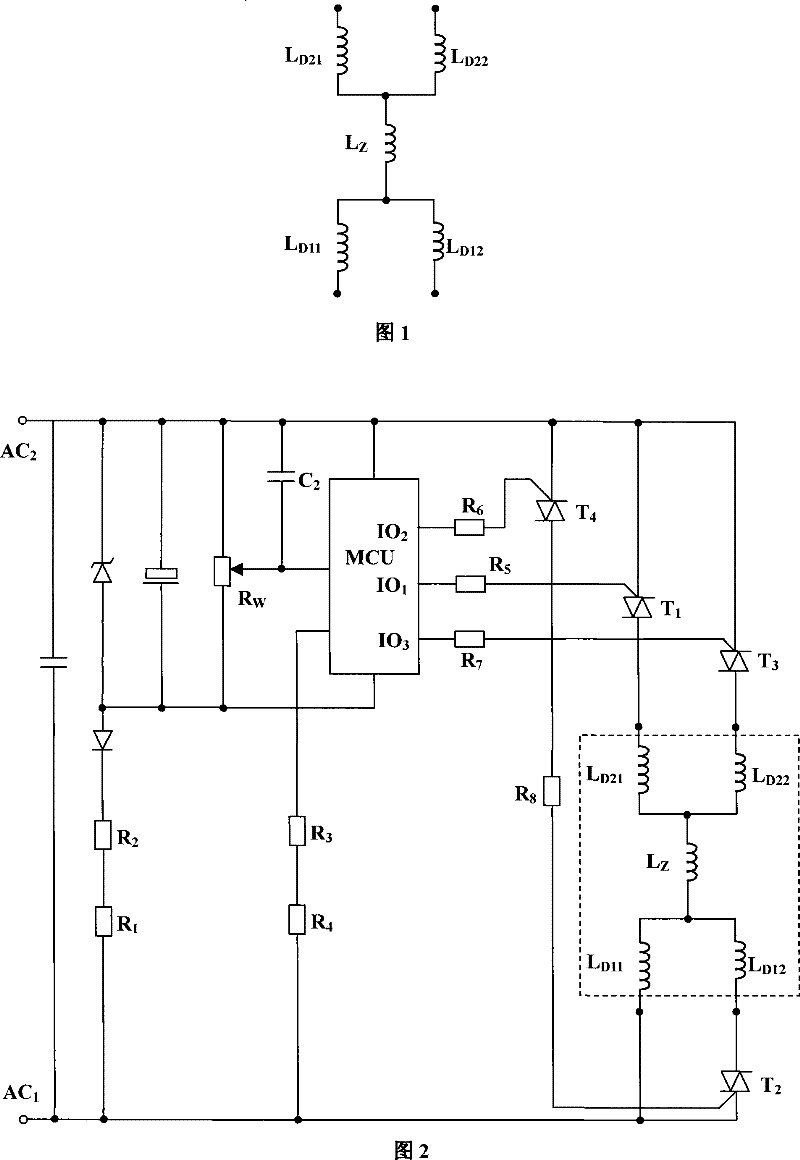

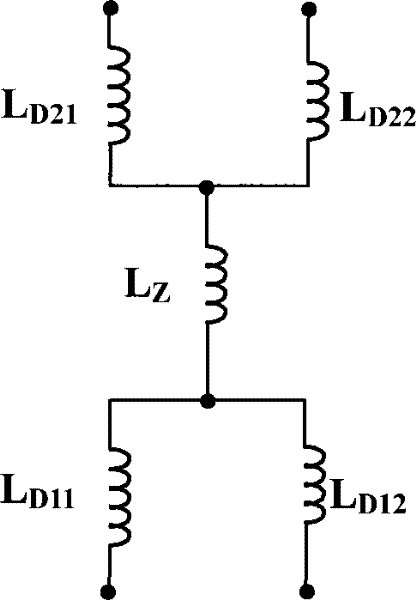

[0024] Embodiment one: see attached figure 1 As shown in Figure 7,

[0025] See attached figure 1 As shown, a series motor includes a rotor and a stator, and the rotor is provided with an armature winding L Z , the two poles of the stator are provided with field windings respectively, and a series circuit is formed between the field winding and the armature winding through brushes, wherein the field winding of one pole is formed by the low section winding L D11 and high section winding L D12 Composed of double winding structure, the low section winding L D11 and high section winding L D12 One end of the pole is connected to the brush, and the other end constitutes an independent outlet. The direction of the magnetic field generated by the low-section winding and the high-section winding is the same after the power is applied; the excitation winding of the other pole is formed by the low-section winding L D21 and high section winding L D22 Composed of double winding struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com