Collaborative robot pipeline package

A technology for conduit packs and robots, which is applied in the field of robots and can solve the problems of unsatisfactory cable protection, difficult cable routing, and difficult installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

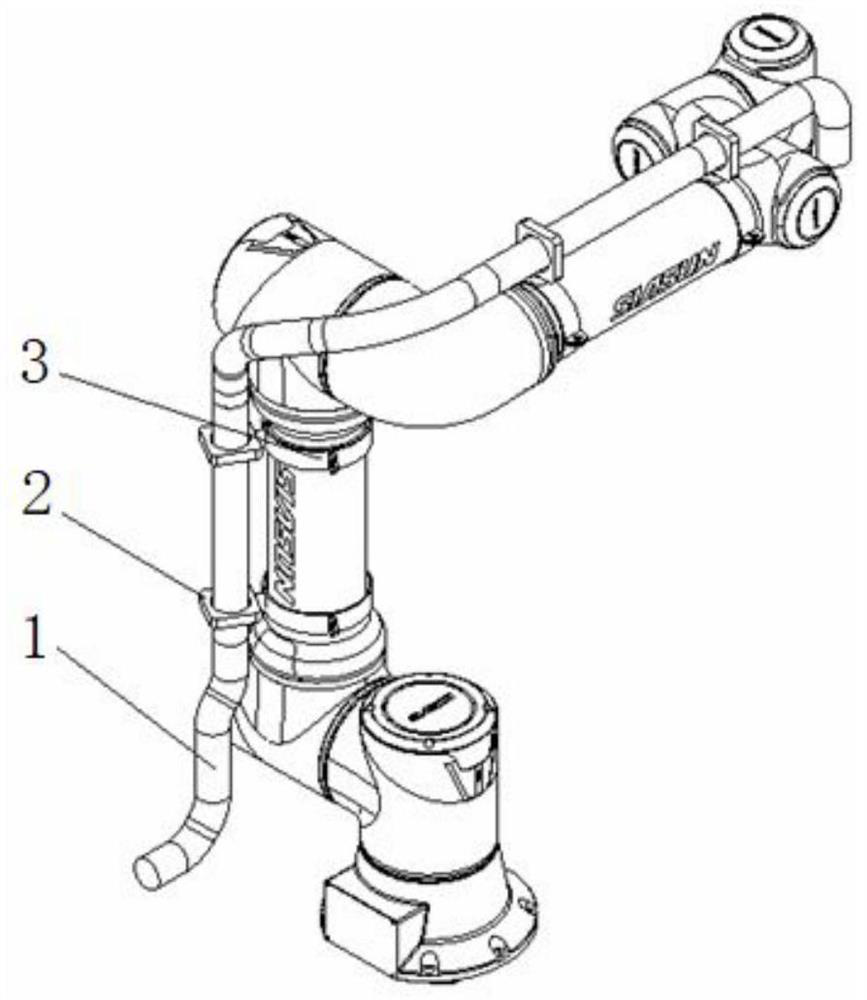

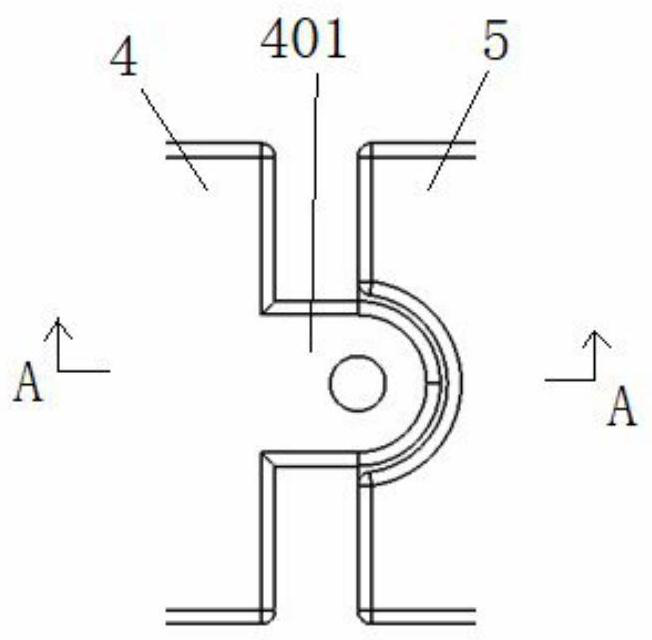

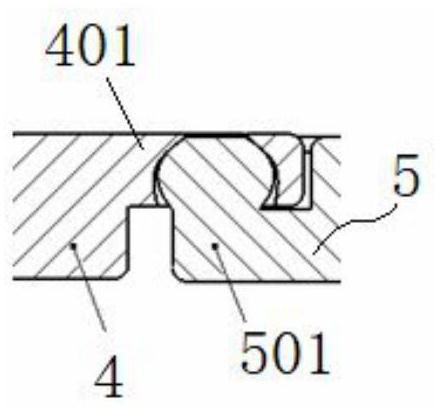

[0019] like Figure 1~5 As shown, the present invention includes a three-dimensional drag chain 1, a drag chain joint 2 and a pipe clamp 3, wherein the pipe clamp 3 is fixed on the robot body, the drag chain joint 2 is fixedly connected with the corresponding pipe clamp 3, and the three-dimensional drag chain 1 passes through each drag chain The link head 2 is supported and fixed, and the three-dimensional drag chain 1 includes a plurality of drag chain links, and as Figure 2~3 As shown, the adjacent towline links are connected by a detachable buckle groove structure, and the positions of each towline link can be adjusted according to needs, so as to be suitable for the routing requirements of robots of different shapes, such as Figure 4 As shown, a through hole is provided in the middle of the drag chain joint 2, and one side of the drag chain joint 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com