Pipe fitting connecting flange

A technology for connecting flanges and pipe fittings, which is applied in the direction of flange connections, pipes/pipe joints/pipe fittings, passing components, etc., which can solve the problems of low installation efficiency, low connection tightness, and long overall process time, and improve the tightness and stability, improve installation efficiency, and expand the effect of adapting the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

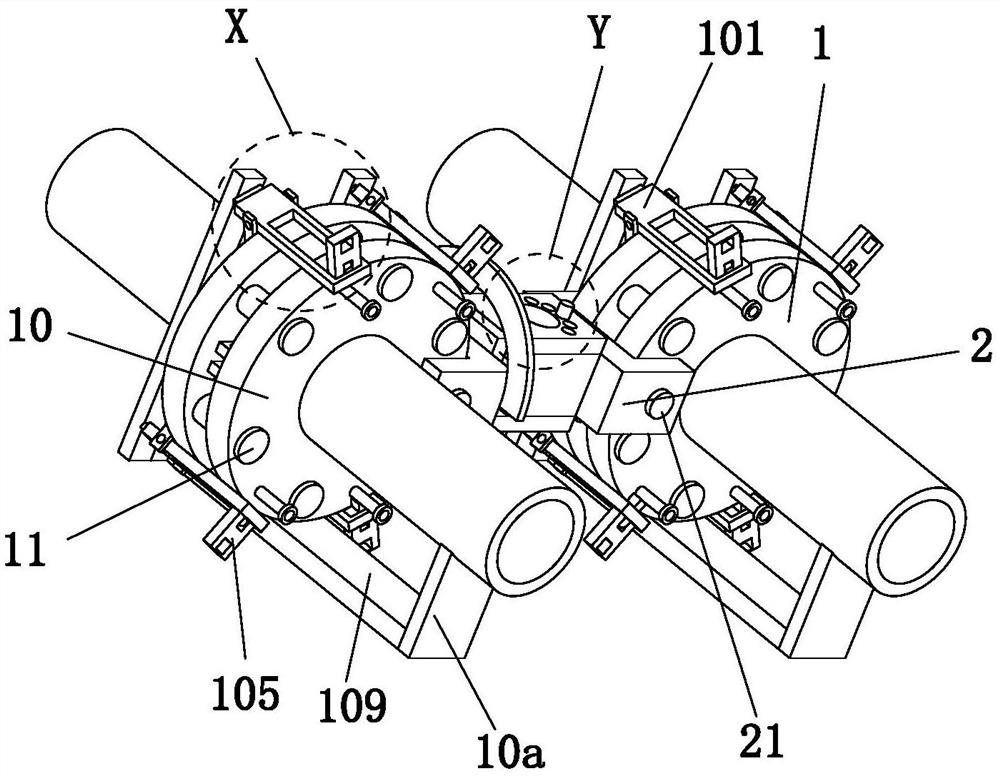

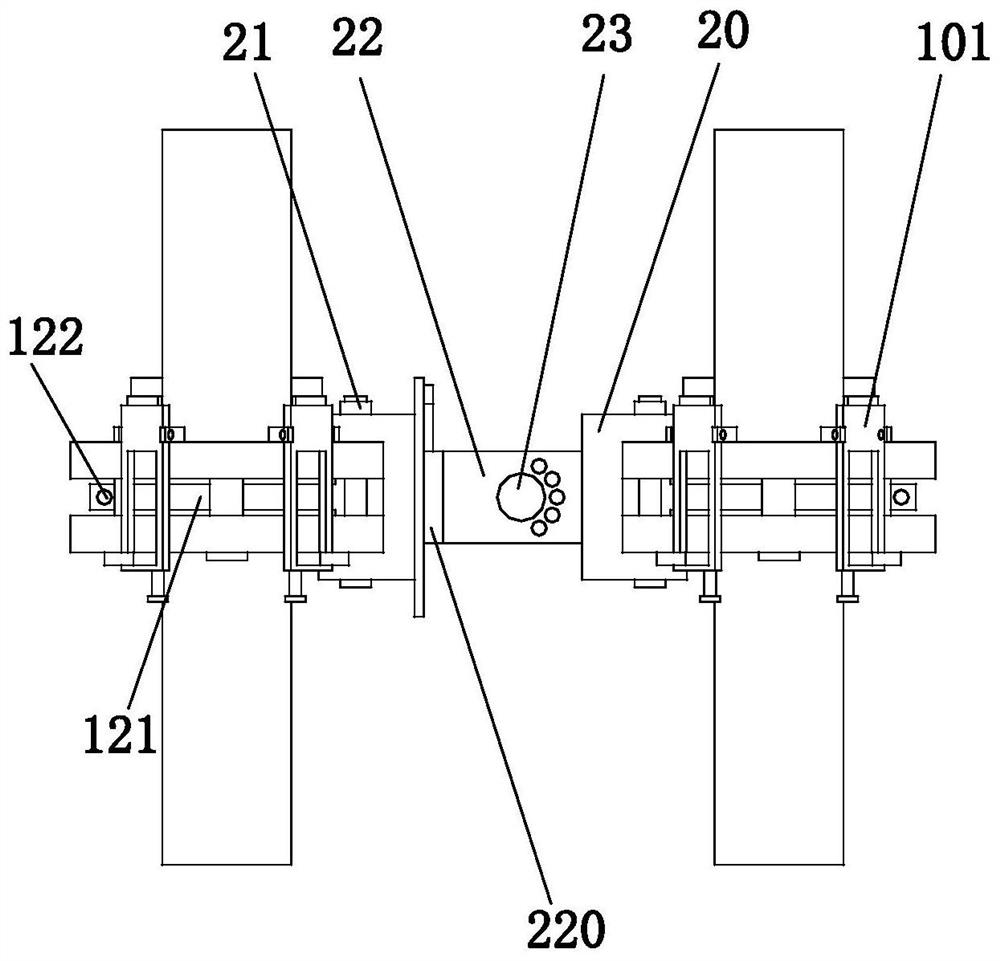

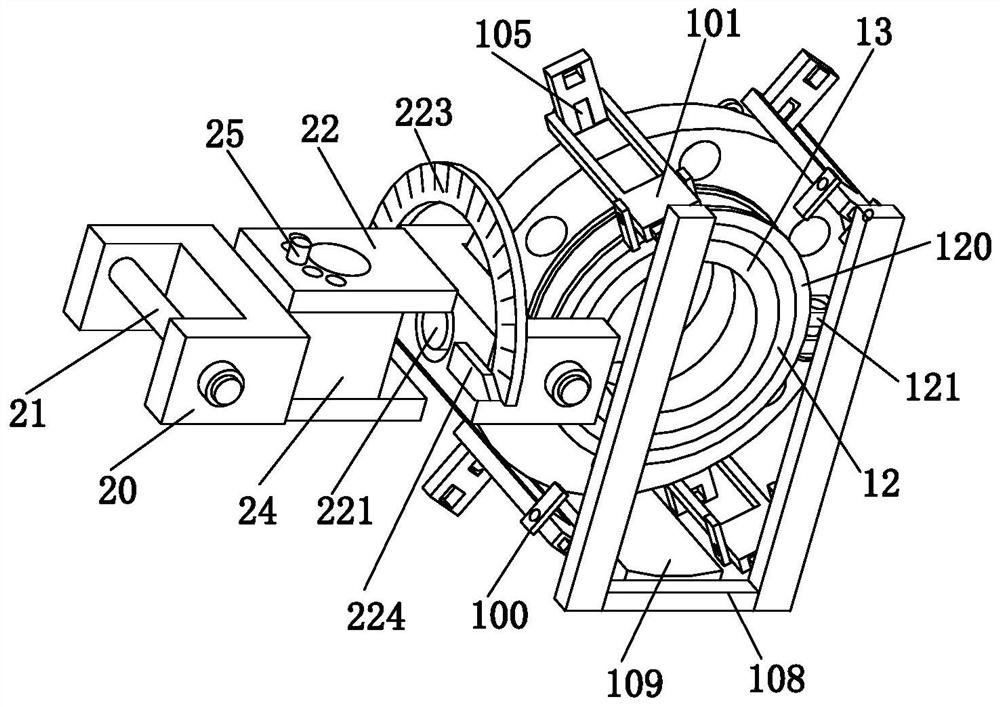

[0033] Such as Figure 1 to Figure 10 As shown, a connecting flange of a pipe fitting includes a clamping mechanism 1 and a connecting mechanism 2. The clamping mechanisms 1 are symmetrically arranged left and right, and a connecting mechanism 2 is arranged between the clamping mechanisms 1 .

[0034] The clamping mechanism 1 includes a flange body 10, a connecting bolt 11, a No. 1 snap ring 12, a No. 2 snap ring 13, a block 14 and a spring 15, and the No. 2 snap ring 13 is sleeved on a Inside the No. 1 snap ring 12, the rear end of the No. 1 snap ring 12 and the front end of the No. 2 snap ring 13 are all equipped with a flange body 10, and a No. 1 through hole is provided on the front end of the No. 1 snap ring. The holes are evenly arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com