Anti-loose anti-bending automatic compensation fastening bolt structure of large clean energy equipment

A technology of clean energy and fastening bolts, applied in the direction of bolts, screws, nuts, etc., can solve the problems of easy safety hazards, easy loosening, and low bending fatigue strength, so as to improve the bending fatigue strength, prevent self-loosening, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

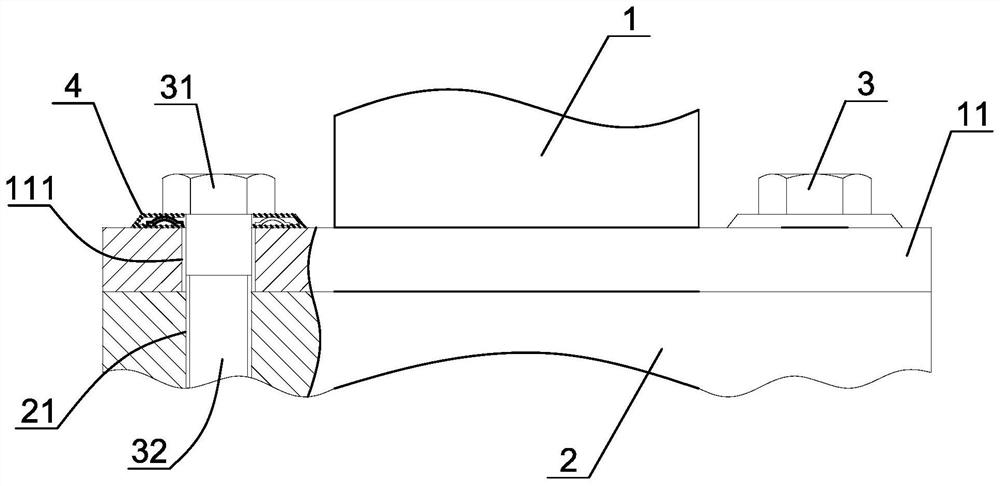

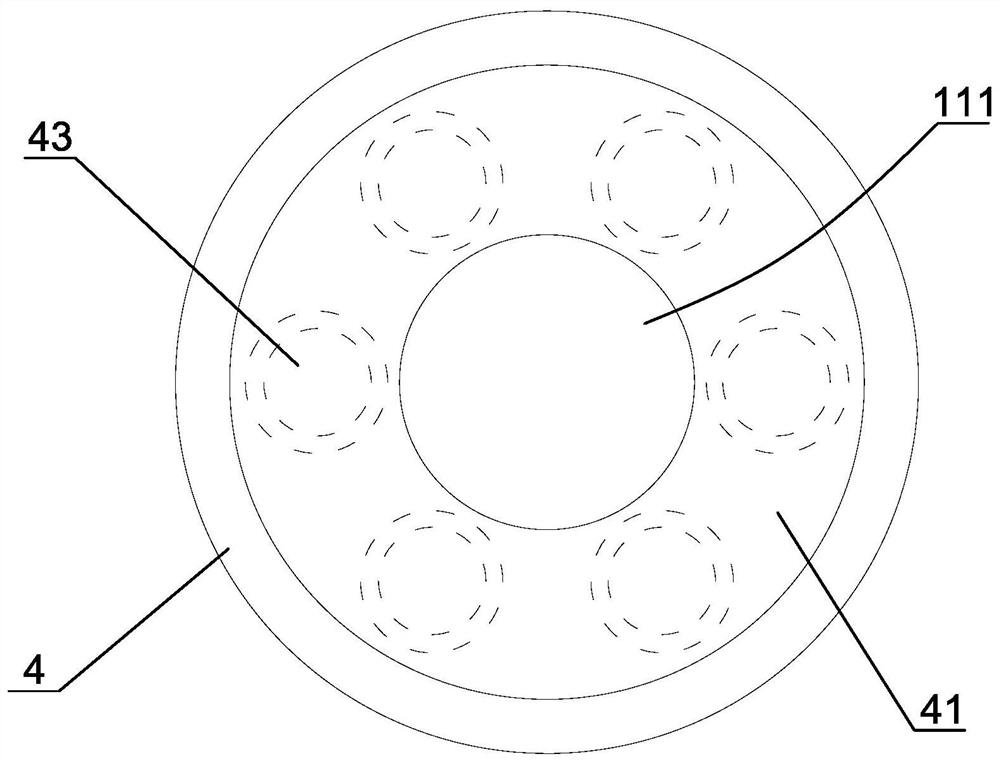

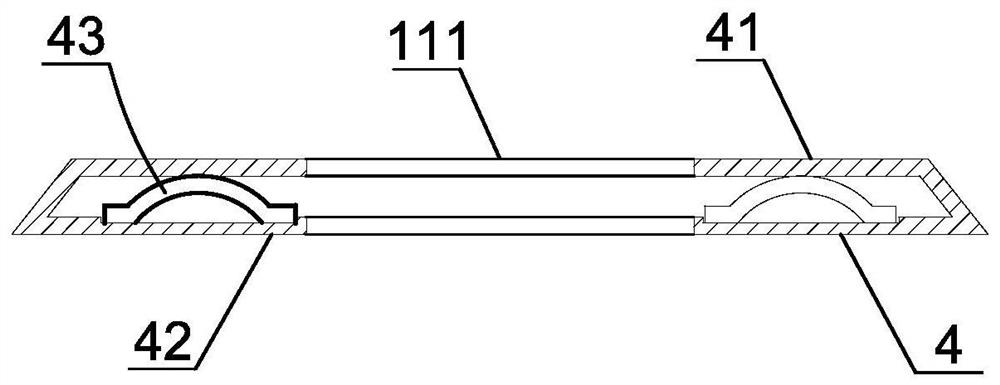

[0040] Such as figure 1 As shown, a large-scale clean energy equipment anti-loosening anti-bending automatic compensation bolt structure includes a first rotating part 1 and a second rotating part 2 that need to be connected. The first rotating part and the second rotating part can be water turbines The rotating shaft of the generator, the rotor shaft of the generator, etc. In order to facilitate the coaxial connection of the first rotating part and the second rotating part, at least one end of the first rotating part is connected with a connecting flange 11, and several connecting flanges are provided on the connecting flange for connecting the first rotating part and the second rotating part. And in the bolt through holes 111 arranged at intervals in the circumferential direction, the bolt through holes are provided with the bolts 3 with bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com