A two-way slapping device for down jackets for uneven distribution of down and fluff

A technology for uneven distribution and down jackets, which is applied to clothing, clothing, and tools for sewing clothes, etc. It can solve the problems of dust generated by beating, uneven distribution of down and down, and effort, and achieve the effect of easy storage and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

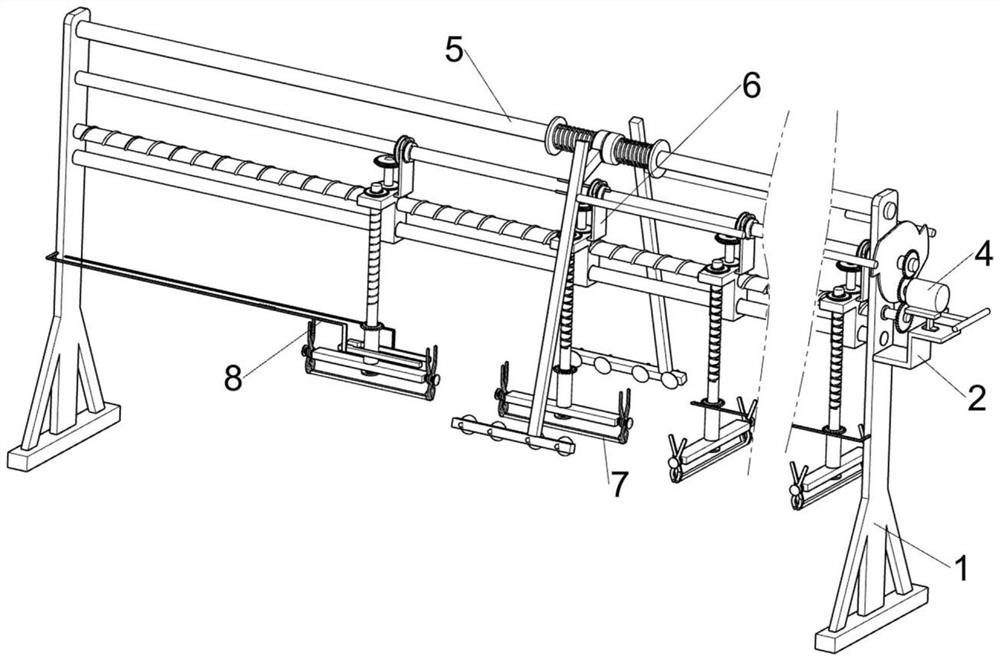

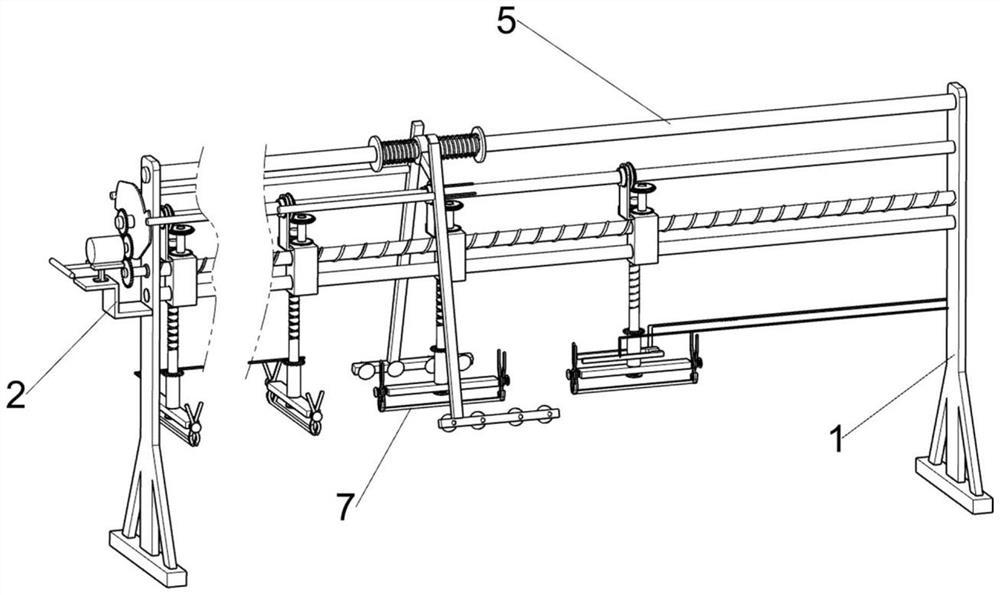

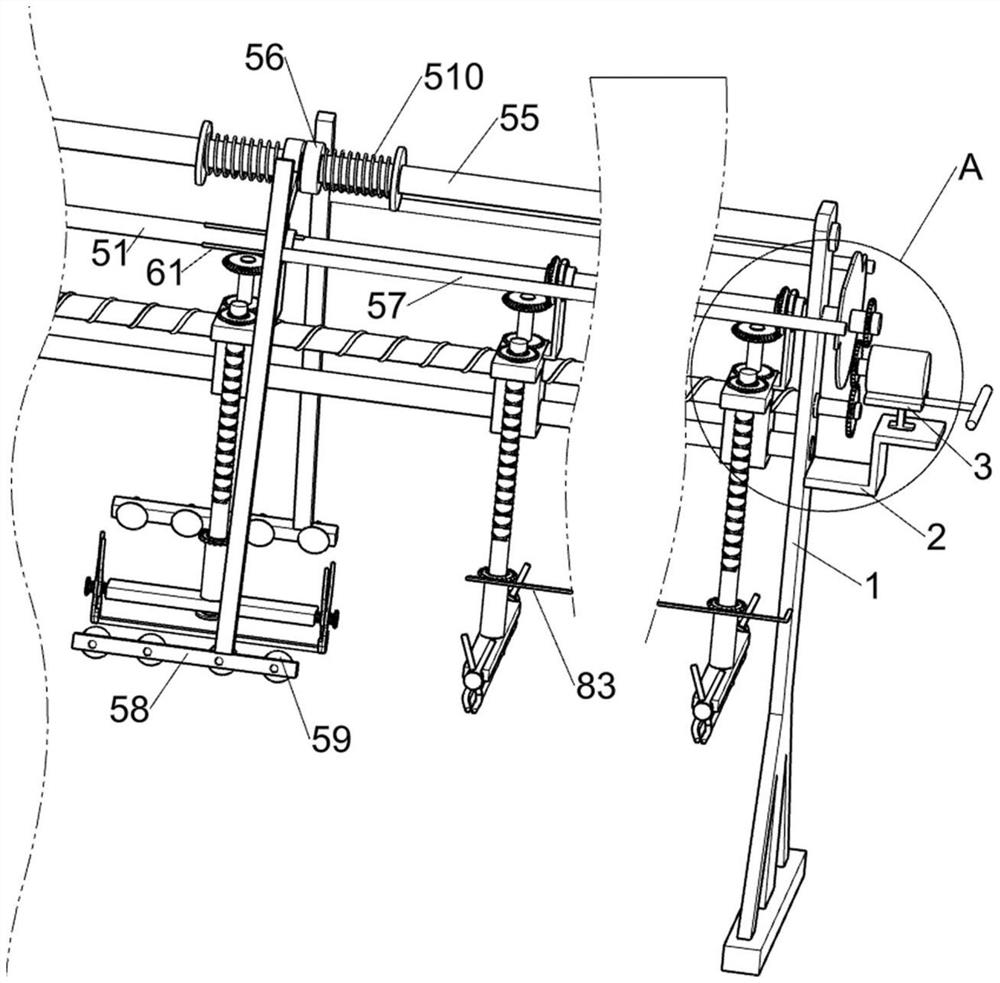

[0022] Example: a bidirectional flapping device for down jackets with uneven distribution of down and down, such as Figure 1-6 As shown, it includes a supporting plate 1, a supporting plate 2, a pull rod 3, an intermittent moving component 4, a beating component 5, a lifting component 6, a clamping component 7 and a turning component 8, and a supporting plate 1 is fixed on one side of the supporting plate 2, the support plate 2 is slidably connected with a pull rod 3, and the two support plates 1 are provided with intermittent moving components 4, and the beating components 5 used to beat the down jacket are also arranged on the two supporting plates 1, and the intermittent moving components 4 are provided with There is a lifting assembly 6, the lifting assembly 6 is used to reciprocate the down jacket up and down, the clamping assembly 7 is arranged on the lifting assembly 6, the clamping assembly 7 is used for clamping the down jacket, and the support plate 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com