Metal window frame with cleaning device

A technology for cleaning device and window frame, applied in the direction of window/door frame, window/door, cleaning equipment, etc., can solve problems such as difficulty in cleaning the exterior of glass windows, poor appearance of windows, affecting indoor lighting effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

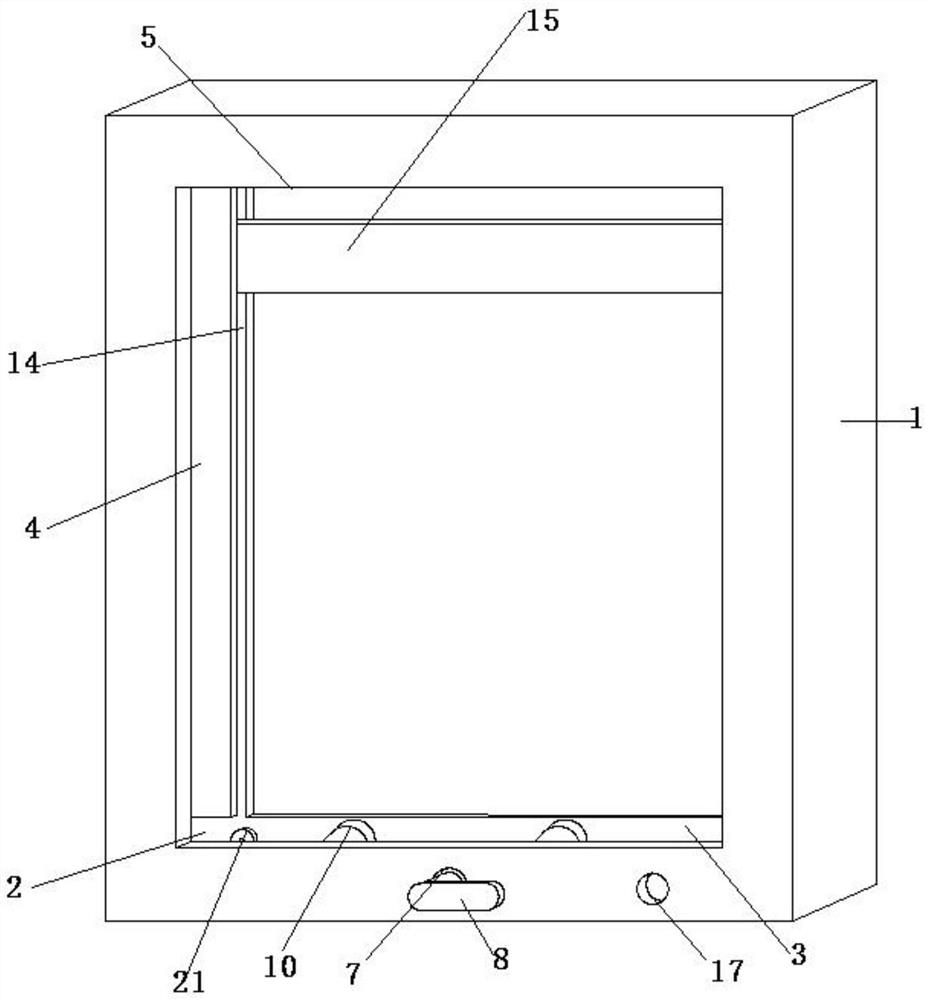

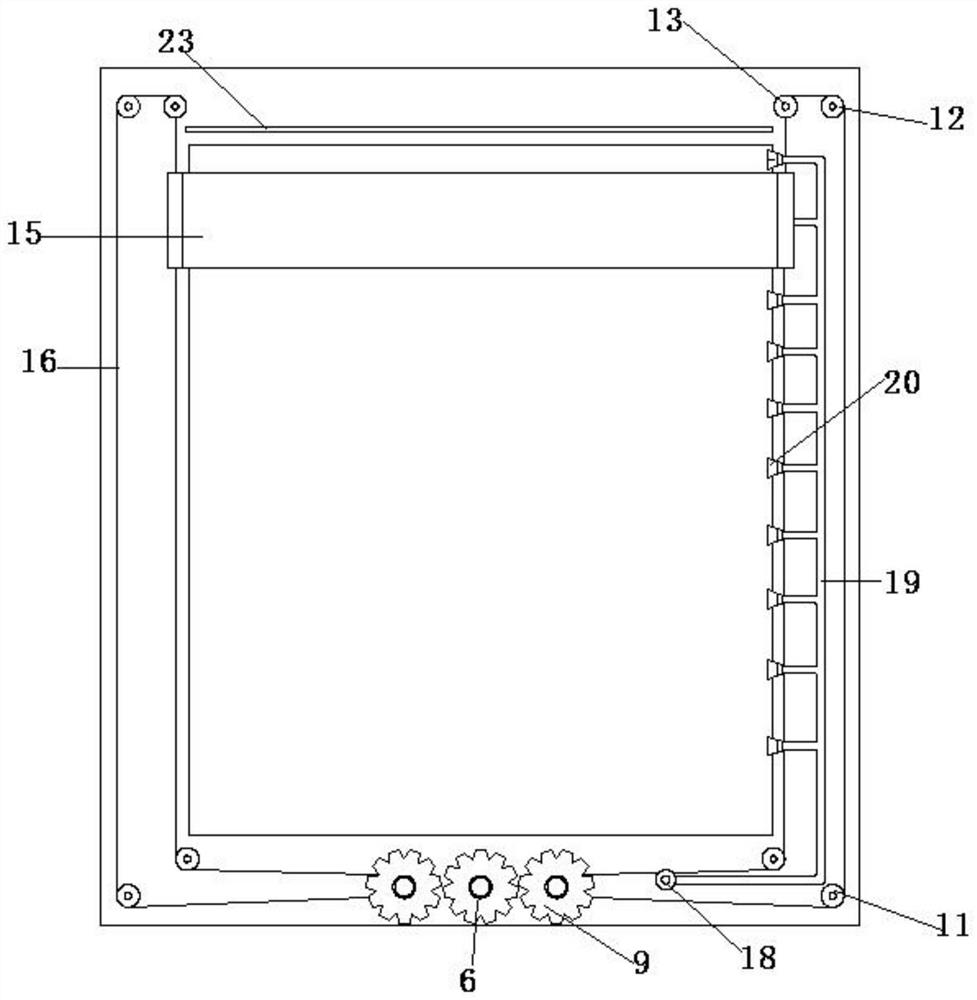

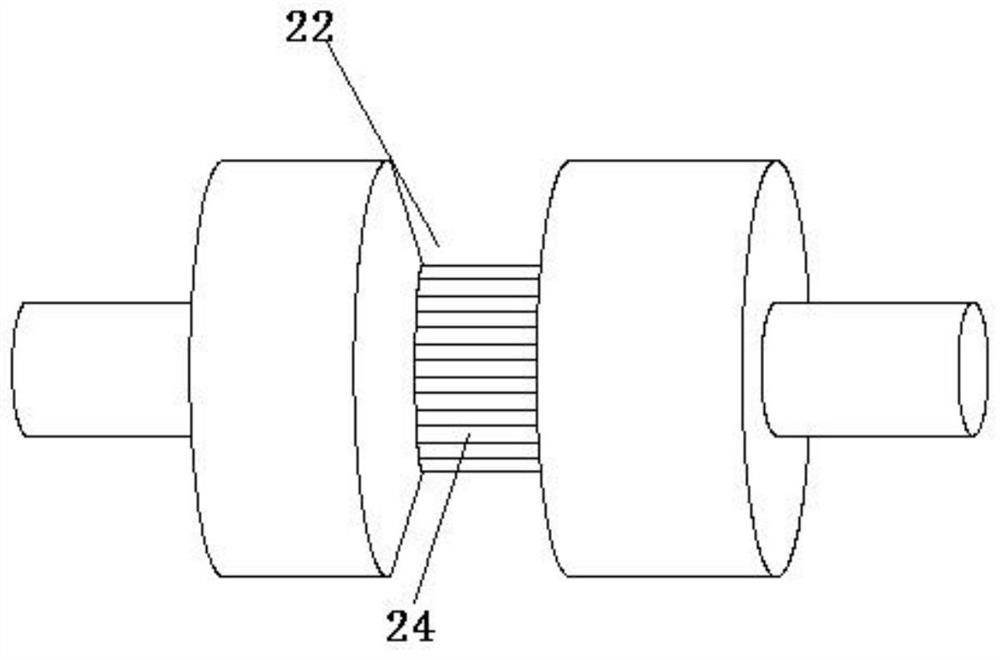

[0016] Such as figure 1 and figure 2 A metal window frame with a cleaning device is shown, which includes a window frame body 1, and the inside of the window frame body 1 is provided with an installation groove 2, and the installation groove 2 includes a bottom groove 3, a side groove 4 and a top groove 5, The bottom groove 3, the side groove 4 and the top groove 5 are connected, and the bottom groove 3 is provided with a driving gear 6, and the driving gear 6 is installed on the rotating shaft, and the end of the rotating shaft is fixed by a two-way damping bearing 7 On the window frame body 1, the rotating shaft is connected with the handle 8, and the handle 8 is located outside the bottom groove 3, and driven gears 9 are provided on both sides of the driving gear 6, and can be meshed with it for transmission. The driven gear 9 is located inside the bottom groove 3. One end of the driven gear 9 is connected to the window frame body 1 through a bearing, and the other end is...

Embodiment 2

[0018] Such as Figure 1-Figure 3 A metal window frame with a cleaning device is shown, which includes a window frame body 1, and the inside of the window frame body 1 is provided with an installation groove 2, and the installation groove 2 includes a bottom groove 3, a side groove 4 and a top groove 5, The bottom groove 3, the side groove 4 and the top groove 5 are connected, and the bottom groove 3 is provided with a driving gear 6, and the driving gear 6 is installed on the rotating shaft, and the end of the rotating shaft is fixed by a two-way damping bearing 7 On the window frame body 1, the rotating shaft is connected with the handle 8, and the handle 8 is located outside the bottom groove 3, and driven gears 9 are provided on both sides of the driving gear 6, and can be meshed with it for transmission. The driven gear 9 is located inside the bottom groove 3. One end of the driven gear 9 is connected to the window frame body 1 through a bearing, and the other end is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com