Film roll cutting and packaging equipment and using method thereof

A technology for packaging equipment and film rolls, applied in the field of film roll cutting and packaging equipment, can solve problems such as low efficiency, time-consuming and laborious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

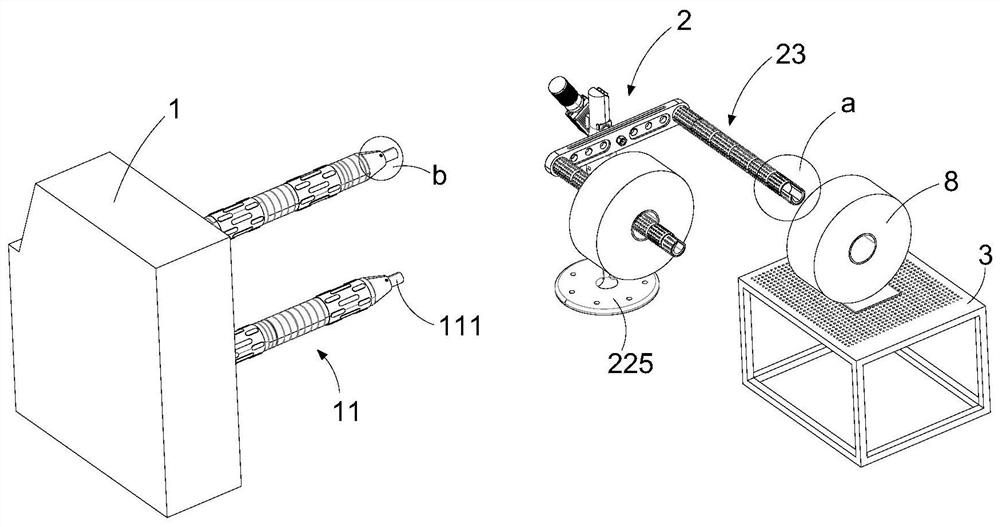

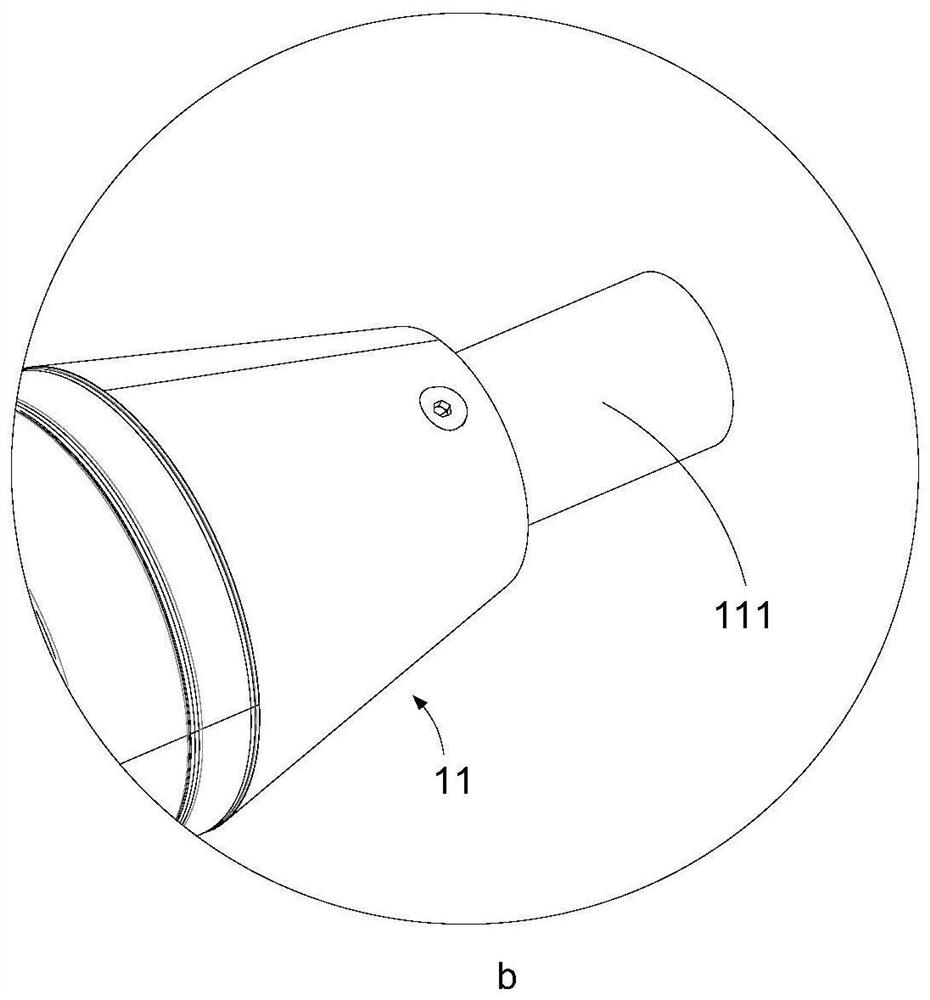

[0046] Such as Figure 1-Figure 8 As shown, the present invention provides a film roll cutting and packaging equipment, including a film cutting machine 1 , a film roll transfer device 2 and a packaging table 3 . The film cutter 1 and the packaging table 3 are located on both sides of the film roll transfer device 2. Generally, the connection line between the film cutting machine 1 and the film roll transfer device 2 is perpendicular to the connection line between the packaging table 3 and the film roll transfer device 2 . That is to say, the film roll transfer device 2 can swing between the film cutting machine 1 and the packaging table 3 by swinging 90°. The film cutting machine 1 is provided with a loading rod 11 . The cut film roll 8 is located on the loading bar 11 .

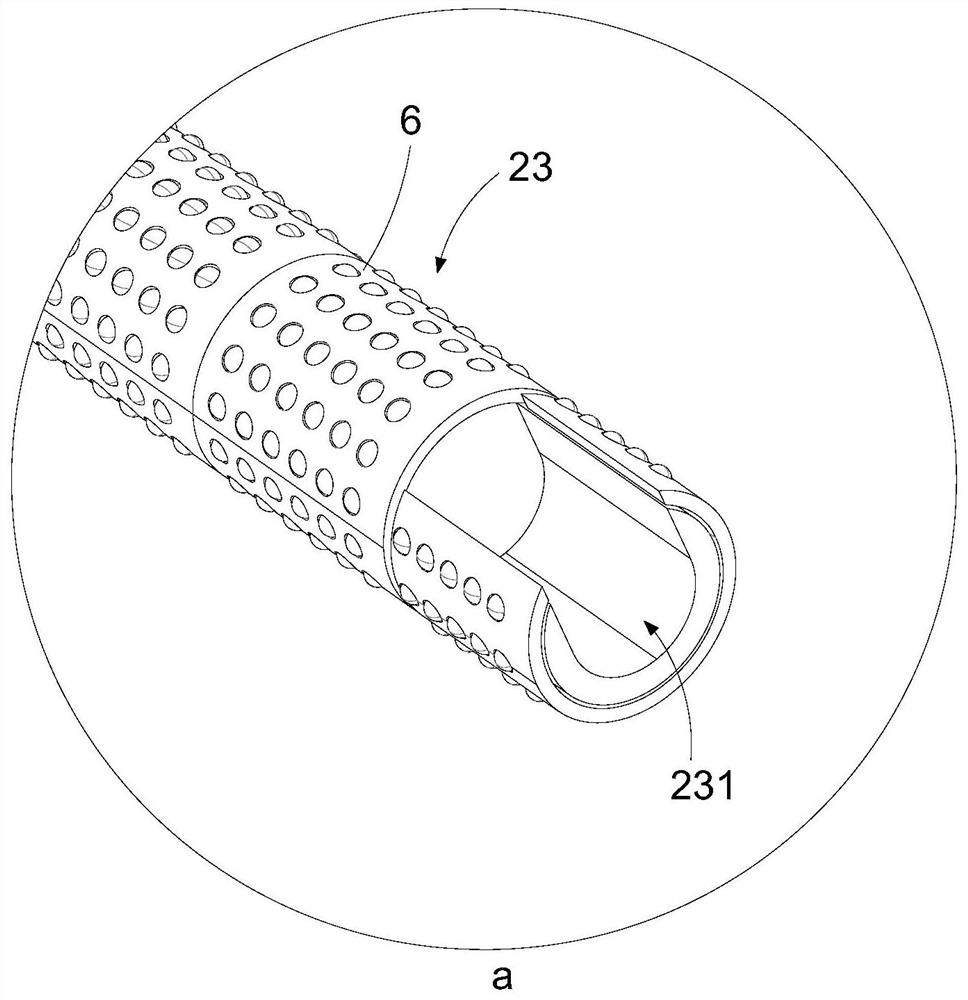

[0047] The film roll transfer device 2 includes a drive device 21 , a support 22 and a transfer rod 23 . The transfer rod 23 is rotatably disposed on the bracket 22 so that the transfer rod 23 can be do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com