An embossing device for jeans with colorful patterns

A technology for jeans and patterns, applied in printing, printing presses, rotary printing presses, etc., can solve problems such as reducing work efficiency and increasing costs, and achieve the effect of improving quality and uniform printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

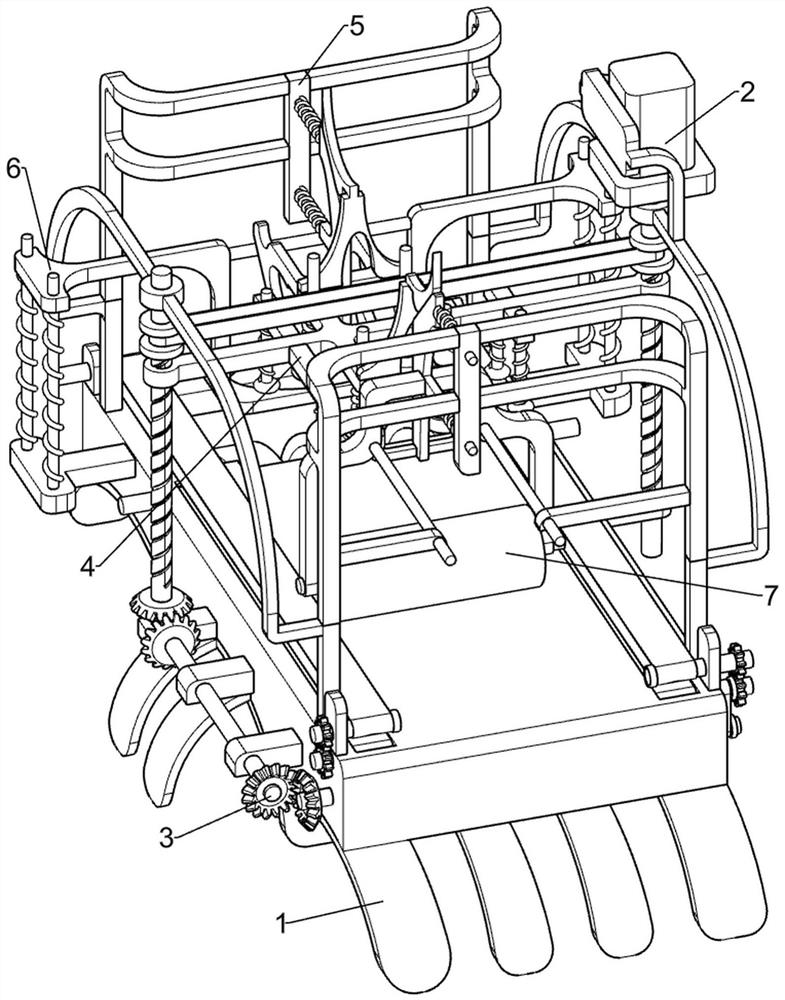

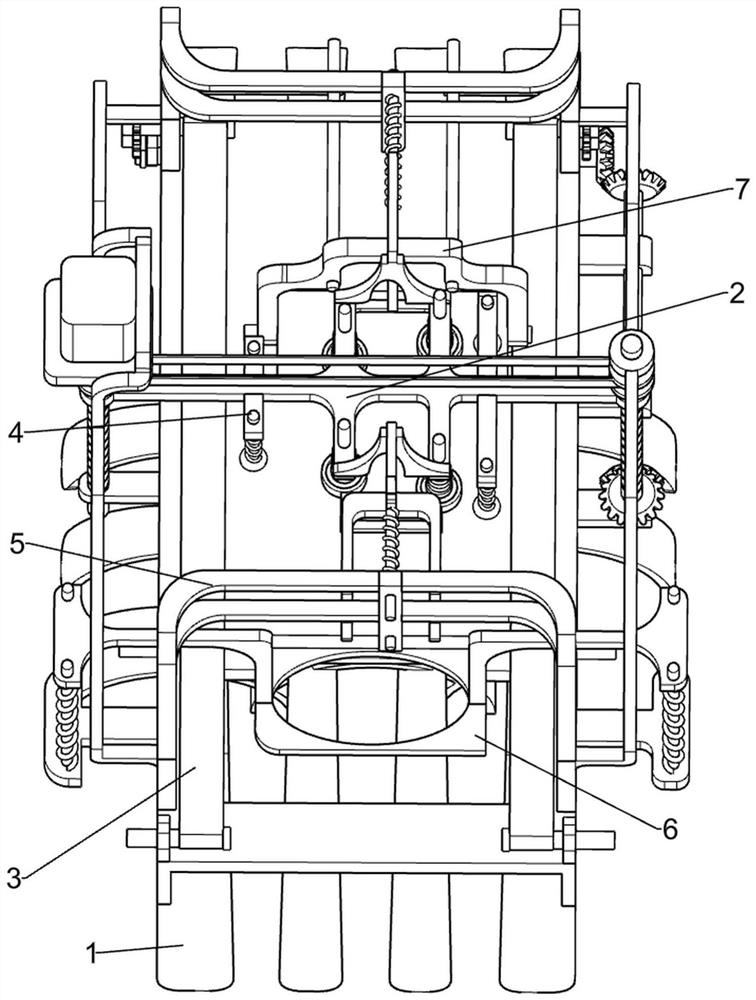

[0079] An embossing device for jeans with colorful patterns, such as figure 1 and figure 2 As shown, it includes a base frame 1, a first sliding rod 11, a pattern printing block 12, a first spring 13, a printing mechanism 2 and a conveying mechanism 3. The base frame 1 is provided with a printing mechanism 2, and the printing mechanism 2 is provided with a sliding device There are four first sliding rods 11 , the bottom of the first sliding rod 11 is provided with a pattern block 12 , a first spring 13 is connected between the pattern block 12 and the printing mechanism 2 , and the first spring 13 is wound around the first sliding rod 11 On the top, the printing mechanism 2 is provided with a conveying mechanism 3 .

[0080] When people need to emboss the jeans with patterns, they can use this kind of jeans embossing device with colorful patterns. People put the jeans to be printed on the conveying mechanism 3, and then start the printing mechanism 2, and the printing mechan...

Embodiment 2

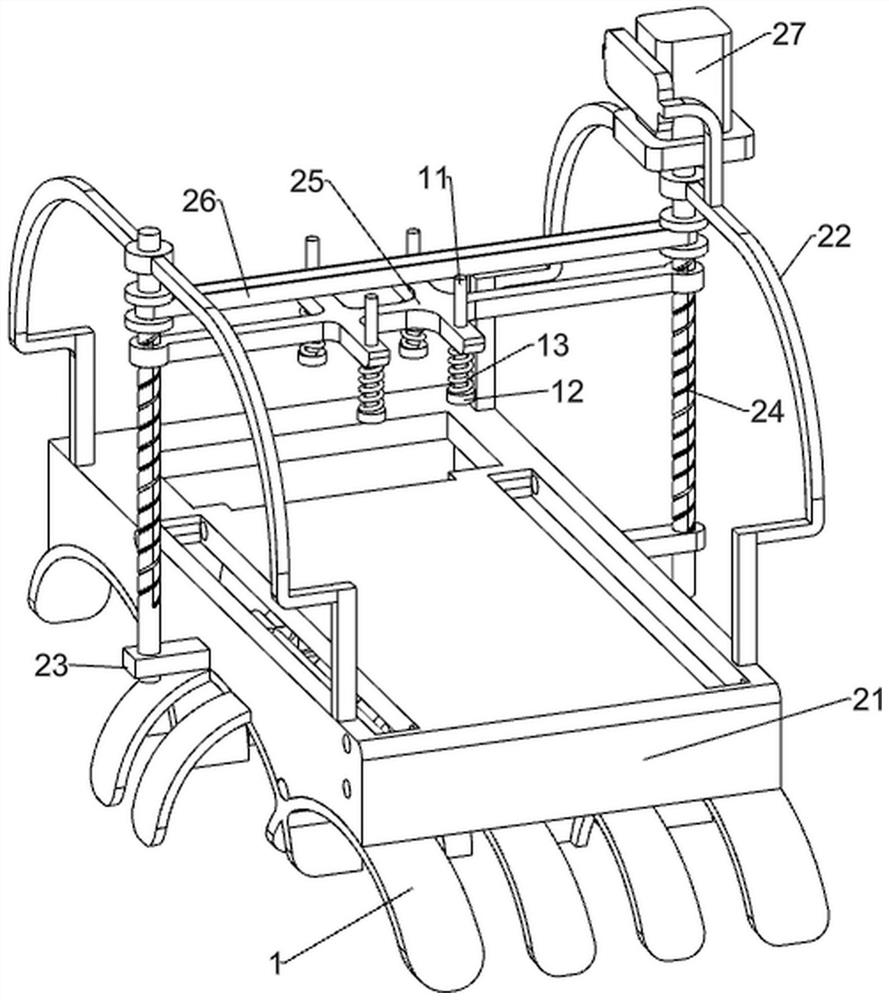

[0082] On the basis of Example 1, as image 3 and Figure 4 As shown, the printing mechanism 2 includes a mounting plate 21, a fixed frame 22, a first support block 23, a screw 24, a moving plate 25, a first transmission belt 26 and a servo motor 27, and the base frame 1 is provided with a mounting plate 21, The mounting plate 21 is provided with fixing frames 22 on the left and right sides. The left and right sides of the mounting plate 21 are provided with first support blocks 23. The two first support blocks 23 are provided with screw rods 24 in a rotatable manner. A servo motor 27 is installed on the right side of the upper part of the frame 22. The output shaft of the servo motor 27 is connected with the screw rod 24 on the right side. A first transmission belt 26 is wound between the two screw rods 24. The two screw rods 24 are threadedly connected. There is a moving plate 25 , the moving plate 25 is slidably connected with the first sliding rods 11 , the number of the ...

Embodiment 3

[0087] On the basis of Example 2, as Figure 5-8 As shown, it also includes a pressing mechanism 4. The pressing mechanism 4 includes a second support block 41, a second sliding rod 42, a top block 43 and a second spring 44. The left and right sides of the moving plate 25 are provided with second supports Block 41, the second support block 41 is slidably provided with a second sliding rod 42 on both the front and rear sides, the bottom of the second sliding rod 42 is provided with a top block 43, and a second spring is connected between the top block 43 and the second support block 41 44 , the second spring 44 is wound around the second sliding rod 42 .

[0088] The downward movement of the moving plate 25 drives the second support block 41 to move downward, thereby driving the second sliding rod 42 and the top block 43 to move downward. When the top block 43 contacts the jeans, the second spring 44 is compressed and reaches the pressure. The tightening effect facilitates the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com