Rapid packaging device for charging pile production

A charging pile, fast technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low efficiency, low efficiency of foam tape, manual operation is difficult to unify the position of glue, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

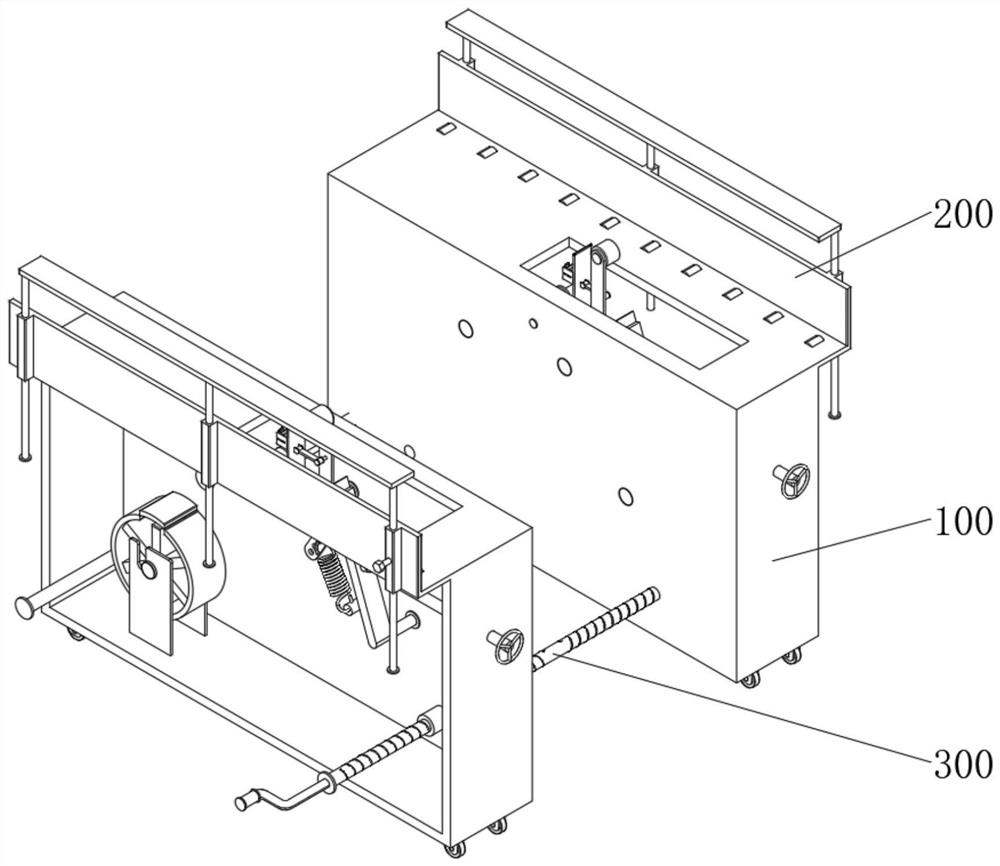

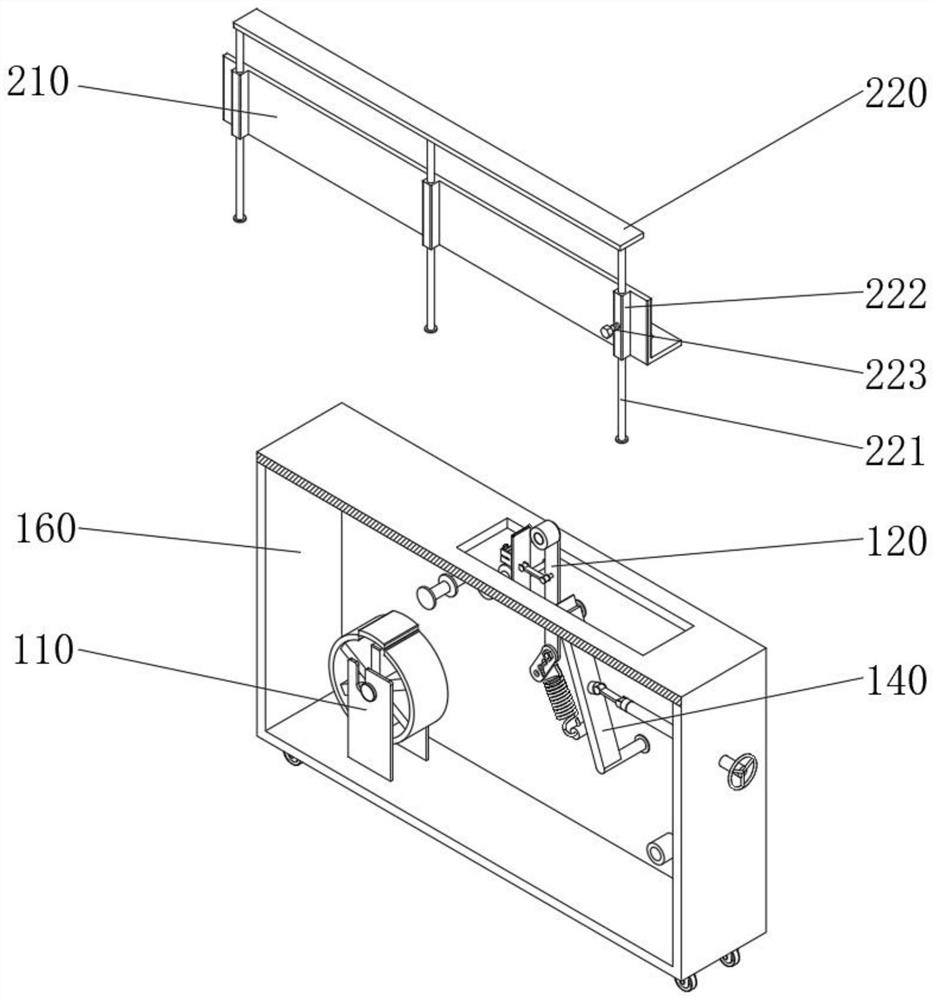

[0054] see Figure 1-Figure 10 As shown, a rapid packaging device for charging pile production is provided, including a symmetrically arranged gluing device 100, a positioning device 200 installed above the gluing device 100 and an adjusting device 300 located below the gluing device 100, and the gluing device 100 including at least:

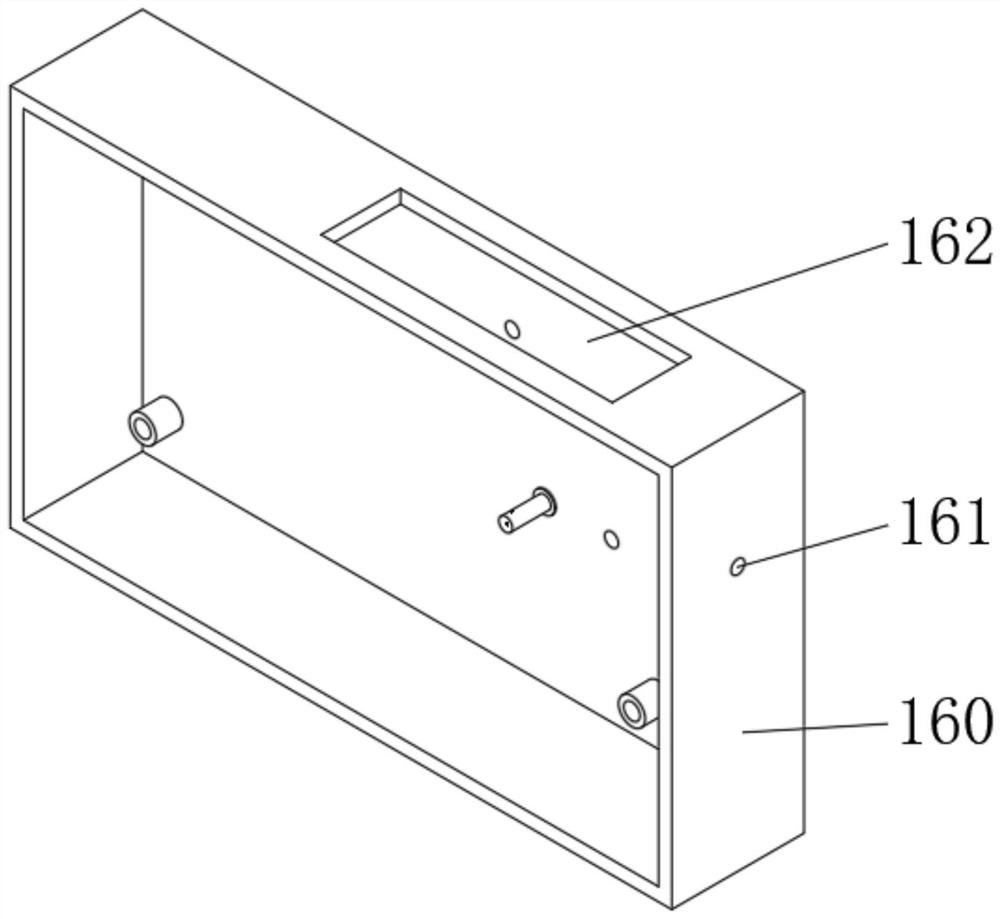

[0055] Glue release structure 110, the glue release structure 110 includes a pair of fixed plates 111, a box body 160 is connected below the fixed plate 111, the box body 160 is a box body structure with open sides, and a working groove 162 is provided above the box body 160. A pair of fixed plates A sleeve 113 is arranged between the plates 111, and a rotating rod 114 is fixedly connected to both sides of the sleeve 113, and a slot 112 is opened on the fixed plate 111, and the rotating rod 114 is connected in the slot 112 for rotation;

[0056] The glue-pressing structure 120, the glue-pressing structure 120 includes a glue-releasing plate 121...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com